Global Power Technologies 2

S-8500

1.2 GENERAL INFORMATION

This manual provides instructions for the installation, operation, performance, basic

maintenance and troubleshooting of the model S-8500 Thermoelectric Generator (TEG),

a device that produces electrical power through the direct conversion of heat energy to

electrical energy.

Appendices provide reference details for the Technical Specifications, Wiring diagrams and

electrical schematics, Parts lists and Options.

WARNINGS and CAUTIONS are important to understanding any limitations of the device

placed on its installation and operation in a safe manner as is intended by the design.

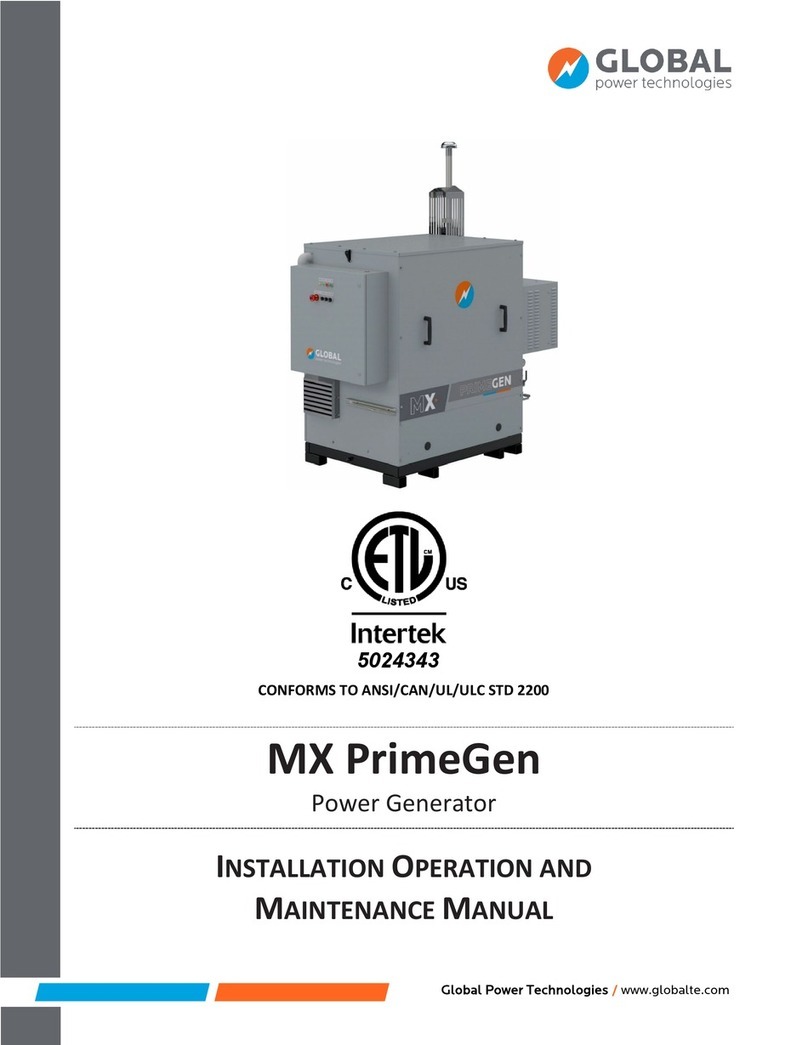

The model S-8500 TEG has been independently tested by Intertek and certified to CSA

T.I.L.-R10 Thermoelectric Generators and is authorised to carry the ETL mark.

WARNING Do not use this Thermoelectric Generator if any part has been under

water. Immediately call a qualified service technician to inspect the appli-

ance and to replace any part of the control system and any gas control

which has been under water.

WARNING: The Thermoelectric Generator must be mechanically installed according

to the instructions contained within this manual. The Generator has a

mass of 273KG (603 lbs), a high center of gravity, and a low tipping angle

of 11 degrees from vertical. The Generator must be securely bolted to a

mounting pad or platform when assembled. See Appendix B.

WARNING: Inspect and check all gas connections for leaks using a commercially

available liquid leak detection fluid after installation or service to any part

of the fuel system. Remedy any fuel system leaks prior to starting the

Thermoelectric Generator.

WARNING: This device contains electrical and gas related safety devices as identi-

fied throughout this manual. Tampering or rendering inoperative any of

these safety devices may result in personal injury or death and possible

damage to the equipment and is not permitted under any circumstances.

WARNING: The Thermoelectric Generator is designed to combust gaseous fuels

which will result in combustion products of heat, carbon dioxide and

water vapor and may contain traces of Carbon Monoxide, unburnt

Hydrocarbons and Nitrous Oxides. Emissions from combustion will

depend on generator set-up and operation as well as the composition of

the gas feed. It is imperative that these instructions be followed and that

gas supplied meets Global Power Technologies’ gas specification.

CAUTION: The Thermoelectric Generator consists of some parts constructed

from sheet metal. Every effort is made to ensure that edges have been

deburred when manufactured, sharp edges may still exist . Caution must

be exercised when handling and use of (gloves) is advised.