Page 3

This manual explains the proper installation and use of your appliance, please read it carefully before using even if you are familiar with

the product. The manual should be kept in a safe place for future reference. In case of failure, only the Authorized Technical Service

may repair this hob. Otherwise the guarantee will be null and void.

Warning

General safety

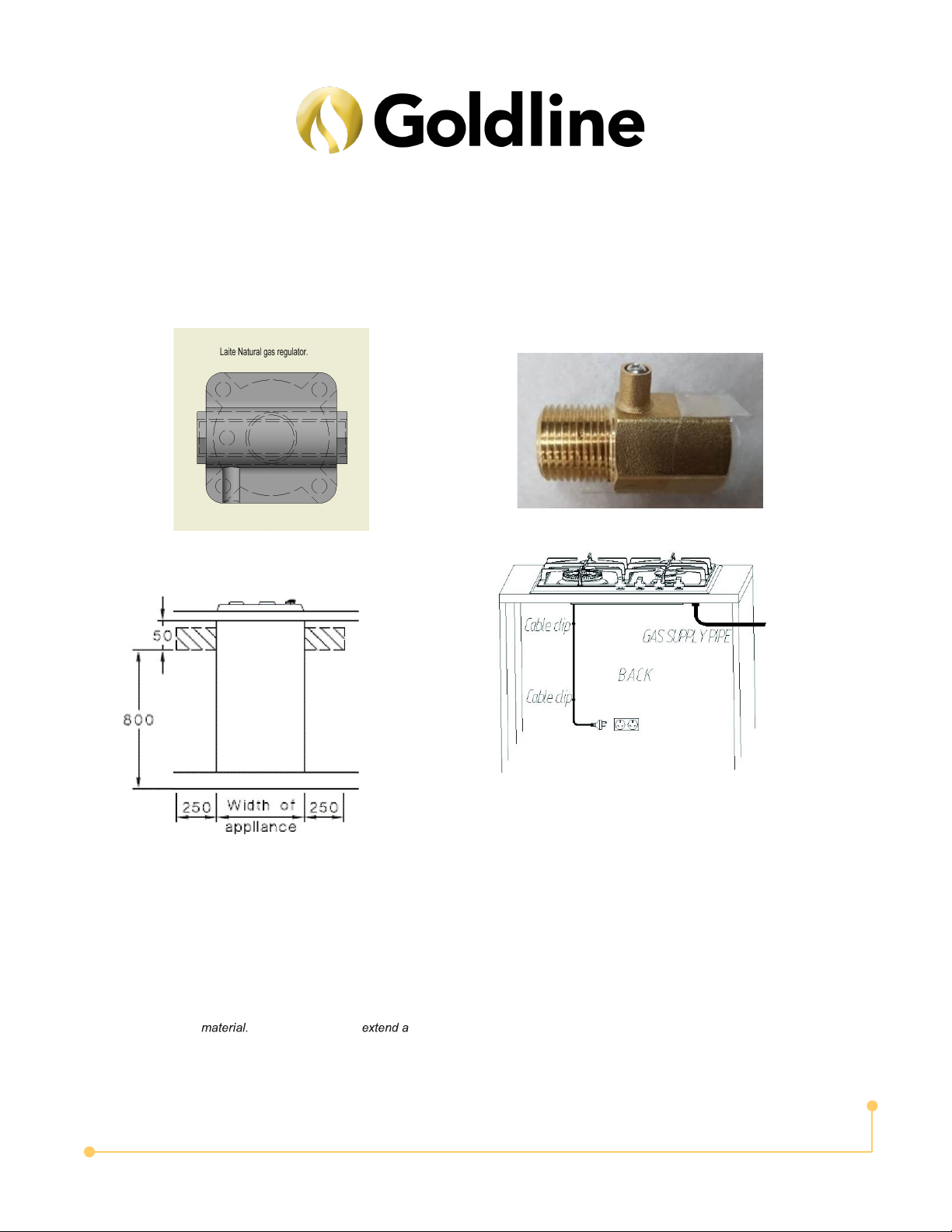

The appliance may only be installed and connected by trained, Authorised persons.

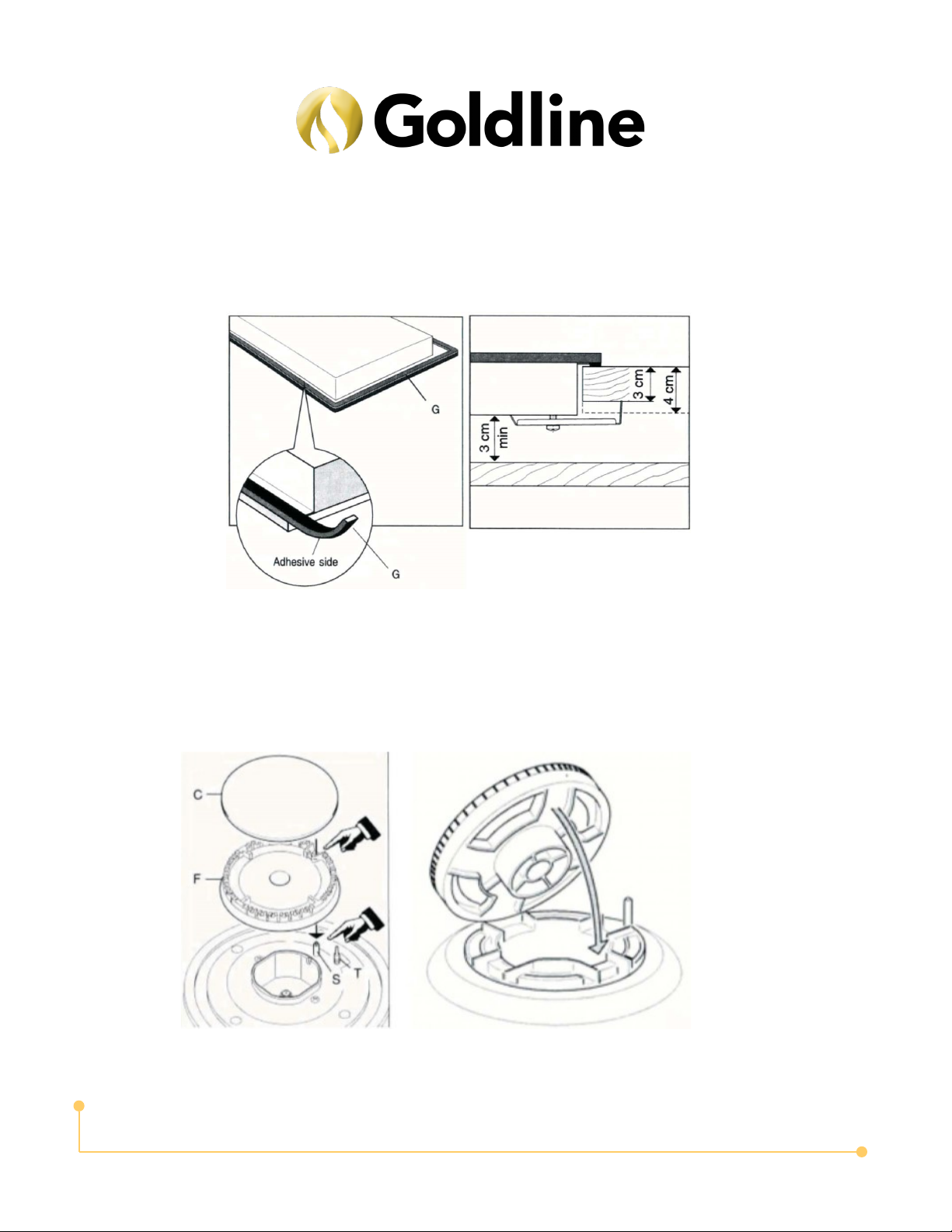

Built-in appliances may only be used after they have built in to suitable built-in units and work surfaces that

meet standards.

In the event of faults with the appliance or damage to the glass toughened (cracks, scratches or splits), the appliance

must be switched off and disconnected from the electrical supply, to prevent the possibility of an electric shock.

Repairs to the appliance must only be carried out by trained Authorised persons.

The technical and identification data for the hob figure on the reference plate fixed to the appliance.

This reference plate must be consulted before making the electrical connections.

The electrical connections must be made by specialist aware to the legal and regulatory, requirements in each

country.

If the cable is damaged in any way it must be replaced by the manufacturer or after sale service or by authorized

technical staff, to avoid hazard. Correct use

People (including children) who, because of their physical, sensory or mental capabilities or their inexperience or

ignorance are not able to use the device safely, should not use this device without supervision or instruction by a

responsible person.

This appliance should be used only for normal domestic cooking and frying of food.

The appliance must not be used as a work surface or as a storage surface.

Additions or modifications to the appliance are not permitted.

Do not place or store flammable liquids, highly inflammable materials or fusible objects (e.g. plastic film, plastic,

aluminum, cardboard) on or near or below cupboards and drawers the appliance.

Do not heat an empty pan on the appliance.

Do Not Use this Appliance as Space Heater

We don’t recommend after market lids or cover fitted with this product.

When the appliance is installed in a marine craft or in a caravan, it shall not be used as a space heater.

Do Not Modify This Appliance.

Children's safety

The cooking zones will become hot when you cook. Therefore, always keep small children away from the appliance.

The appliance is not intended for use by young children or infirm persons without supervision.

Young children should be supervised to ensure that they do not play with the appliance.

Safety during use

Remove stickers and film from the glass ceramic.

There is the risk of burns from the appliance if used carelessly.

Cables from electrical appliances must not touch the hot surface of the appliance or hot cookware.

Overheated fats and oils can ignite very quickly. Warning! Fire hazard!

Switch the cooking zones off after each use.

Users with implanted pacemakers should keep their upper body at least 30 cm from cooking zones that are switched

on.

Risk of burns! Do not place objects made of metal, such as knives, forks, spoons and saucepan lids on the cooking

surface, as they can get hot.