Model F53 Flow Monitor/Totalizer (universal-mount 1/2 DIN) Rev. 1-201

10

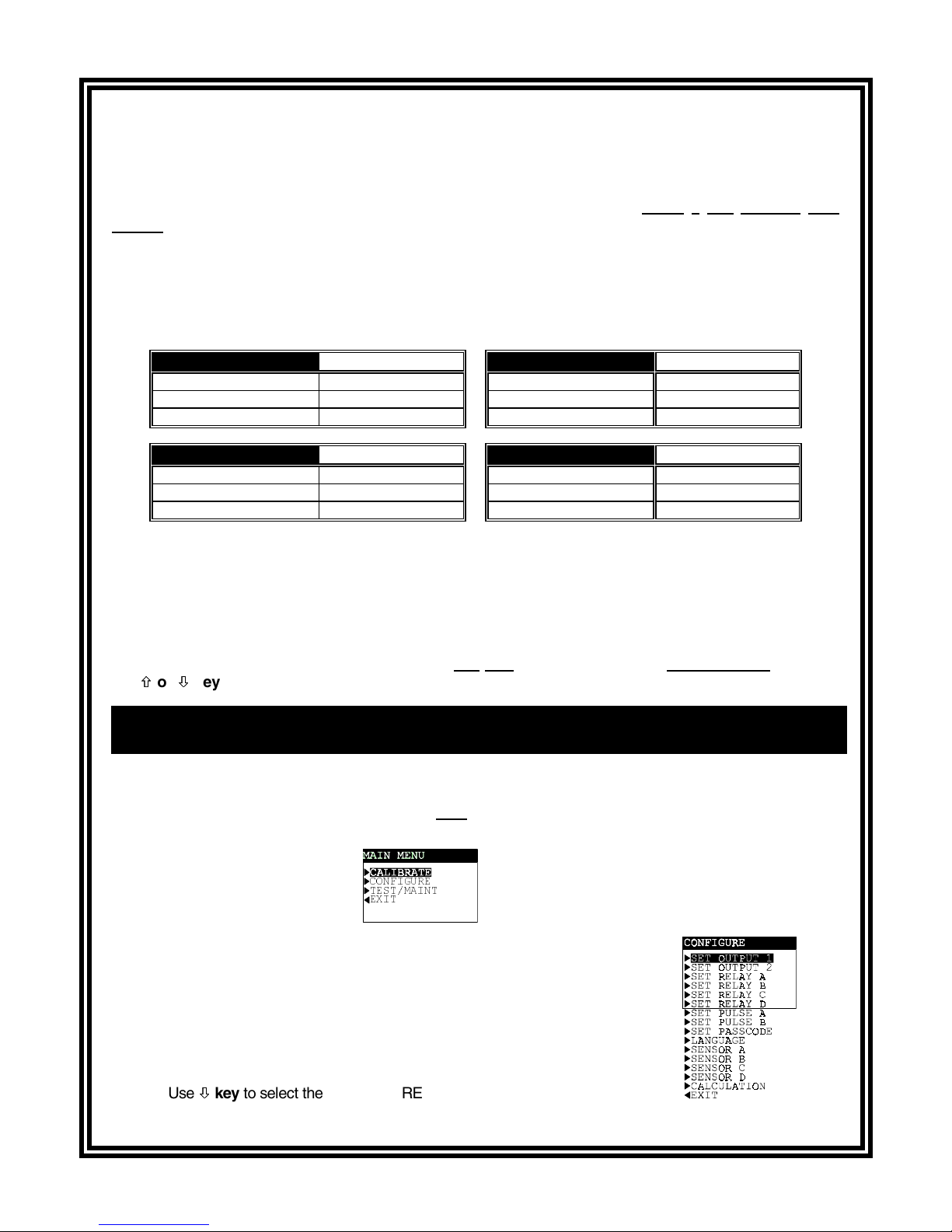

TABLE OF CONTENTS (continued)

SECTION 3 ADJUSTING DISPLAY CONTRAST.............................................................36

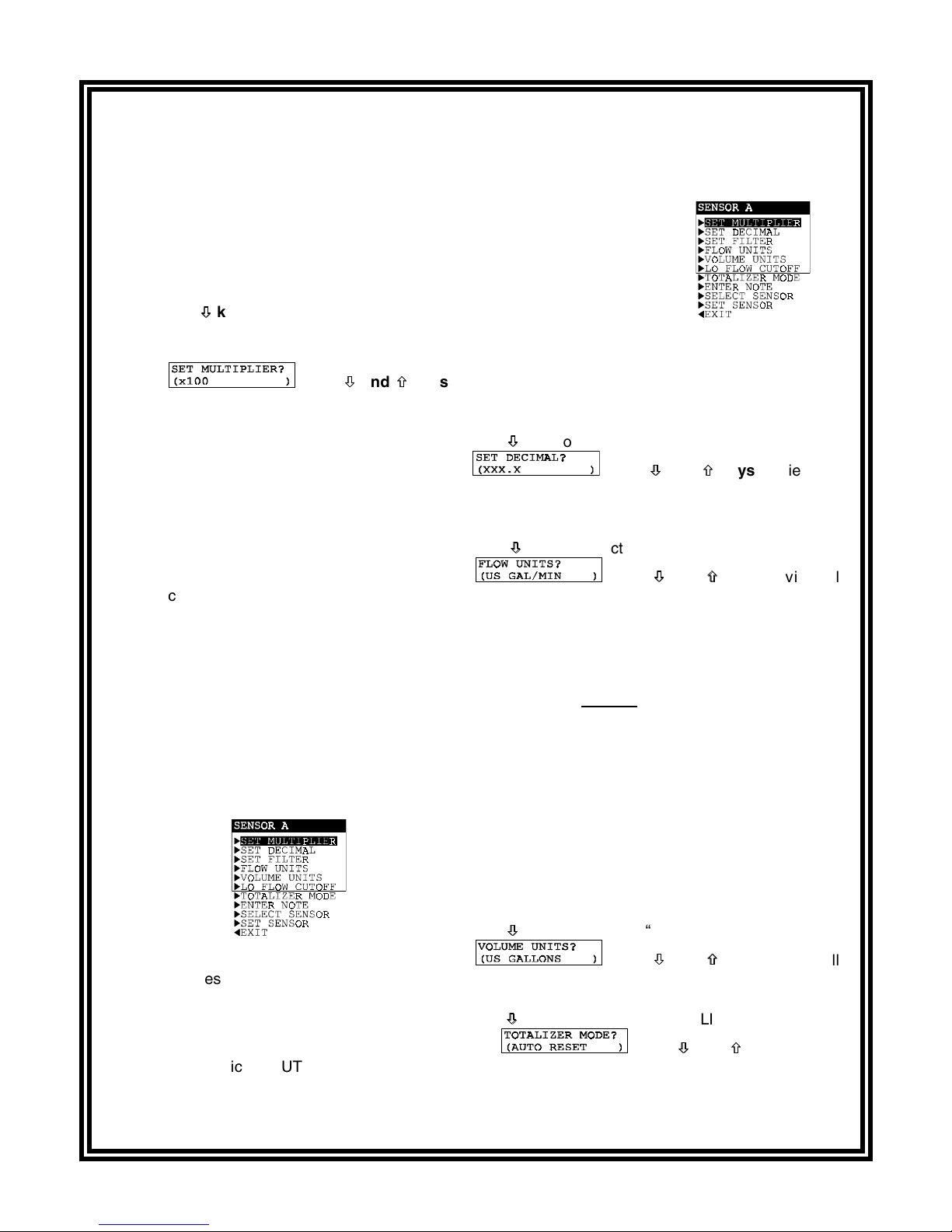

SECTION 4 ANALYZER CONFIGURATION

4.1 Selecting LANGUAGE to Operate Analyzer..........................................37

4.2 Configuring Sensors (A, B, C, and D):

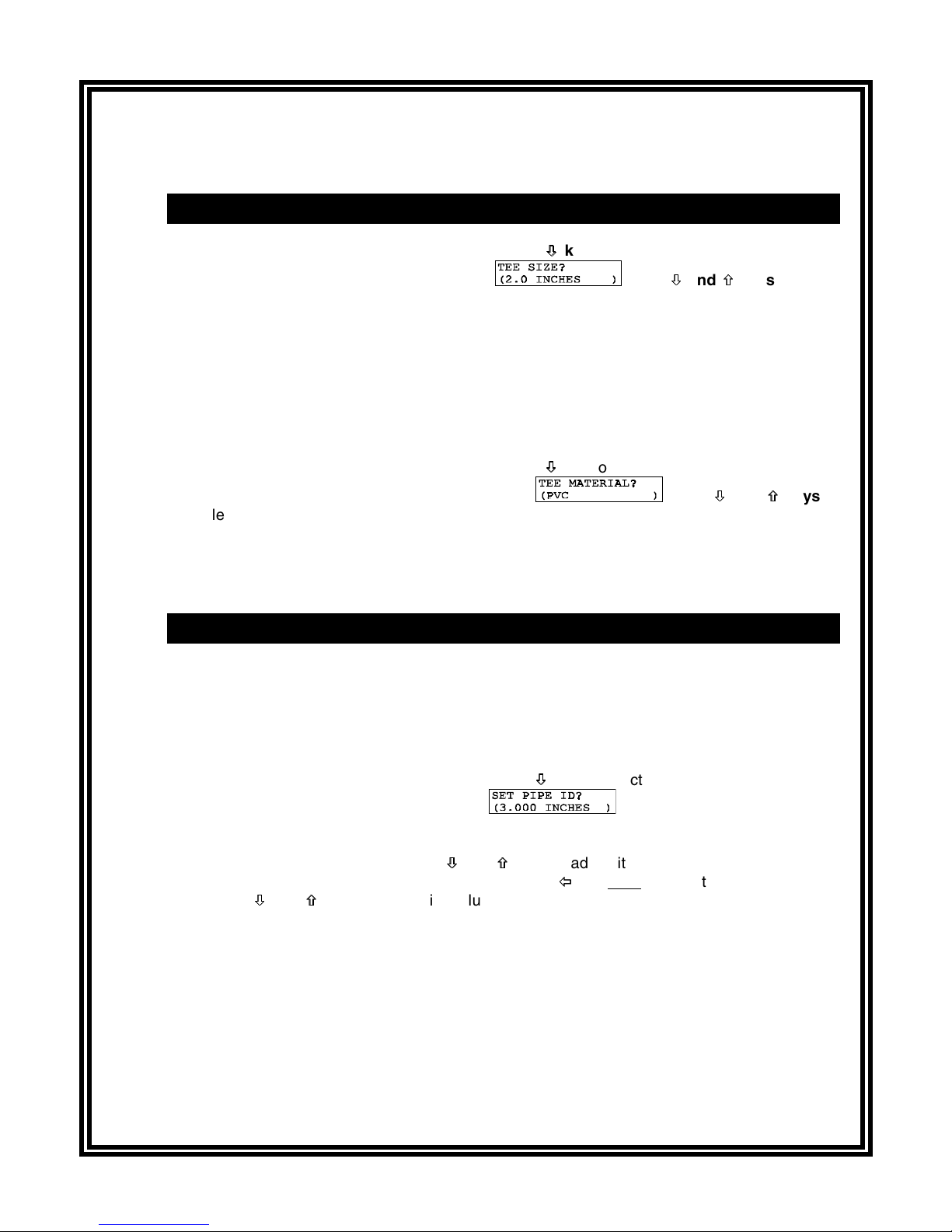

SET MULTIPLIER (for displayed flow rate).................................38-39

SET DECIMAL (for displayed flow rate)...........................................39

SET FILTER Time.......................................................................39-40

Select FLOW UNITS (for displayed flow rate) ............................40-41

Select VOLUME UNITS (for displayed volume)...............................41

Set LO FLOW CUTOFF Limit ..........................................................42

Select TOTALIZER MODE (auto or manual reset) .....................42-43

ENTER NOTE (top line of MEASURE screen).................................43

SELECT SENSOR Type .............................................................43-44

SET SENSOR Data:

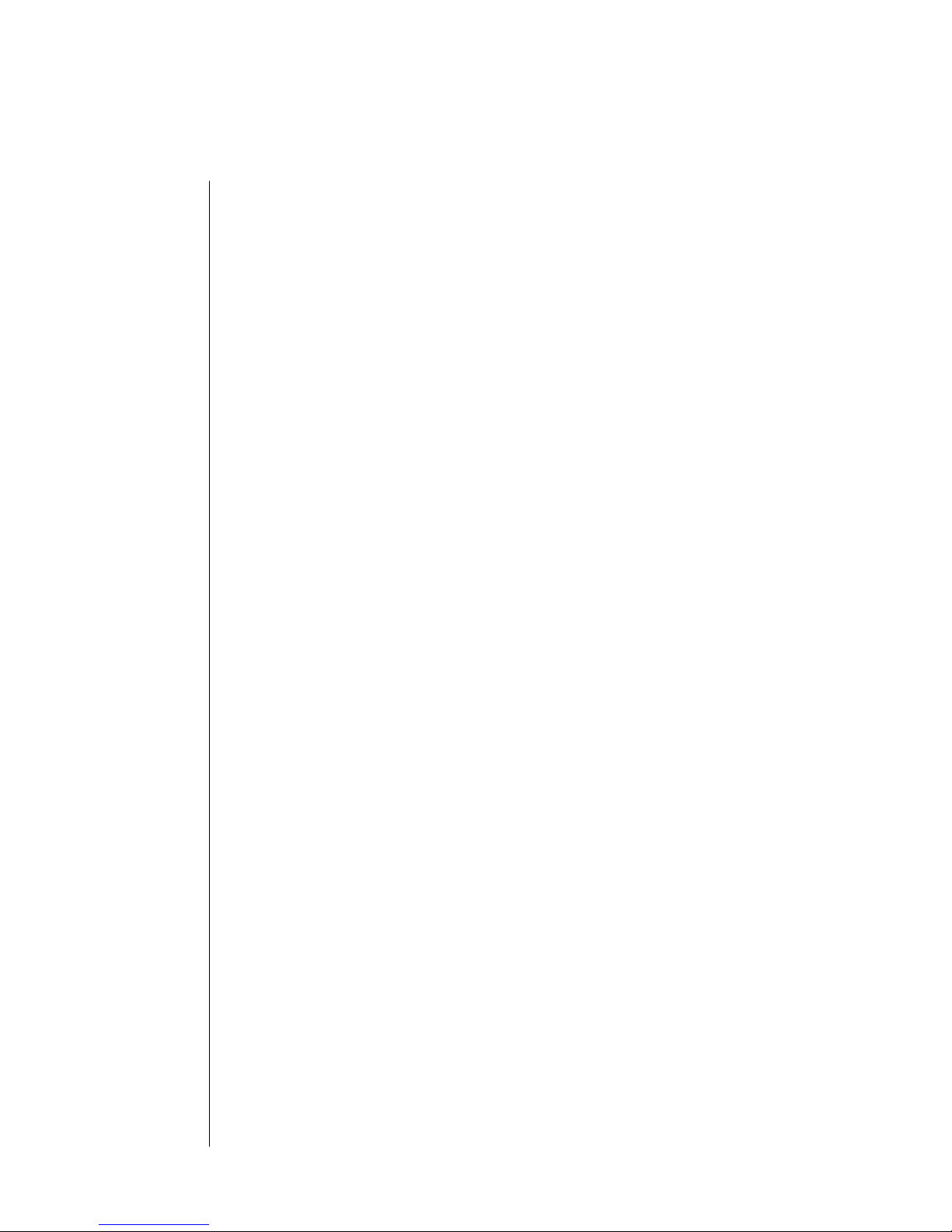

GLI Tee Mount -- Select TEE SIZE and TEE MATERIAL......44-45

GLI Pipe Mount -- SET PIPE ID..................................................46

Non-GLI Sensor -- SET SLOPE and SET OFFSET Values......47-48

4.3 Configuring CALCULATION Measurement:

SET VARIABLE X ............................................................................49

SET VARIABLE Y ............................................................................50

SET FORMULA (X/Y, X-Y, X+Y, or [X/Y] x 100) ..............................50

Select DISPLAY FORMAT (decimal and multiplier)....................51-52

4.4 Configuring Analog Outputs (1 and 2):

SET PARAMETER (representation) ...........................................53-54

SET 0/4 mA and 20 mA VALUES................................................54-55

SET FILTER Time............................................................................55

Select SCALE 0 mA/4 mA (low endpoint) ........................................55

4.5 Configuring Relays (A, B, C, and D):

SET PARAMETER (representation) ...........................................56-57

SET FUNCTION Mode (alarm, control or status).............................57

ACTIVATION (configuration values)...........................................58-59

4.6 Configuring Pulse Outputs (A and B):

SET PARAMETER (representation) ................................................60

SET VOLUME Increment ............................................................60-61

Set PULSE DURATION ...................................................................61

4.7 SET PASSCODE (feature enabled or disabled) ...................................62

4.8 Configuration Setting Summary (ranges/choices and defaults) .......63-65

SECTION 5 ANALYZER CALIBRATION

5.1 Important Information ............................................................................66

5.2 OFFSET BY or SET TO Calibration Adjustment ..............................67-68

5.3 Analog Outputs (1 and 2) Calibration...............................................68-69