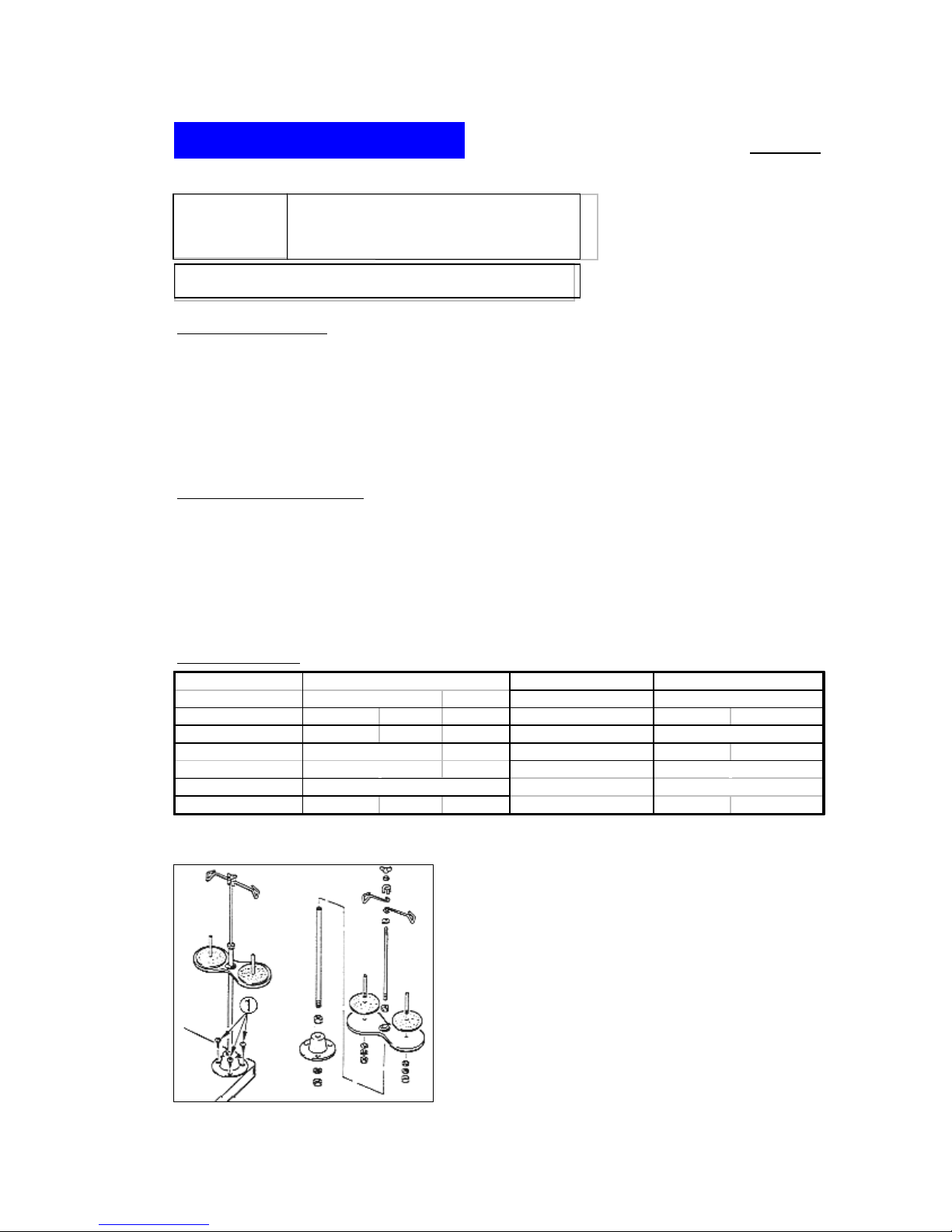

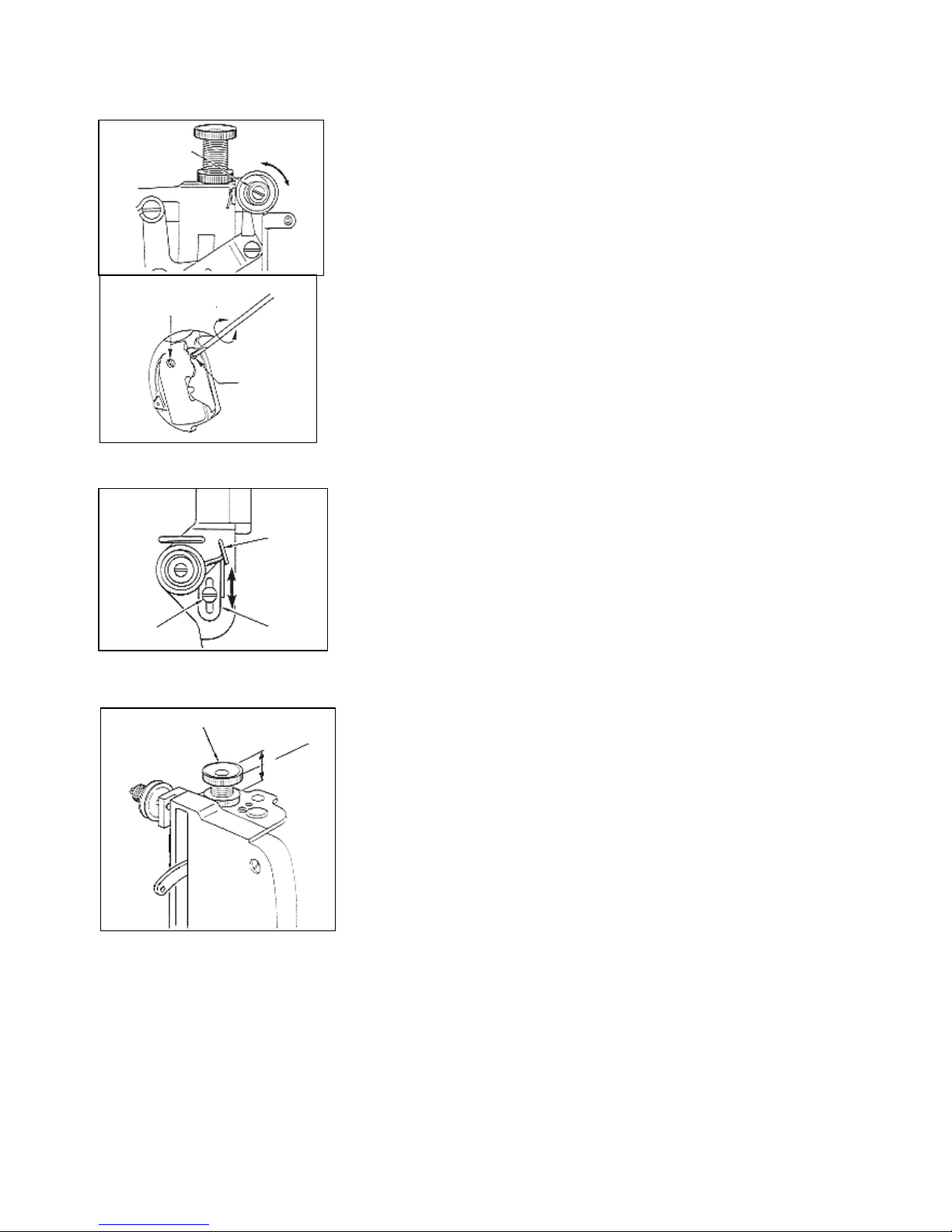

13] THREAD TENSION

◆ Adjusting the needle thread tension

Adjusting the needle thread tension by thread

tension nut ①.

To increase the needle thread tension, turn

the nut to the clockwise Ⅰ.

To decrease the needle thread tension, turn

the nut to the counterclockwise Ⅱ.

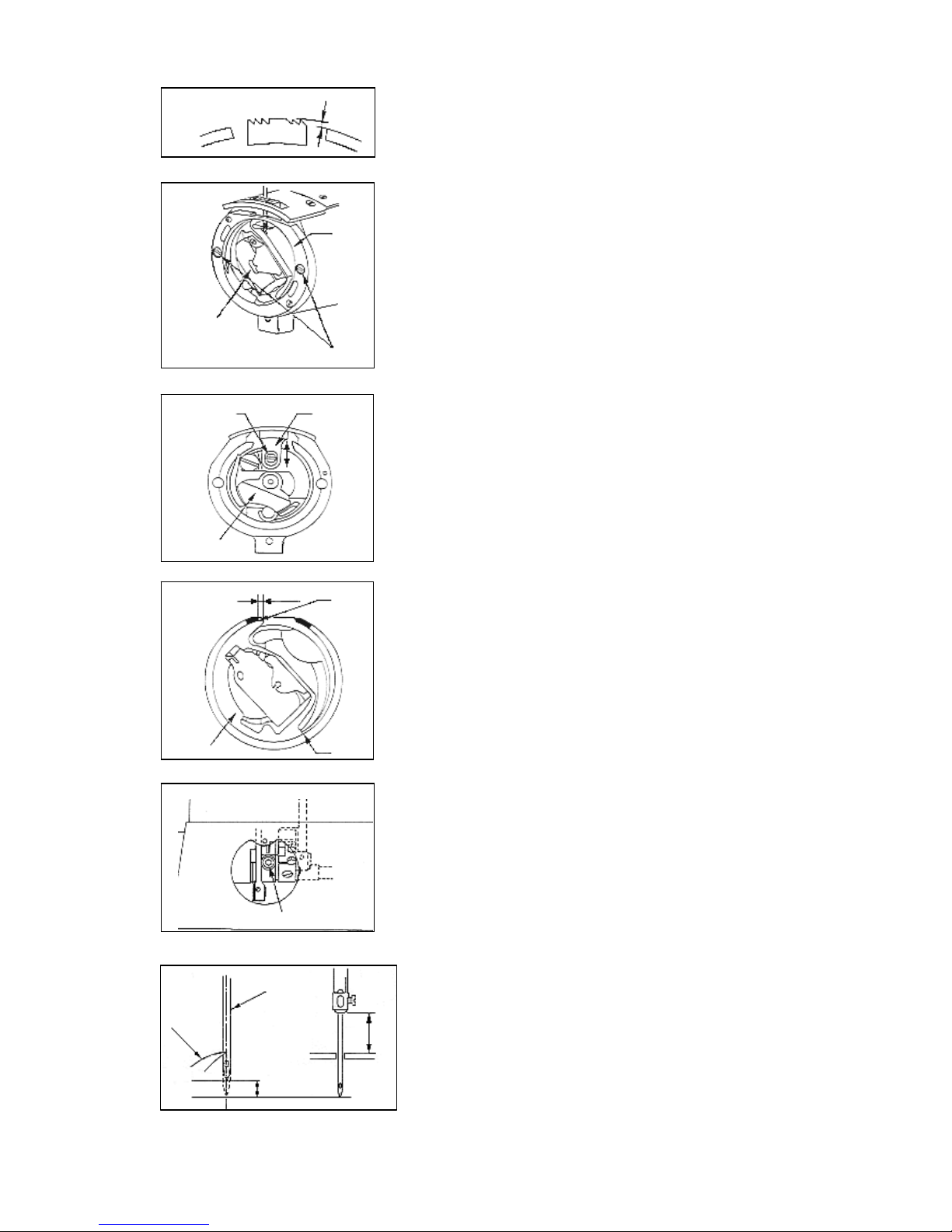

◆ Adjusting the bobbin thread tension

To adjust the bobbin thread tension

1. Loosen screw ①.

2. Adjust the bobbin thread tension by turning

screw ②.

To increase the bobbin thread tension, turn

the screw to the clockwise Ⅰ.

To decrease the bobbin thread tension, turn

the screw to the counterclockwise Ⅱ.

3. After the bobbin thread tension has been

adjusted, tighten screw ① firmly.

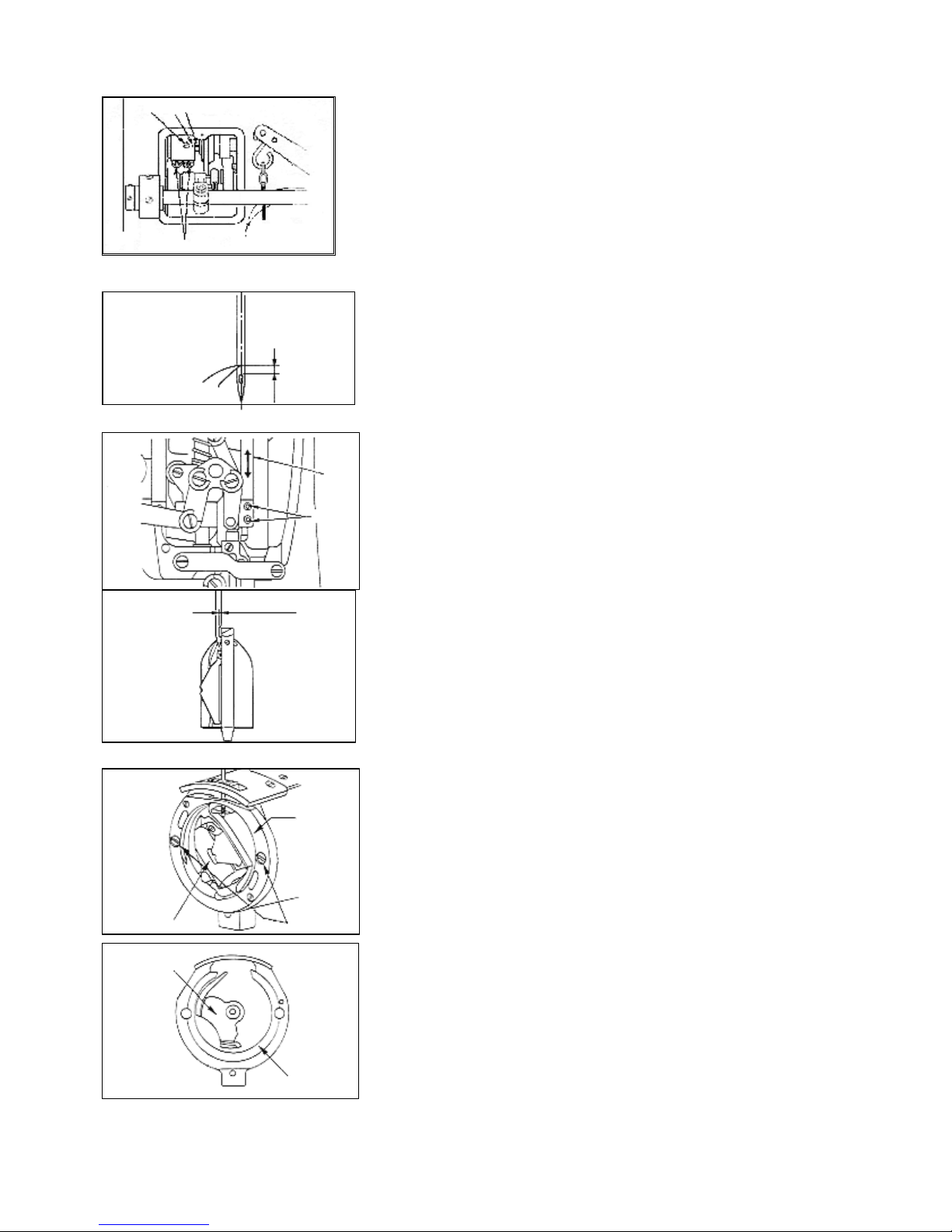

14] THE THREAD TAKE-UP SPRING

The standard stroke of thread take-up spring ①

is 8 to 15 mm.

To adjust the operating range;

1. Loosen screw ②.

2. Adjust the operating range by moving thread

the take-up spring adjusting plate ③ up and

down.

3. After adjustment has been completed,

tighten screw ② firmly.

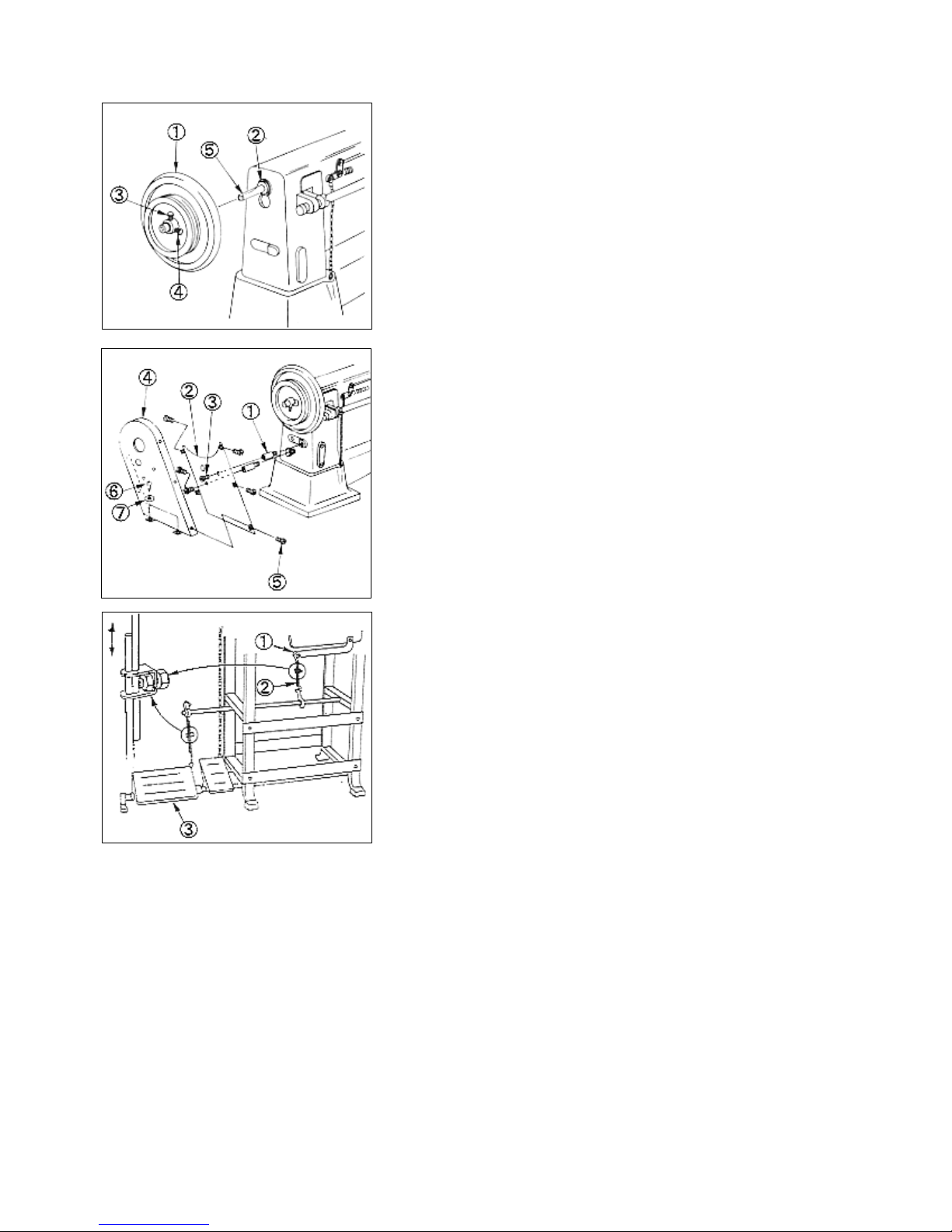

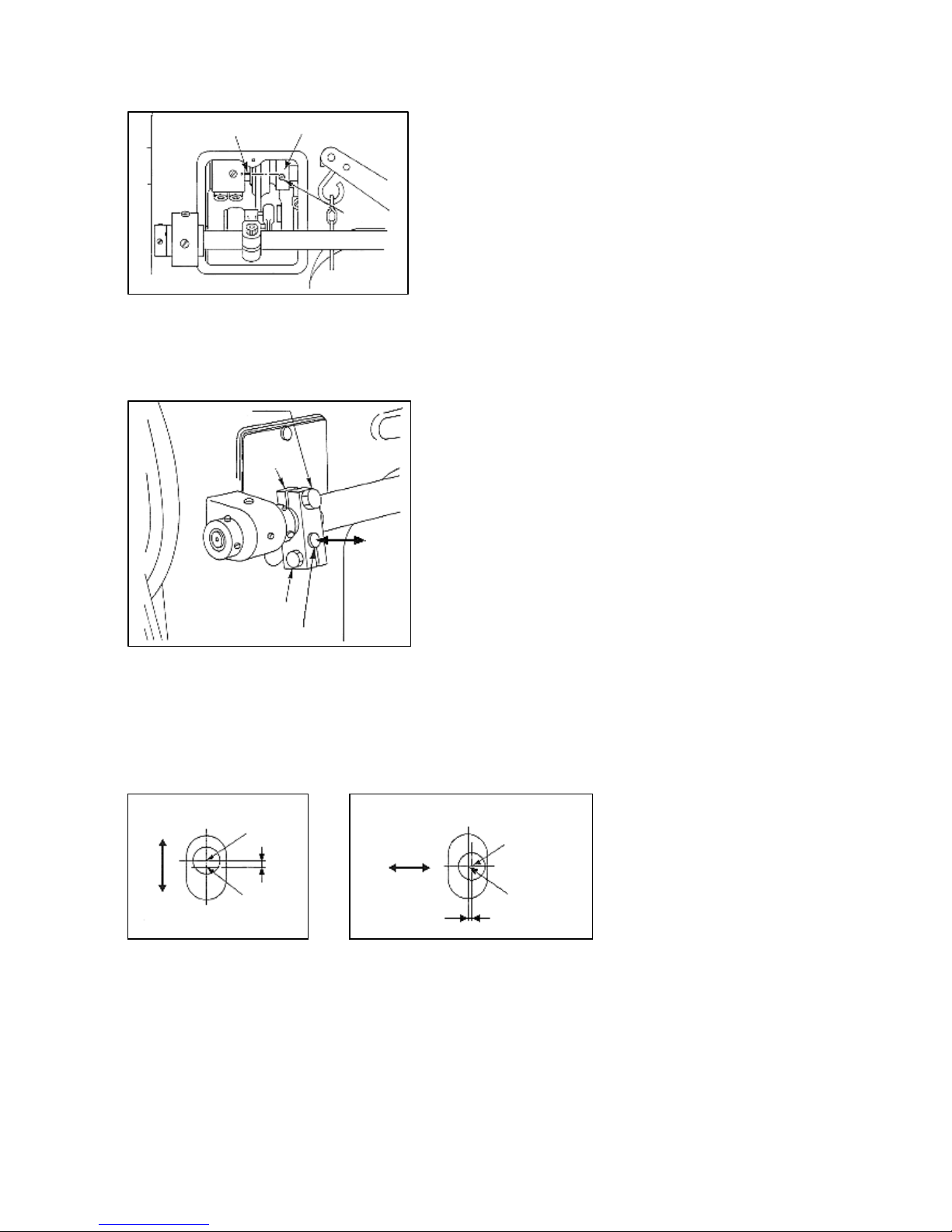

15] ADJUSTING THE PRESSER FOOT PRESSURE

The standard height of presser spring regulator ①

30mm above the main unit surface.

The presser foot pressure for the presser foot and

walking foot can be adjusted according to the material

to be sewn.

To adjust the presser foot pressure

1. Loosen the presser spring regulator nut.

2. Turn the presser spring regulator clockwise to inc

-rease the pressure of the presser foot, or count

-erclockwise to decrease it.

3. After adjustment has been completed, turn the nut

firmly, making sure to keep it securely in place.

・ Use a minimum amount of required pressure.

①Ⅰ

Ⅱ

①