GFE-S and GFE SH Detector

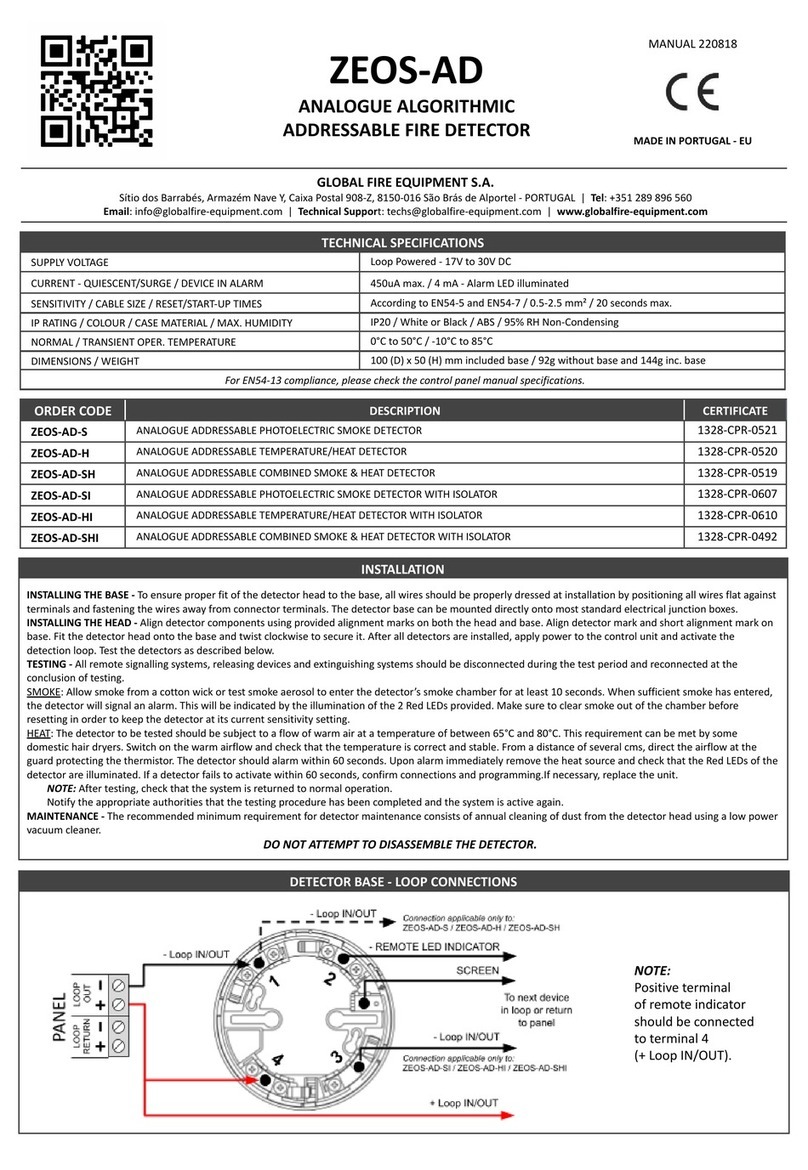

Installation Wiring Diagram

TYPICAL WIRING DIAGRAM

Figure 1(a) shows the typical wiring diagram of the

2-wire multiple-station smoke detector system.

INITIATING

LOOP

EN54 LISTED

COMPATIBLE

CONTROL

PANEL

+

-

FIRST DETECTOR BASE LAST DETECTOR BASE

RESISTOR

5

252

61 34 61 34

+-+

REMOTE

INDICATOR

CLASS A OPTIONAL WIRING

N

TE: IF REM

TE INDI

AT

R I

N

T

ED. P

LARITY T

DETE

T

R MAY BE REVER

ED.

-

Figure 1(b) shows the typical wiring diagram of the

4-wire multiple-station smoke detector system.

WARNING

TO PREVENT DETECTOR CONTAMINATION AND

SUBSEQUENT WARRANTY CANCELLATION, THE

SMOKE DETECTOR MUST REMAIN COVERED UNTIL

THE AREA IS CLEAN AND DUST FREE.

INSTALLING THE BASE

1. To insure proper installation of the detector head to the

base, all the wires should be properly addressed at

installation:

(A) Position all the wires flat against terminals.

(B) Fasten the wires away from connector terminals.

2. If you use a jumper wire to connect the poles of

terminal 2 and 5 when testing the detector loop

continuity, be sure to remove the jumper wire prior to

the installation of the detector head.

3. The end-of-line device shown in fig. 1(a) and 1(b)

should be compatible with the control unit. The

end-of-line supervisory relay used should be rated for

the DC power voltage used.

4. Open area smoke detectors are intended for mounting

on a ceiling or a wall in accordance with the fire

standard in your country.

5. The base of the smoke detector can be mounted

directly onto an electrical junction box such as an

octagonal (75mm, 90mm or 100mm), a round (75mm),

or a square (100mm) box without using any type of

mechanical adapter.

INSTALLING THE HEAD

1. Align the components as shown in Figure 2.

2. Mate the detector head onto the base and twist

clockwise to secure it.

3.Do not install the detector head until the area is

thoroughly cleaned of construction debris, dusts, etc.

The maximum number of smoke detector installed in

the same detection zone is typically 30 units. Refer to

control panel manual.

Fig. 2 Fitting detector head onto base

ADJUSTING THE RELAY FOR NO/NC

The normal condition for the relay is “normally open”

(NO).

1. To adjust the normal condition of the relay to

“normally closed”(NC), insert a screwdriver into the

rectangular hole located on the side between the front

cover and base and rotate to remove the front cover.

2. Refer to figure 3. There is a jumper head next to the

relay on the PCB. Remove the jumper head and reinsert

it in the NC position.

3. Carefully replace the front cover.

Relay contact rating:

1A@30VDC,

0.5A@125VAC.

TESTING

1. All remote signaling systems, releasing devices and

extinguishing systems should be disconnected

during the test period and reconnected at the

conclusion of testing.

2. After energizing the detector head for approximately

one minute, check to see the indicator green LED

flashing once every 3~5 seconds. If green LED fails to

flash, it indicates the non-functioning of the detector or

faulty wiring. Re-check the wiring or replace the

detector if necessary.

3. Allow smoke from a cotton wick or a test smoke

aerosol to enter the detector-sensing chamber for at

least 10 seconds. When sufficient smoke has entered

the chamber, the detector will signal an alarm, this

being visible by a continuous illumination of the LED.

Reset each detector and/or control unit before

attempting to test any additional detectors in the same

zone. If the alarm fails in this step, it indicates a

defective unit, which requires service.

Fig. 3 Schematic of detector structure

When front cover is open.