GB

5

b. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool

or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

e. Always unplug your power tool when leaving

unattended. Such preventative safety measures

reduce the risk of starting the power tool accidentally

by untrained users.

f. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power tools

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

g. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

h. Use the power tool, accessories and tool bits etc.,

in accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions and

the work to be performed. Use of the power tool for

operations different from those intended could result in

a hazardous situation.

5. SERVICE

a. Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

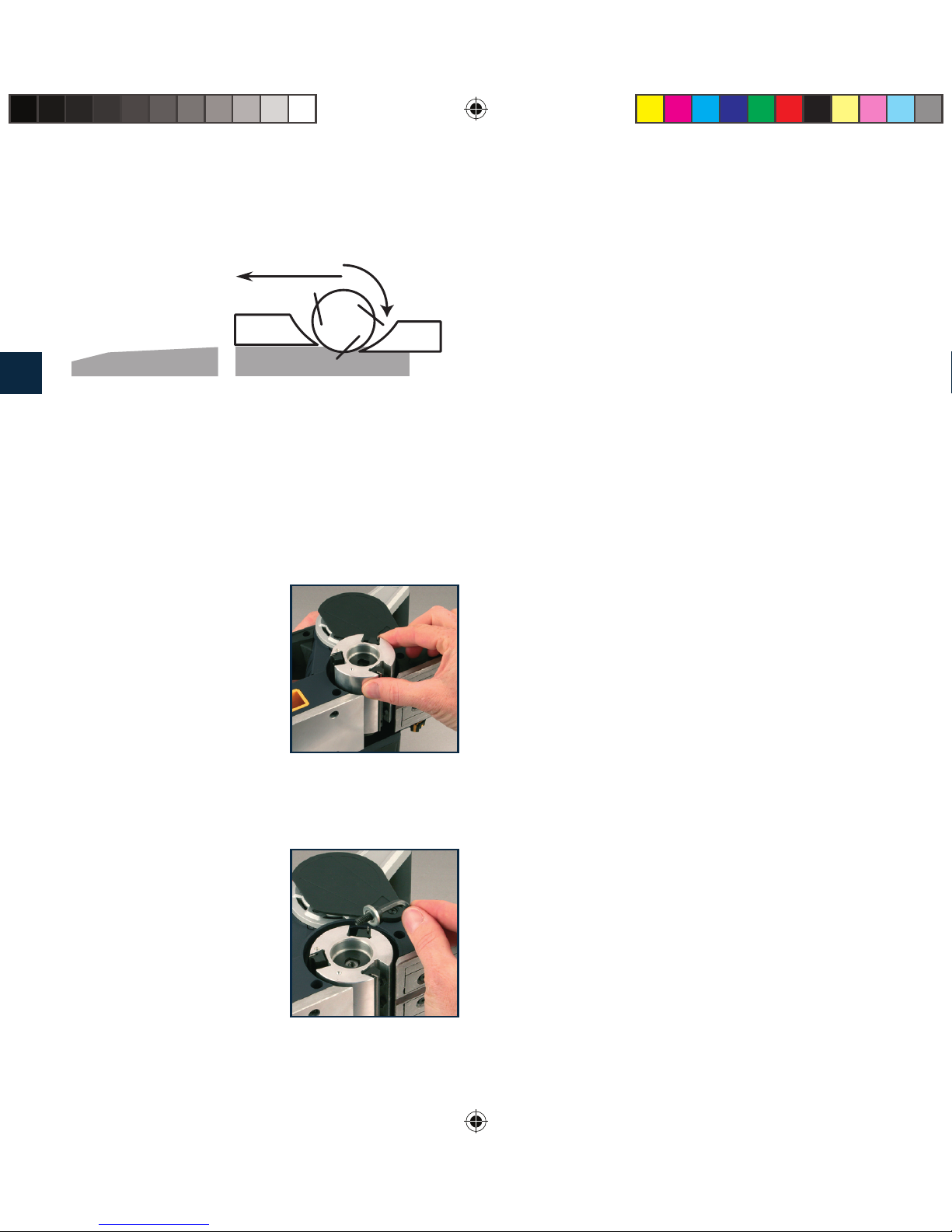

Additional safety rules for electric planers

• Wait for the cutter to stop before setting the tool down.

An exposed cutter may engage the surface leading to

possible loss of control and serious injury.

• Fully unwind cable drum extensions to avoid

potential overheating.

• When an extension cable is required, you must ensure

that it has the right ampere rating for your power tool and

is in safe electrical condition.

• Ensure your mains supply voltage is the same as your

tool rating plate voltage.

• After long working periods, external metal parts and

accessories could be hot.

• If possible, always use clamps or a vice to hold your work.

• Always switch off before you put the planer down.

• Do not force the planer: let the tool do the work at

a reasonable speed. Overloading will occur if too

much pressure is applied and the motor slows resulting

in inefficient planing and possible damage to the

planer motor.

• Always use a dust extraction system where possible.

• Rags, cloths, cord, string and the like should never be

left around the work area.

• Remove all nails, screws and other objects from the

workpiece. You can damage the blade and the tool by

cutting into a nail or other foreign object. It can also

present a safety hazard.

• Handle the blades very carefully.

• Be sure that the blade installation bolts are securely

tightened before operation.

• Always wear eye and ear protection and use a

dust mask.

• Hold the tool firmly with both hands.

• Keep hands away from rotating parts.

• Before using the tool on an actual workpiece, switch

on and let it run for a while. Watch for vibration or

wobbling that could indicate poor installation or a

poorly balanced blade.

• Make sure that a blade is not in contact with the

workpiece when you switch the machine on.