FUNCTION GENERATOR USER MANUAL

17

14a

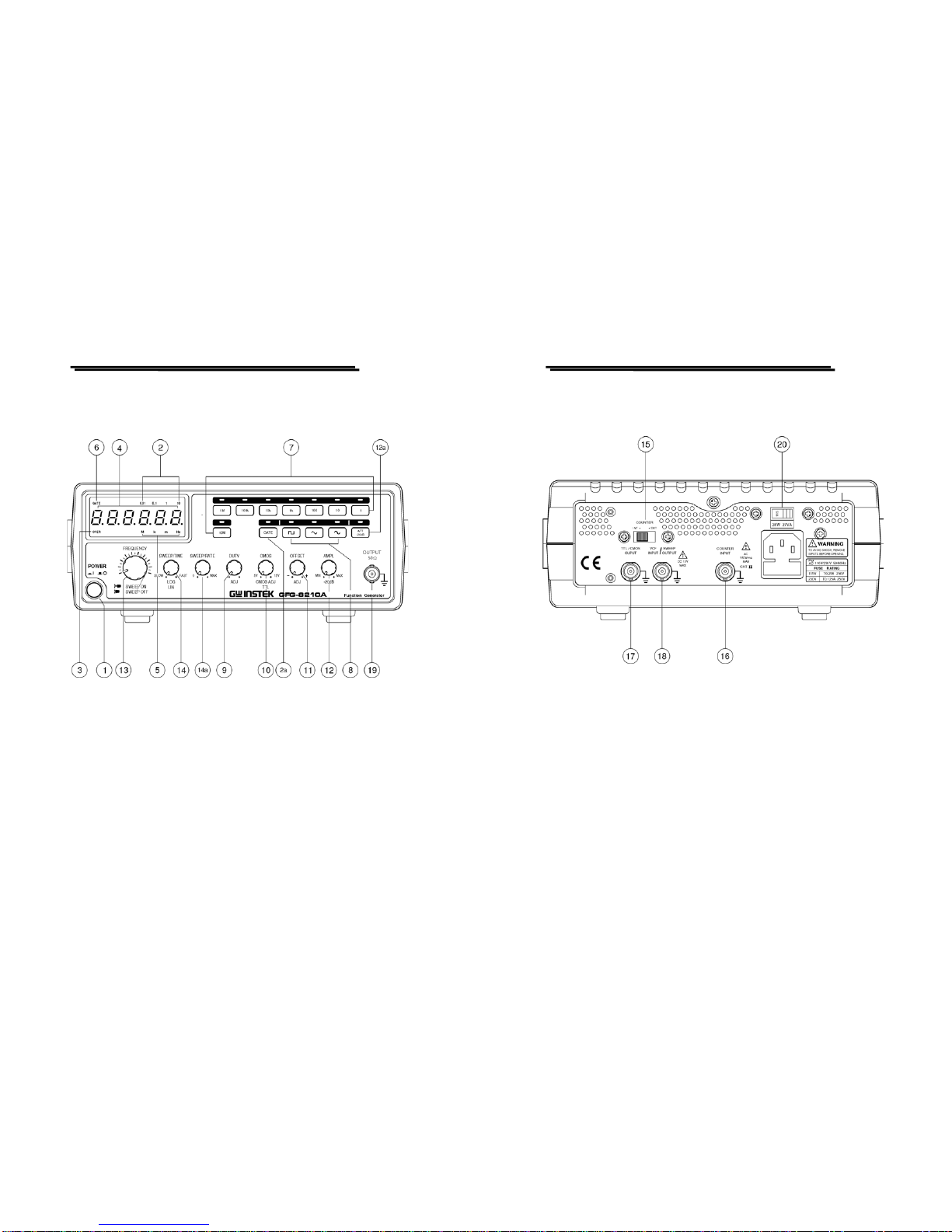

5-6.Variation of external voltage-controlled frequency

This mode of operation allows the user to adjust the frequency of the

function generator with an external DC control Voltage. It also provides

an easy way for your adjustment.

(1) Select Function

8

first, then select Range

7

, rotate FREQ

13

to set required frequency range.

(2) Connect external control voltage (0~10V) to the VCF

connector via a suitable lead, and generate signal from Output .

(3) Other adjustments, such as AMPL

12

switch can change

amplitude of signal, or get attenuation; adjust Offset 11 for DC

level, rotate Duty kswitch can change output signal of pulse or

ramp waveform etc..

5-7.Auto Sweep

(1) First select the required waveform by pressing Function

8

button,

then select required frequency range by pressing range

7

push

button.

(2) Connect output terminal to oscilloscope for observing output

signal.

(3) Rotate frequency

13

to determine the upper limit frequency.

(4) Pull out frequency

13

to perform auto-sweep operation.

(5) Rotate SWEEP/TIME 14 and SWEEP/RATE to adjust

sweep time and rate.

(6) Pull out (press) LIN/LOG 14 to obtain LOG (LIN) sweep mode.

Note: The sweep width can only be adjusted during the sweep cycle

and it can not be stopped.

FUNCTION GENERATOR USER MANUAL

18

5-8. Precaution item

(1) Adjust DC OFFSET, will provide to change voltage of ±10V (no

load) or ±5V (50Ωload). However, signal added DC level, is

still limited to ±20V (no load) or ±10V (50Ωload). In case of

over-voltage, clip will appear as shown in Figure 2:

(2) Output connector label 50 Ω, indicated that signal source

impedance is 50Ω. Connect to any of impedance circuit, but

output voltage and terminal impedance will be rated. To avoid

oscillation, terminal shall be connected to 50Ω(When using high

frequency and square output), and its connecting line shall be as

short as possible.

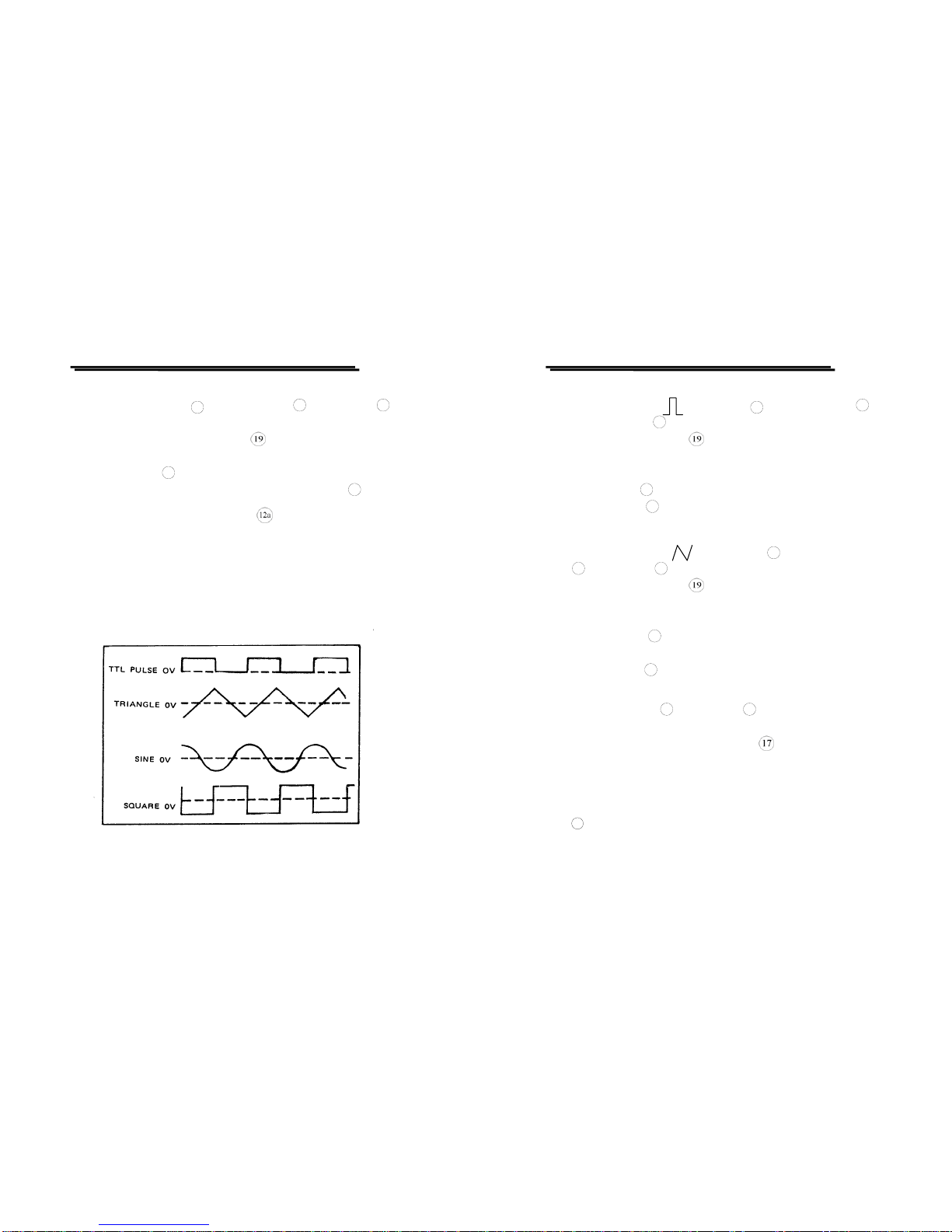

(3) When adjust Duty knob to leftward position, the ratio of positive

state to negative state, expand to not less than 80:20. It can expand

Square wave to Pulse wave, expand Triangle wave to Ramp wave

and Sine wave to unsymmetrical Sine wave. As shown in Figure 3

is for adjustment of Duty control to obtain required waveform.