Replacing the Reciprocator on the SWF

Compact Series Machine (601C and 1201C)

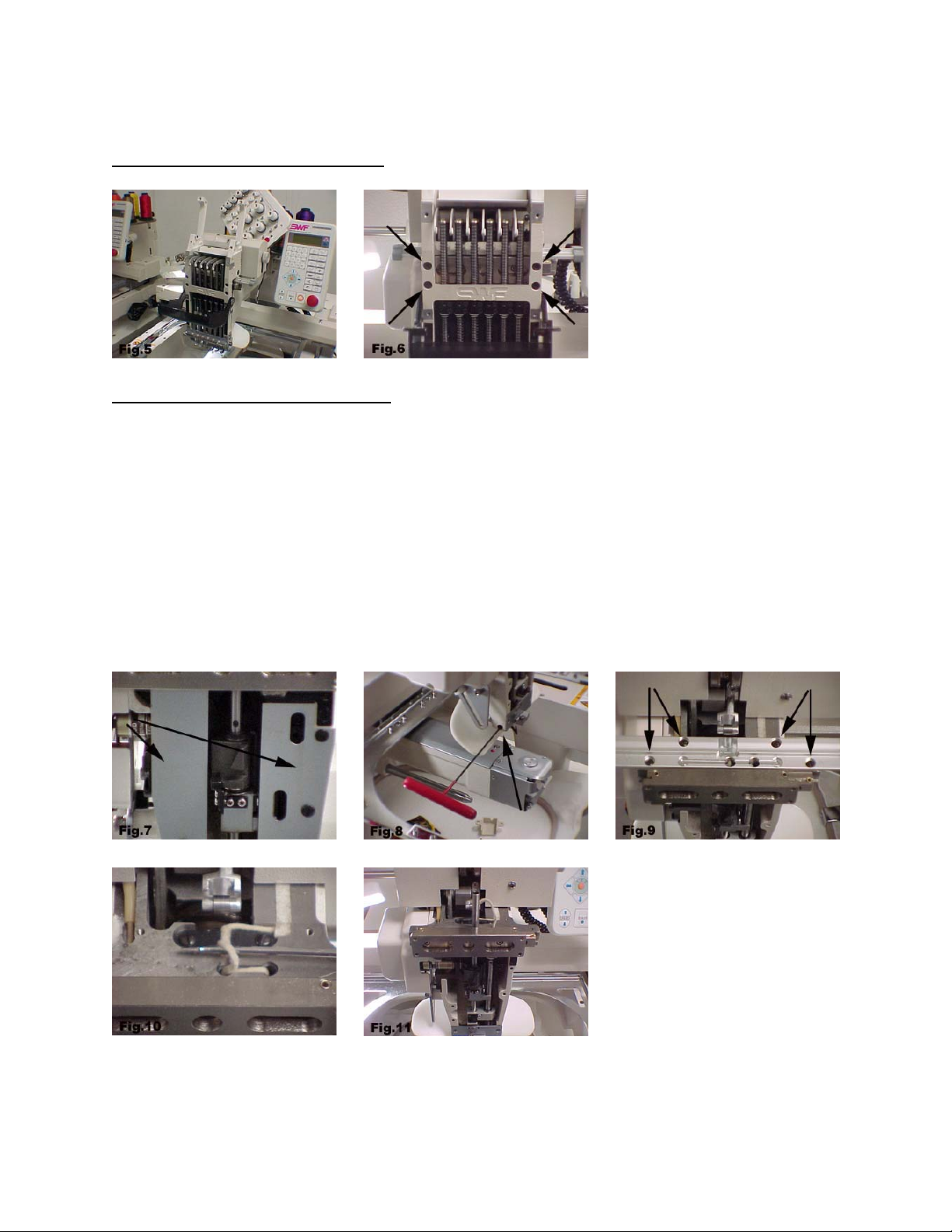

Installing the new reciprocator

1. Holding the reciprocator upright, guide the pin on the back side into the hole at the

bottom of the connecting rod.

2. Move the assembly slightly to align the guides around the presser foot driving shaft

located to the right.

3. Before inserting the driving shaft back down through the top of the head, notice that the

bottom end has a flat side. (Fig.12) As you insert the shaft, align this side to the left and

keep it facing that direction at all times.

4. Slide the shaft down through the reciprocator, continuing all the way down through the

felt gasket and round bearing at the bottom of the head. It may be necessary to remove

the plate holding the bearing in place to get the shaft to slide easily through the bearing.

(Fig.13)

5. The shaft should slide completely down until the top is flush with the bottom of the

channels cut for the wicks. (Fig.14)

6. Once the shaft is in place, tighten the 2mm screw in the hole at the bottom left of the

head that you loosened in step 2 of removing the broken reciprocator.

7. If you removed the bearing guide plate in step 4 above, replace it now.

8. Using a small screwdriver, press the wicks back down into the driving shaft.

9. Replace the take up lever guide rail. Center the screws in the holes of the rail as close

as possible before tightening.

10. Replace the left and right cover plates. The plates should sit flush on top of the bearing

guide plate you replaced earlier.

Remounting the Needle Case

1. Holding the needle case upright, line up the wiper hook under the head to fit into the

thread holding bracket at the bottom of the needle case. This bracket is just behind the

presser feet on the needle case and lined with a soft, Velcro-like material. The hook end

of the wiper should pass between two pieces of material.

2. Set the lower lip of the needle case (Fig.15) into, or behind the small bearing at the

bottom of the head (Fig.16). Tilt the needle case up, and with light upward pressure, set

the top of the case down onto the take up lever guide rail. If mounted properly, there

should be virtually no movement of the needle case. It may take two or more attempts

to get the needle case to seat properly on top of the head. Tip: use a rubber band to

hold all the take up levers level as you put the needle case back on the head. This will

help to keep them all at the same position during the remount procedure.

Page 3 of 5