3

FOREWORD

As a lift truck operator, you are respon-

sible for a machine that is useful, pow-

erful, and can be hazardous if not

operated as described. Your Global

Industrial truck may weigh more than

some cars, depending on the model.

Observing and practicing the safety

warnings in this manual cannot be over-

emphasized. Just knowing the warn-

ings, however, is no substitute for

common sense. Focusing on the task

at hand, in almost all cases, prevent

accidents. Think of the truck as your

own. In this way you will learn its capa-

bilities and limitations.

This manual is intended to remain with

the truck at all times as a handy refer-

ence guide to operation. Detailed main-

tenance procedures are found in the

parts and service manual for the spe-

cific truck model, and are to be per-

formed only by a qualified technician.

For further information on obtaining a

c o m p l e t e p a r t s a n d s e r v i c e m a n u a l , s e e

page 26 of this manual.

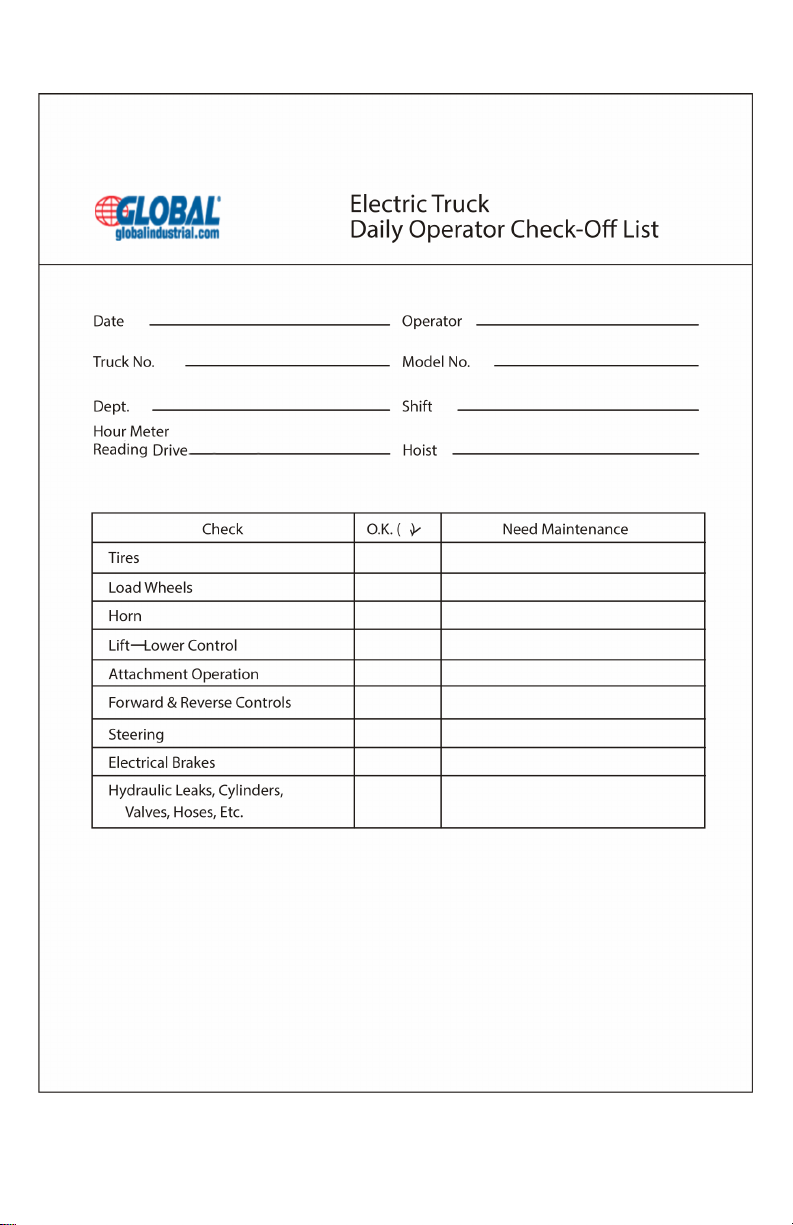

The operator who knows his truck will

learn to spot problems as they develop.

This is accomplished by performing the

Daily Checks and reporting any prob-

lems to the designated authority.

TABLE OF CONTENTS

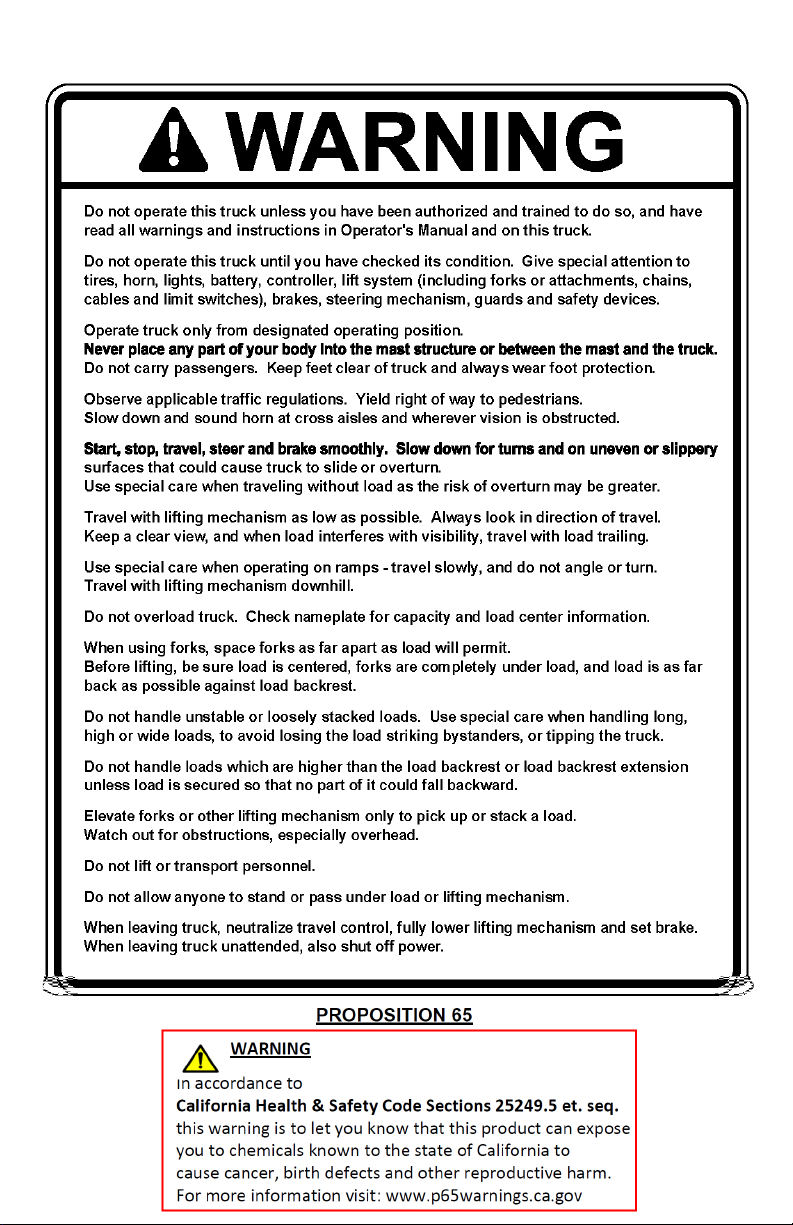

SAFETY SYMBOLS ..............................................................................................4

GENERAL DESCRIPTION ....................................................................................4

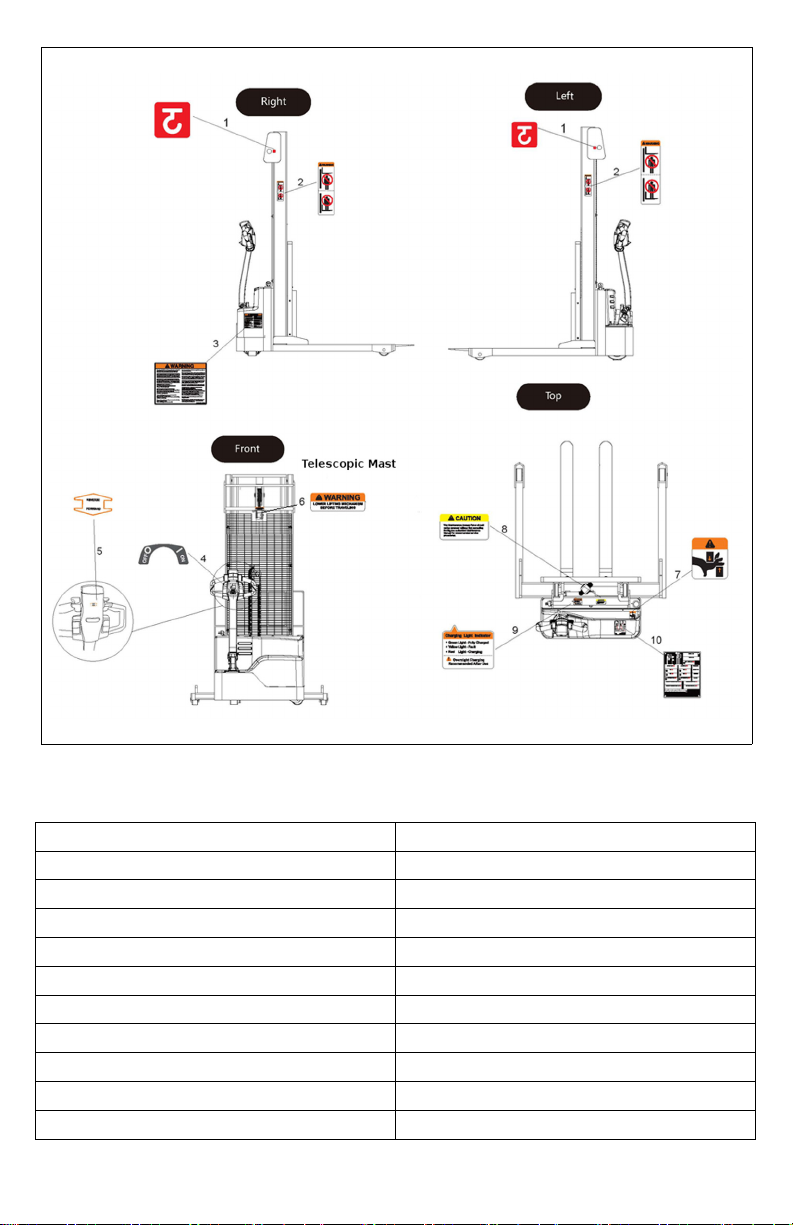

NAME PLATE AND WARNING DECAL ...............................................................4

LOAD CAPACITY..................................................................................................6

BEFORE OPERATION ..........................................................................................7

INSTRUMENTS AND CONTROLS .....................................................................10

OPERATION ........................................................................................................11

OPERATION ........................................................................................................11

Forward and Reverse Travel and Speed Control ...............................11

Steering ..................................................................................................11

Stopping.................................................................................................12

Parking ...................................................................................................12

Battery Charging ...................................................................................13

Load Handling .......................................................................................13

Moving a Disabled Truck ......................................................................14

NOTICE - OBTAINING A PARTS AND SERVICE MANUAL..............................26