Global Power Technologies IMPORTANT SAFETY INSTRUCTIONS

302672 Rev2 | MX PrimeGen 2

2IMPORTANT SAFETY INSTRUCTIONS

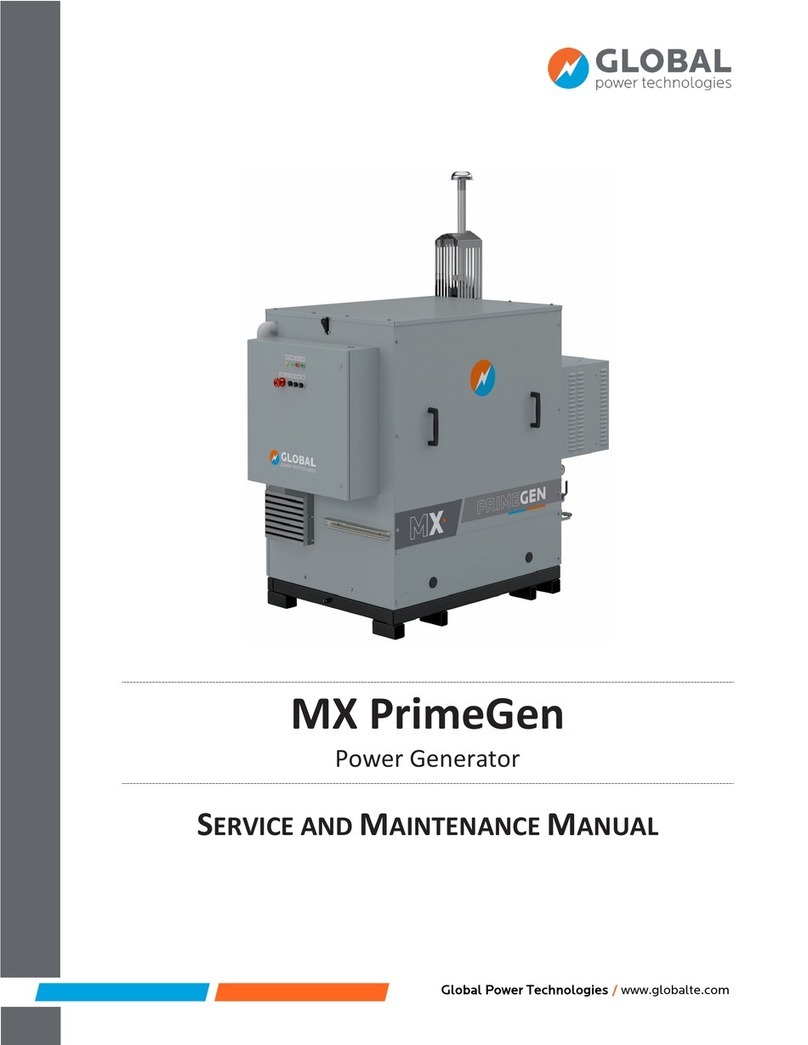

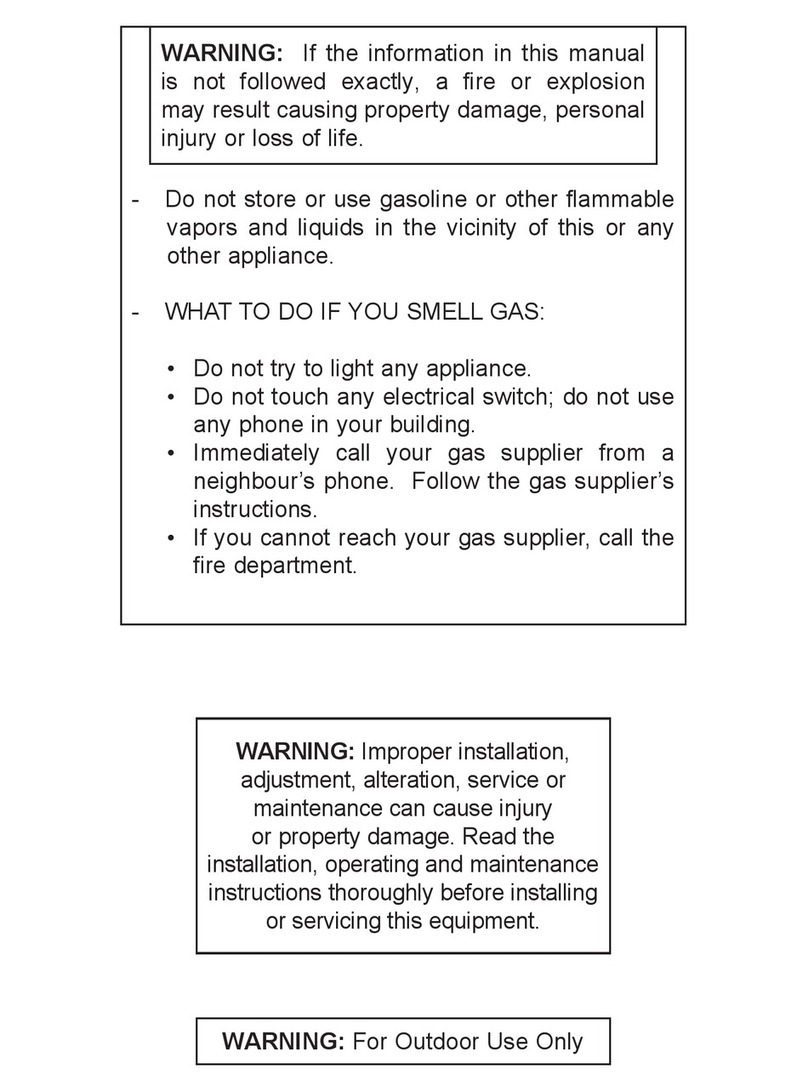

SAVE THESE INSTRUCTIONS – This manual contains important instructions for the MX PrimeGen Power

Generator that should be followed during installation and maintenance of the generator and its

batteries. Read the following safety warnings before beginning assembly, installation, or maintenance

of the MX Power Generator.

1. Observe all prescribed accident prevention and safety rules. Do not perform work on the MX Power

Generator alone—make sure there is somebody else working with you.

2. The installation of the MX Power Generator must conform with local codes or, in the absence of

local codes, with CSA-B149.1 – Natural Gas and Propane Installation Code.

3. When installed, the MX Power Generator must be electrically grounded in accordance with local

codes, or in the absence of local codes, with CSA C22.1 – Canadian Electrical Code.

4. The MX Power Generator is not intended to be used in underground mines. Do not use the MX

system in underground mines.

5. Per local codes, the MX Power Generator shall be installed with a fuel shut-off valve. This is not

included in the base design but is included with the regulator option added. The shut-off valve must

be disconnected from the gas supply piping system during any pressure testing of that system at

test pressures more than 34 kPa (5 psi).

6. The MX Power Generator must be isolated from the gas supply piping system by closing its

individual manual shut-off valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 34 kPa (5 psi).

7. Do not use the MX Power Generator if any part has been under water. Immediately call a qualified

service technician to inspect and to replace any part of the control system, gas control and

generator that has been under water.

8. The MX Power Generator is designed to combust gaseous fuels which will result in combustion

products of heat, carbon dioxide and water vapour. It may contain traces of carbon monoxide,

unburnt hydrocarbons, and nitrous oxides. Emissions from combustion will depend on generator

set-up and operation as well as the composition of the gas feed. It is imperative that these

instructions be followed, and that gas supplied meets the gas specifications outlined in this manual.

9. The MX Power Generator must be mechanically installed according to the instructions contained

within this manual. It must be securely anchored to a non-combustible surface when installed.

10. Installation and repair must be performed by a qualified service person. The MX Power Generator

should be inspected before use and at least annually by a qualified service person. More frequent

cleaning may be required as necessary. It is imperative that control compartment, air intakes, and

circulating air passageways of the system are kept clean.

11. The MX Power Generator uses an internal combustion engine. Qualified service personnel should

have mechanical knowledge on how to maintain engine fuel, lubrication, ignition, and cooling

systems.

12. The MX Power Generator contains electrical, and gas related safety devices as identified

throughout this manual. Tampering or rendering inoperative any of these safety devices may result

in personal injury or death and possible damage to the equipment and is not permitted under any

circumstances.