CONTENT

Equipment Introduction..................................................................................................1

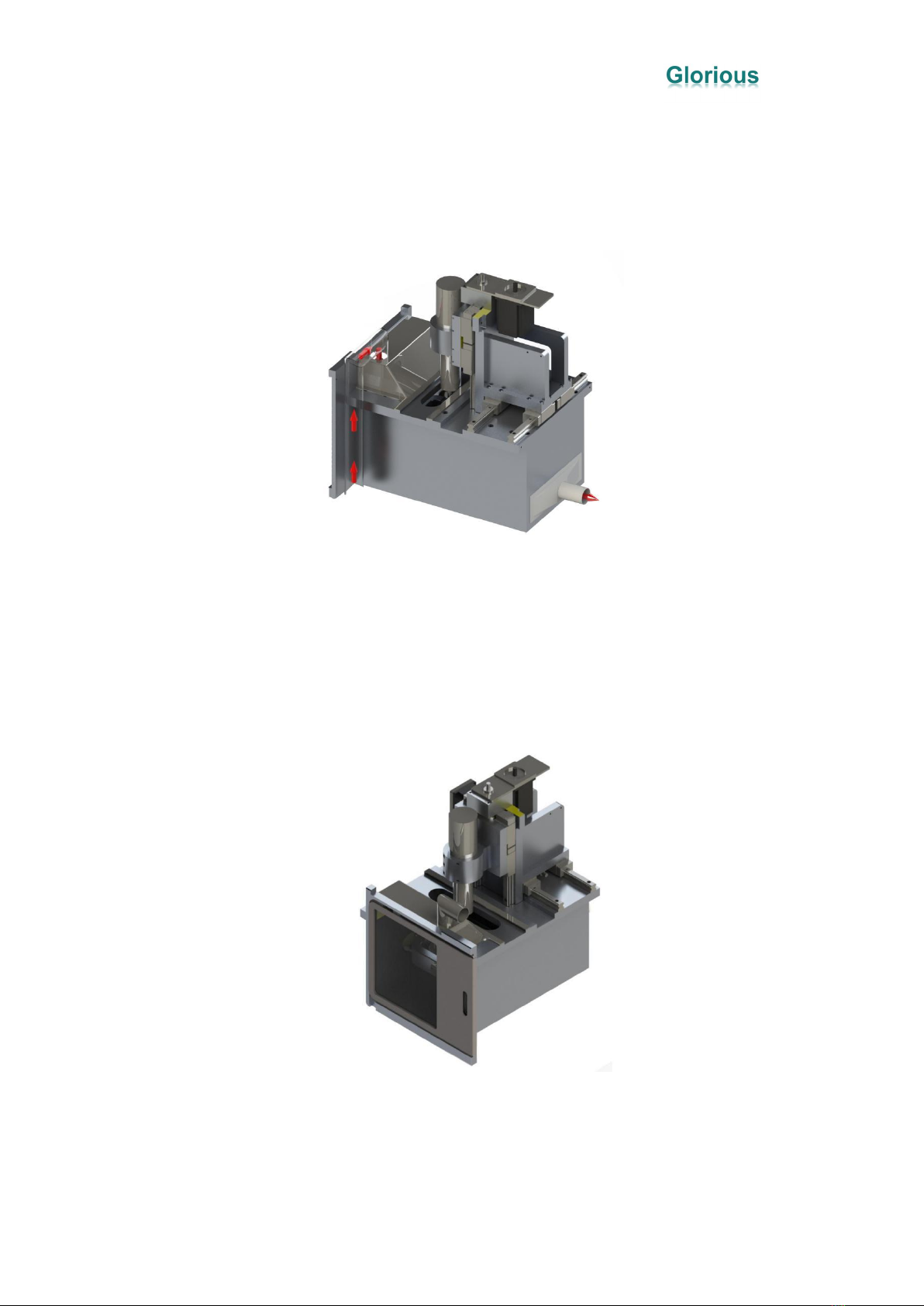

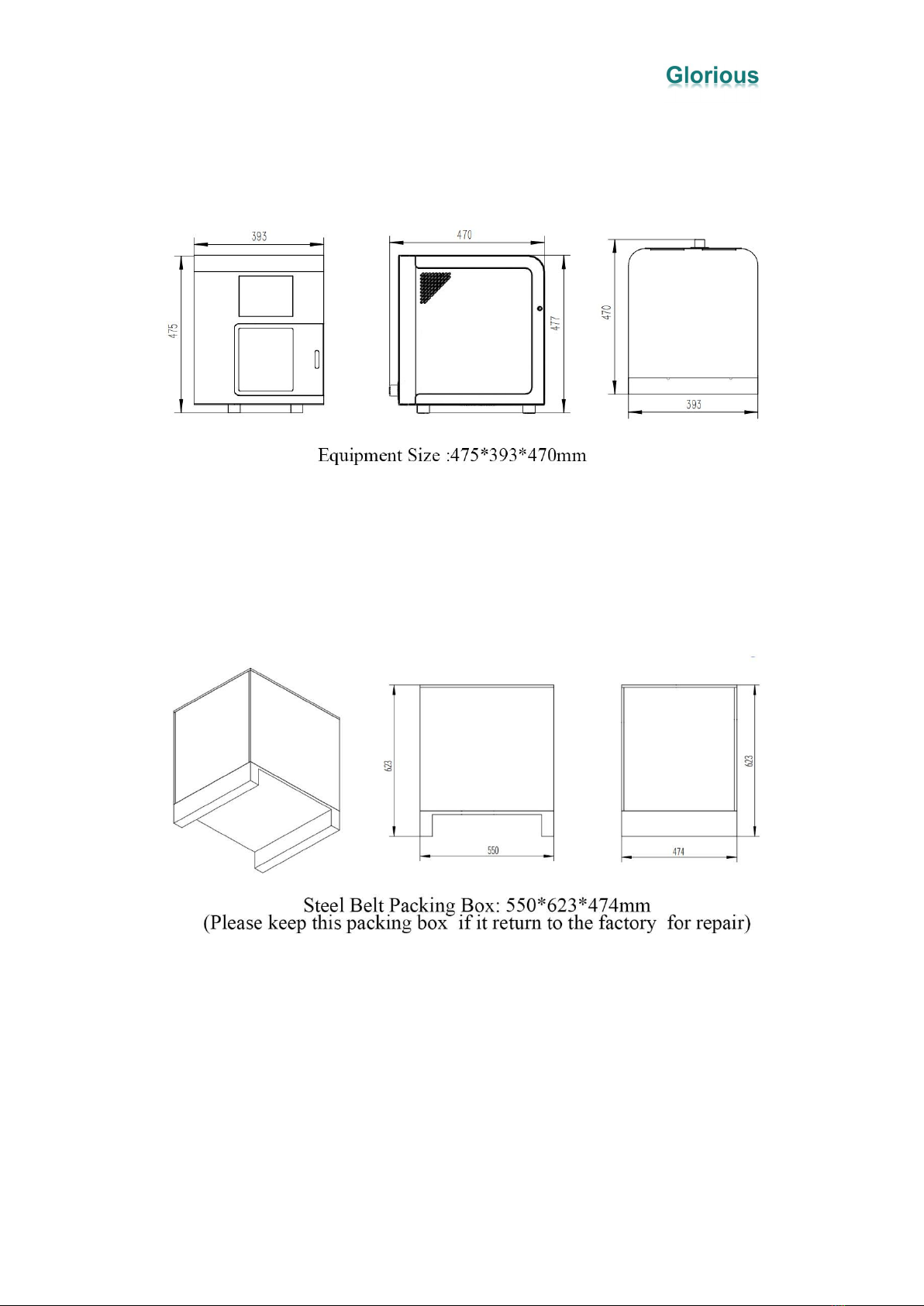

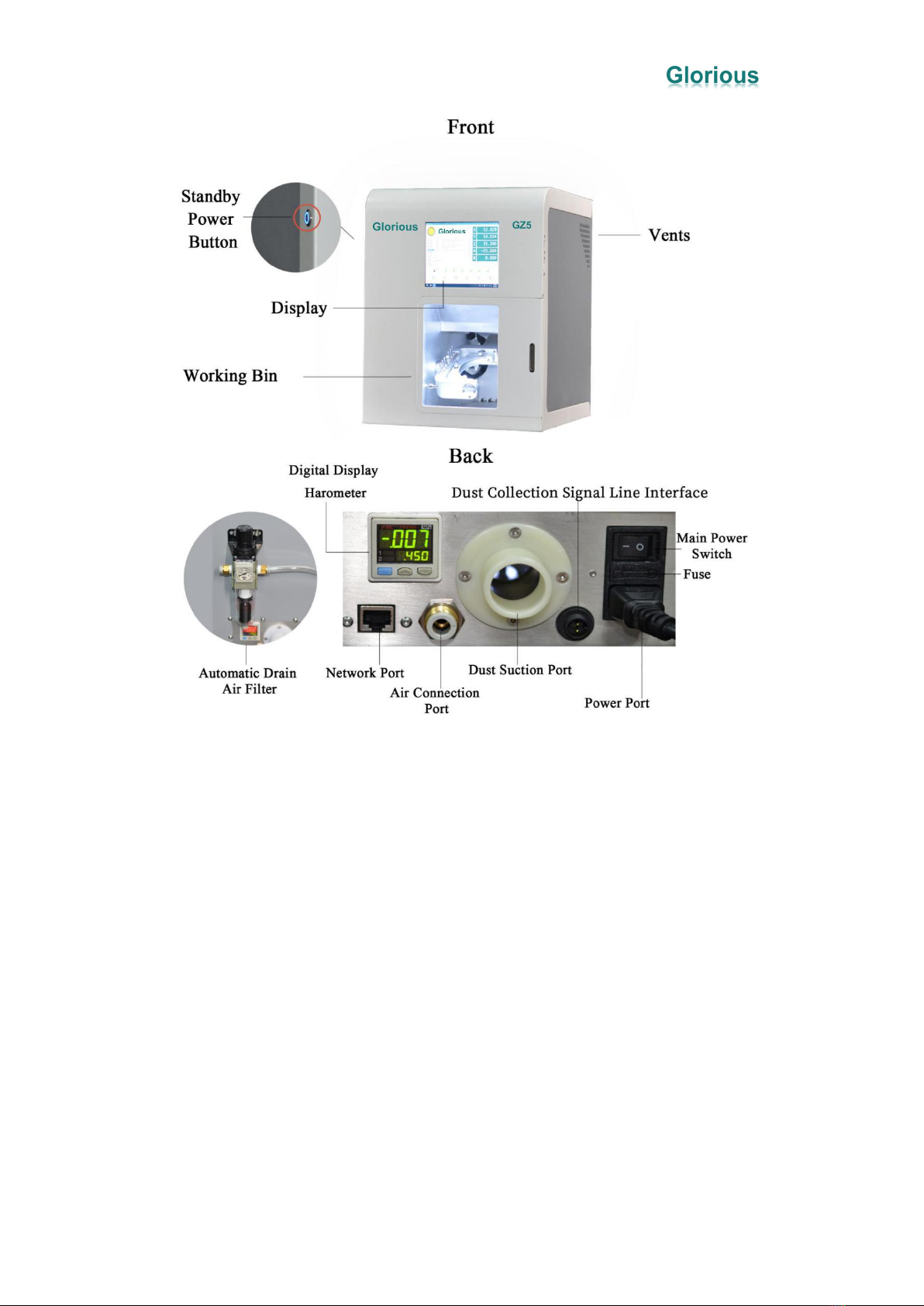

1.1 Equipment Destription................................................................................... 1

1.2 Equipment Features........................................................................................1

1.3 Equipment Parameters....................................................................................4

Installation Environment................................................................................................ 5

2.1 GZ5`s Installation Environment and Conditions........................................... 5

Equipment Accessories and Installation.........................................................................6

3.1 Whiteth GZ5 Accessories List........................................................................6

3.2 Installation guide of GZ5............................................................................... 6

Equipment Operation Guidance..................................................................................... 9

4.1 How To Use....................................................................................................9

4.2 Precautions..................................................................................................... 9

4.3 Solution After An Alarm Occurs.................................................................. 10

4.4 Material Saving Mode Fixture Adjustment Method.................................... 12

4.5 CERCON Φ105mm Large Size Fixture Adjustment Method...................... 12

4.6 Accuracy Calibration Method...................................................................... 13

4.7 GZ5 Typesetting Software Post-Processing (Only for reference by CAM

software application engineers).............................................................................16

4.8 Tool size........................................................................................................18