4

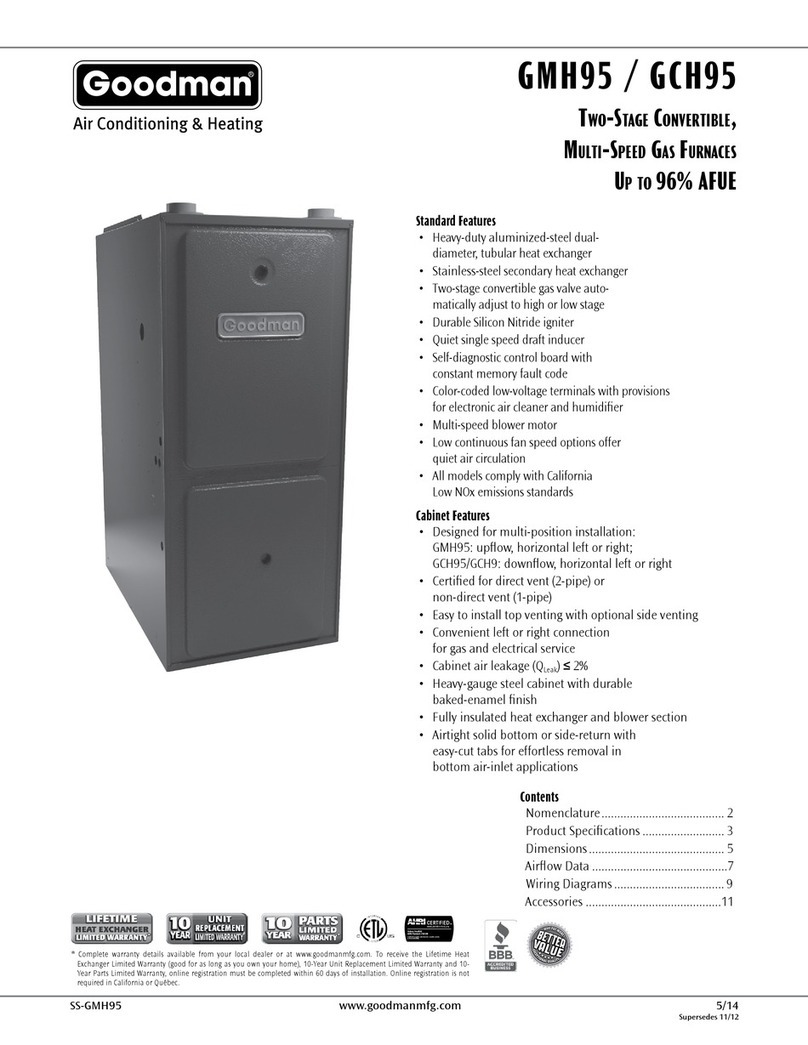

PRODUCT DESIGN

NFPA 54/ANSI Z223.1 - latest edition. In Canada, the fur-

nacesmustbeventedinaccordancewiththeNationalStan-

dardof Canada, CAN/CSAB149.1and CAN/CSA B149.2-

latesteditions and amendments.

NOTE: Thevertical height of theCategory I venting system

must be at least as great as the horizontal length of the

ventingsystem.

Accessibility Clearances (Minimum)

Unobstructed front clearanace of 24" for servicing is rec-

ommended.

SW B

103 6 1 1

* 24" clearnace for serviceability recommended.

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIALS - INCHES

** Single Wall Vent (SW) to be used only as a conncetor.

Refer to the venting tables outlined in the Installation Manual for

additional venting requirements.

Vent

Sides TopRear Front*

Note: Inall cases accessibilityclearance shalltake prece-

denceoverclearancesfromtheenclosurewhereaccessibil-

ityclearancesaregreater. Alldimensionsaregivenininches.

HighAltitudeDerate

IMPORTANT NOTE: The furnace as shipped requires no

change to run between 0 - 4500 feet. Do not attempt to

increase the firing rate by changing orifices or increasing

themanifoldpressurebelow4500feet.Thiscan cause poor

combustionand equipment failure.

Highaltitudeinstallationsabove 4500 feetmayrequireboth

a pressure switch and an orifice change. These changes

are necessary to compensate for the natural reduction in

the density of both the gas fuel and the combustion air at

higheraltitude.

For installations above 4500 feet, please refer to your dis-

tributorfor required kit(s).Contactthe distributor fora tabu-

lar listing of appropriate manufacturer’s kits for propane

gasand/orhighaltitudeinstallations.Theindicatedkitsmust

be used to insure safe and proper furnace operation. All

conversions must be performed by a qualified installer, or

service agency.

GeneralOperation

TheGMS8furnacesareequippedwithanelectronicignition

deviceusedtolightthe burners and aninduceddraftblower

to exhaust combustion products.

An interlock switch prevents furnace operation if the inner

blowerdoor is notin place.Keep the bloweraccess door in

placeexcept for inspectionand maintenance. (Seeillustra-

tion on pages 5 and 6.)

This furnace is also equipped with a self-diagnosing elec-

tronic control module. In the event a furnace component is

notoperatingproperly,thecontrolmoduleLED will flashon

and off in a factory-programmed sequence, depending on

theproblem encountered. Thislight can beviewedthrough

theobservation window in theblower access door. Referto

theTroubleshootingChart forfurtherexplanationoftheLED

codesand Abnormal Operation -IntegratedIgnitionControl

section in the Service Instructions for an explanation of the

possibleproblem.

Theratedheating capacity ofthefurnace should begreater

thanor equal tothe totalheat loss ofthe area tobe heated.

The total heat loss should be calculated by an approved

methodorin accordance with“ASHRAEGuide” or “Manual

J-LoadCalculations”publishedbytheAirConditioningCon-

tractors of America.

*Obtain from: American National Standards Institute 1430

BroadwayNewYork, NY 10018

LocationConsiderations

• The furnace should be as centralized as is practical

with respect to the air distribution system.

• Donotinstall the furnacedirectlyoncarpeting, tile, or

combustiblematerialother than woodflooring.

• When installed in a residential garage, the furnace

mustbepositionedsotheburnersandignitionsource

are located not less than 18 inches (457 mm) above

the floor and protected from physical damage by ve-

hicles.

Notes:

WARNING

TO PREVENT POSSIBLE PERSONAL INJURY OR DEATH DUE TO ASPHYXIATION,

THIS FURNACE MUST BE CATEGORY IVENTED. DO NOT VENT USING

CATEGORY III VENTING.

CategoryI Venting isventing at anon-positive pressure. A

furnace vented as Category I is considered a fan-assisted

appliance and the vent system does not have to be “gas

tight.” NOTE: Singlestagegas furnaces withinduceddraft

blowers draw products of combustion through a heat ex-

changerallowing, in someinstances,common venting with

naturaldraftappliances (i.e. waterheaters).Allinstallations

mustbeventedin accordance withNationalFuelGasCode