2 5700 - SIL 3 HART®Multiplexer Modem G.M. International ISM0366-2

General Description:

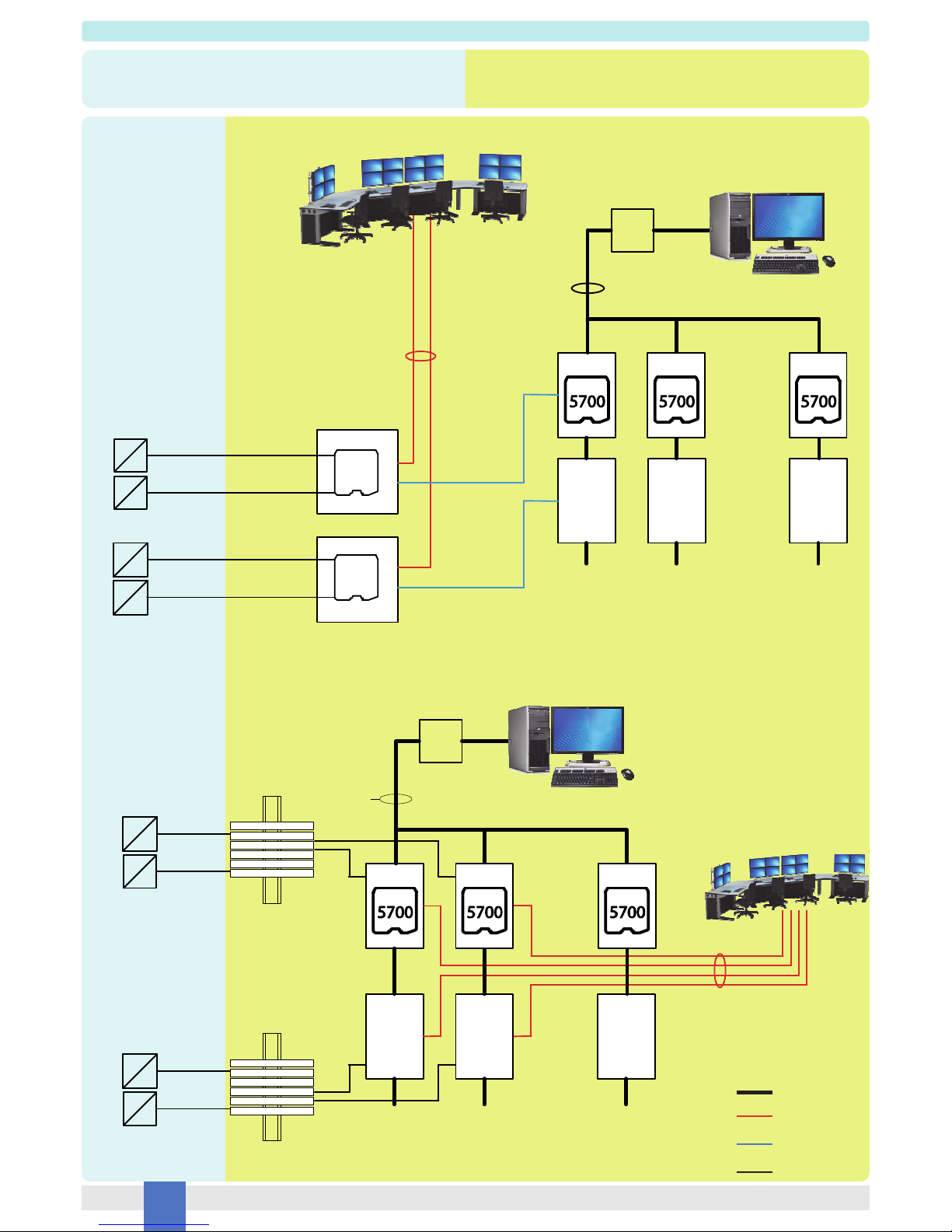

The HART® Multiplexer Modem 5700 interfaces up to 256 smart devices (transmitters, I/P, proportional valves, etc…) in a HART® Network. Each device can be fully identified,

configured and monitored by a remote PC running an FDT-based software package (PACTware™, etc...) through a dedicated Device Type Manager (DTM).

Up to 63 Multiplexer Modem 5700 (16128 loops) can be connected in multi-drop mode to the PC through the RS485 HART® Protocol, whose baudrate can be configured via software.

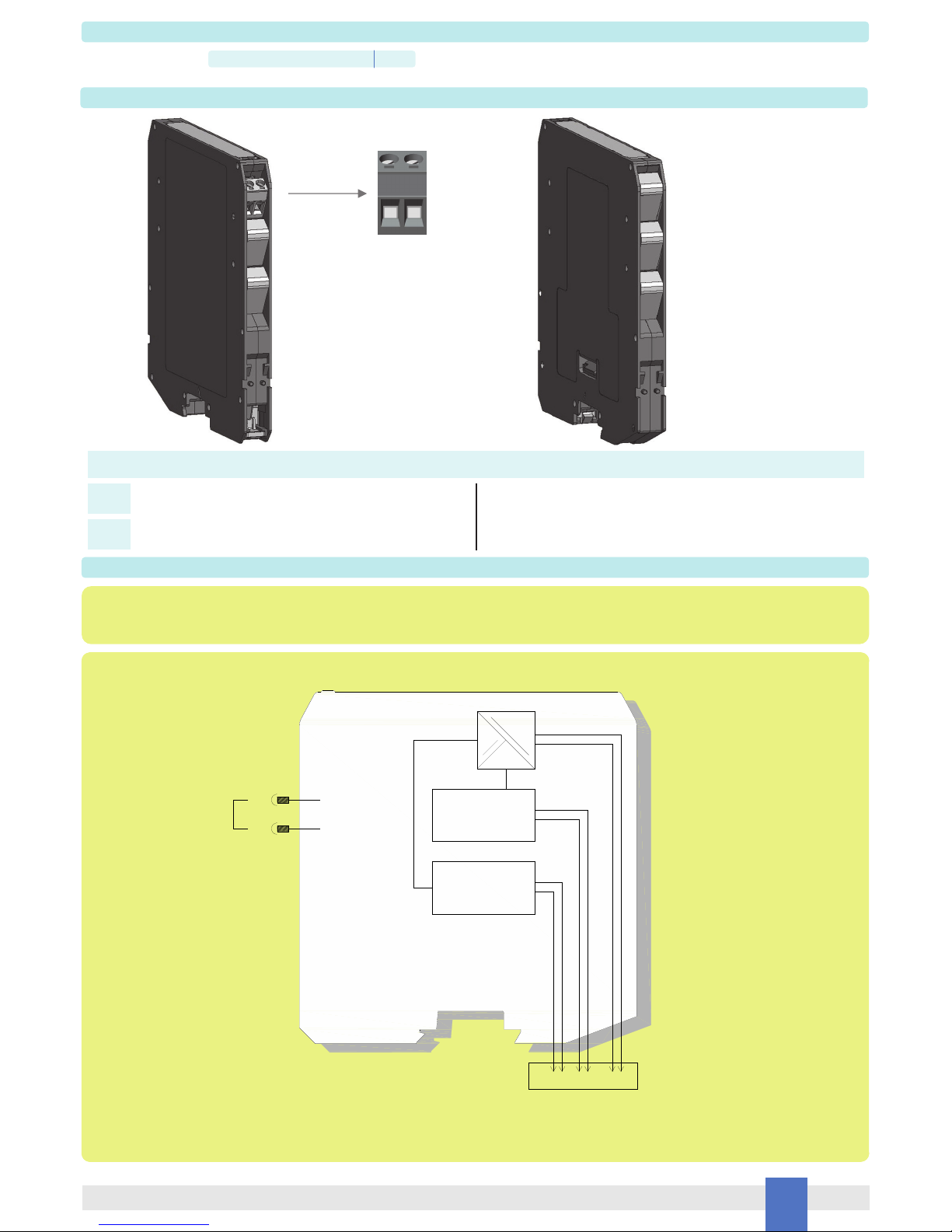

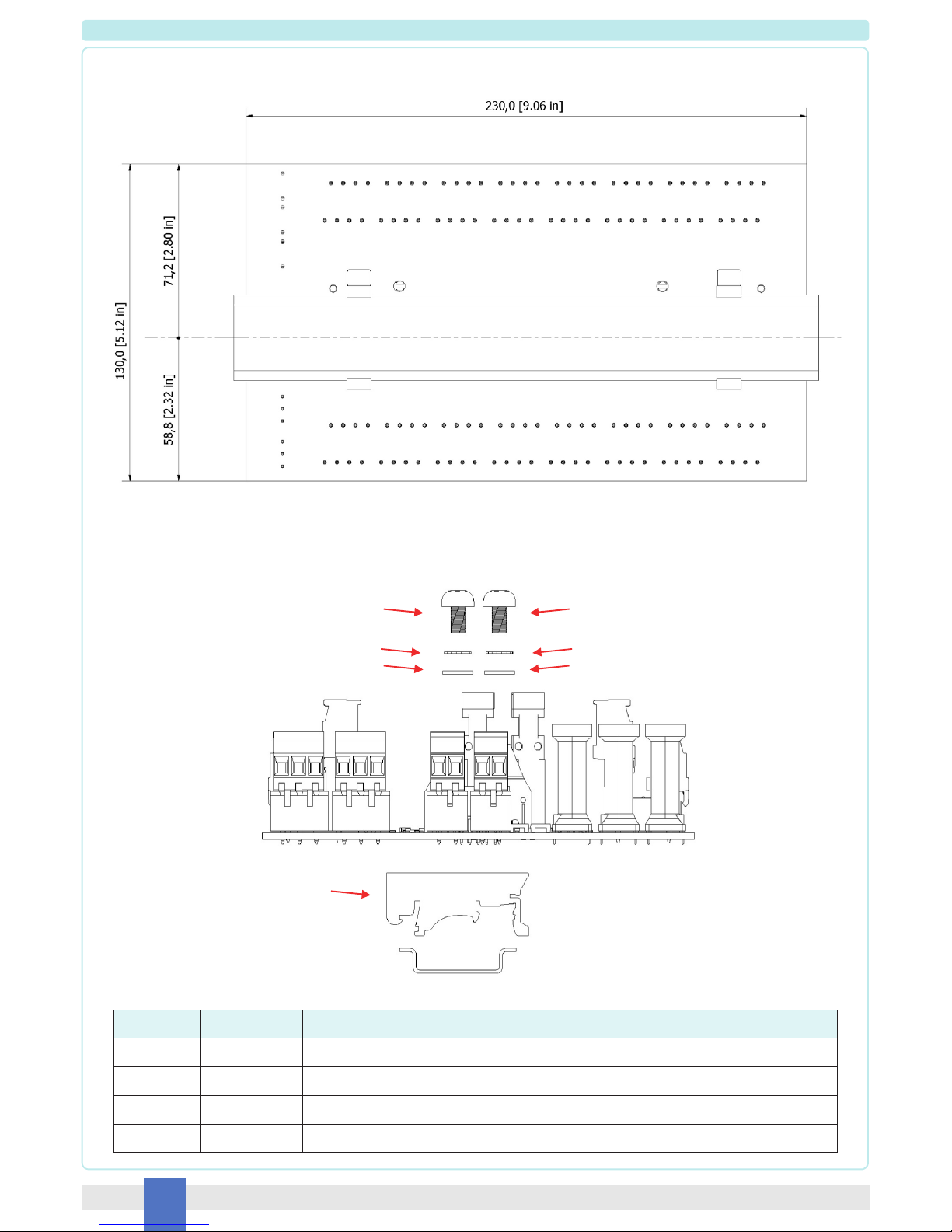

The module is intended to be mounted on the following Termination Boards:

TB-D5001-HRT-003: to be used with G.M. International AI/AO Termination Boards;

TB-D5001-HRT-004: to be used with DIN-Rail mounted barriers/isolators or direct field connections, for 4-20mA loop signal;

TB-D5001-HRT-005: to be used with DIN-Rail mounted barriers/isolators or direct field connections, for 1-5V loop signal.

Termination board types can be combined to manage different interfaces at the same time, simply respecting maximum number of connected channels.

The HART® Multiplexer Modem 5700 is SIL 3 certified as non-interfering with the signal loops.

The module guarantees three-port (supply/interface/channels) isolation.

Functional Safety Management Certification:

G.M. International is certified by TUV to conform to IEC61508:2010 part 1 clauses 5-6 for safety related systems up to and included SIL3.

Technical Data

Characteristics

Supply:

24 Vdc nom (18 to 30 Vdc) reverse polarity protected, via Termination Board.

Current consumption @ 24 V: 40 mA typical (in full topology configuration).

Power dissipation: 0.5 W @ 24 V typical (modem only), 1 W @ 24 V typical (in full topology configuration).

Isolation (Test Voltage):

Interface/Power Supply: 500 Vrms.

Interface/Field channels: 500 Vrms.

Power Supply/ Field channels: 500 Vrms.

Input:

Number of channels: 256.

HART®field device Input: revision 5 to 7.

Interface:

Baudrate: from 1200 to 115200 bps, software configurable.

Address: 0 - 62, software configurable.

Type: RS-485 differential pair and grounding.

Topology: multi-drop, master/slave connection.

Compatibility:

CE mark compliant, conforms to Directives:

2014/34/EU ATEX, 2014/30/EU EMC, 2014/35/EU LVD, 2011/65/EU RoHS.

Environmental conditions:

Operating: temperature limits – 40 to + 70 °C, relative humidity 95 %, up to 55 °C.

Storage: temperature limits – 45 to + 80 °C.

Safety Description:

ATEX: II 3G Ex nA IIC T4 Gc

IECEx : II 3G Ex nA IIC T4 Gc

non-sparking electrical equipment.

Approvals:

ATEX conforms to EN60079-0, EN60079-15 (pending).

IECEx conforms to IEC60079-0, IEC60079-15 (pending).

SIL 3 conforms to IEC61508:2010 Ed. 2 (pending).

TÜV Certificate No. C-IS-236198-09, SIL 3 Functional Safety Certificate conforms to IEC61508:2010 Ed.2, for Management of Functional Safety.

Mounting:

on customized Termination Board.

Weight: about 100 g.

Location: installation in Safe Area or Zone 2, Group IIC T4.

Protection class: IP 20.

Dimensions: Width 12.5 mm, Depth 123 mm, Height 120 mm.

Front Panel and Features

SIL 3 according to IEC 61508:2010 Ed. 2.

Systematic capability SIL 3.

Input from Zone 2, installation in Zone 2.

High Density, 256 Input channels.

HART® field device input, revision 5 to 7.

Three port isolation, Supply/Interface/Channels.

EMC Compatibility to EN61000-6-2, EN61000-6-4, EN61326-1 for safety system.

ATEX, IECEx, TÜV Certifications (pending).

TÜV Functional Safety Certification.

Simplified installation using standard customized Termination Boards.

RS-485 Interface.

FSM

SIL 3

7 8

5700

SIL 3

CONFIG

POWER

COMM.

OPER.