3

GENERAL INFORMATION

& SPECS

Tank:

All tanks are constructed from UV resistant

polyethylene� Polyethylene tanks have a very

high chemical resistance�

Due to the rotomoulding process, there can

be a variance in the overall dimensions of

the tank which in turn results in variations

to the tank capacity� For this reason, any

calibration markings should be used as a

guide only�

Filtration:

Filtration is a critical part of the sprayer’s

performance�

ATV200, 300 & UV400 are fitted with an

inline suction strainer� It is important that

the strainer is cleaned out regularly�

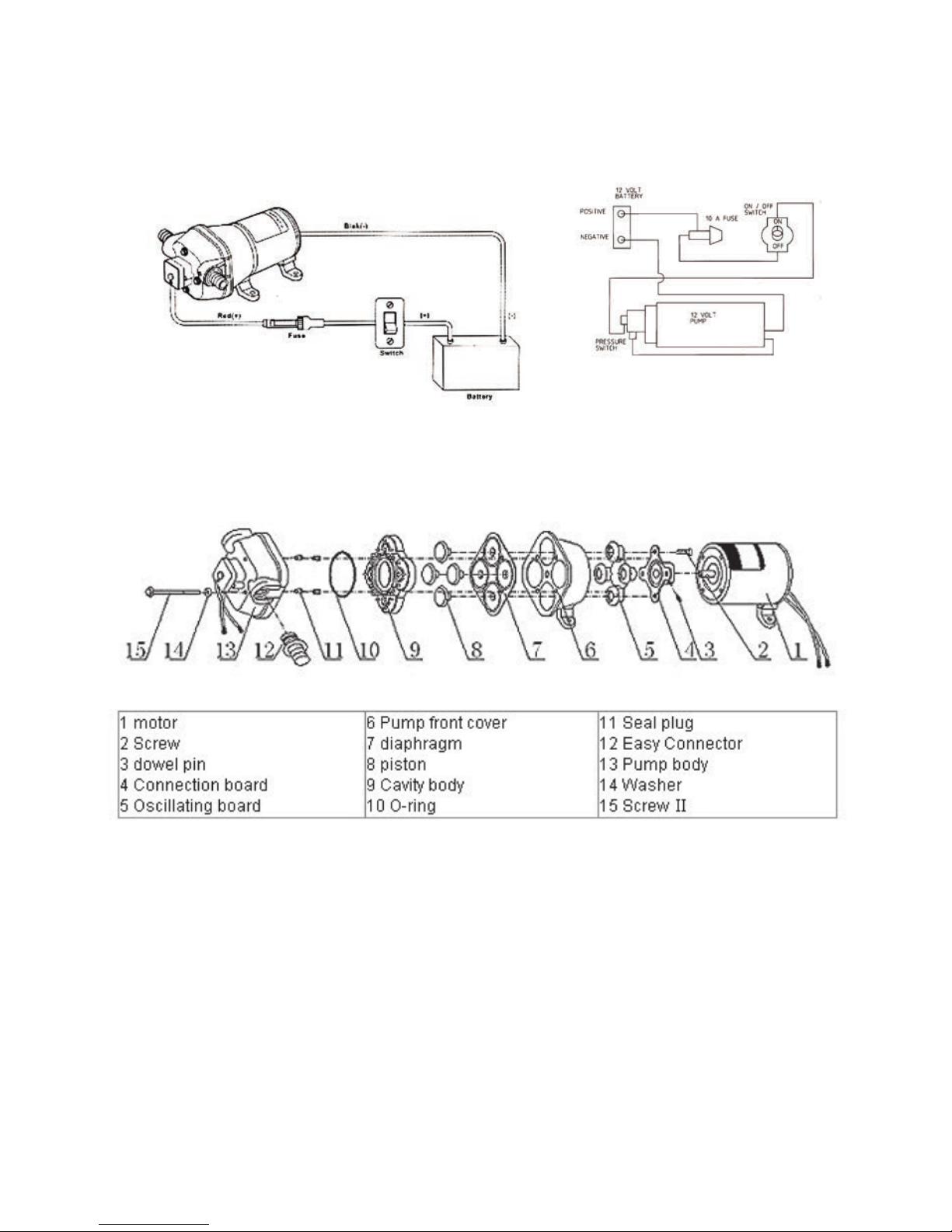

Pump:

The pump is critical to any sprayer

performance� Correct operation and

maintenance of the pump will ensure

the sprayer is able to perform to its

capabilities� Make sure the pump wires are

connected up to the correct terminals (red

to positive, black to negative)�

Always flush pump with clean water after

every use� Prolonged chemical contact can

severely damage valves, diaphragms and

seals�

Do not leave water in pump if sprayer is

to be left in a cold environment� The water

may freeze and cause damage to pump�

Empty pump of all water and cover the

pump to ensure this situation does not

arise� If this has not been done, and there

is a possibility there may be frozen water

in the pump, wait until any ice has thawed

before using the pump�

The 12 volt pumps are positive

displacement diaphragm pumps which

provide delivery upon demand�

They are self-priming and some models are

fitted with a pressure switch which senses

the outlet pressure of the pump� The

pressure switch turns the electrical power

off to the pump at a pre-determined high

pressure point�

As the outlet side of the pump is opened,

the pressure starts to drop and at a pre-

determined point (typically 40-75 psi)

contacts in the switch will lose causing the

pump to start automatically� The pump will

then pump until the pressure reaches the

shut-off pressure point�

CAUTION:

Do not adjust the pressure switch out so

that the pumping pressure exceeds the

maximum pressure for the pump�

If the flow demand is very low, the pump

may reach this high pressure point and

cause “cycling” (pump turns on and off

rapidly)�

This is not a problem unless the pump is

subject to continuous cycling within two

second intervals for long periods of time�

Altering the setting of the pressure switch,

or adjusting the agitation ball valve so that

there is some bypass back to the tank and

altering the adjustable conejet nozzle on

the gunjet will all remedy this situation,

depending on what is most suitable�

Chemical Induction:

Chemical should be put into the main tank

through the main tank lid� It is important to

ensure that chemical is thoroughly mixed

prior to spray application�

Nozzles:

As information regarding nozzles is specific

to those being used in your application,

no specific reference is made to nozzle

application rates or nozzle types in this

operator’s manual� Goldacres suggest the

use of a current nozzle selection catalogue

for reference to nozzle sizes, outputs, spray

patterns and general spraying information�

Goldacres recommends Lechler nozzles�