4

PRODUCT DESIGN

NFPA 54/ANSI Z223.1 - latest edition. In Canada, the fur-

nacesmust be ventedinaccordancewiththe National Stan-

dardofCanada, CAN/CSA B149.1 and CAN/CSA B149.2-

latesteditions and amendments.

NOTE: Theverticalheightof the Category I ventingsystem

must be at least as great as the horizontal length of the

ventingsystem.

Accessibility Clearances (Minimum)

Unobstructed front clearanace of 24" for servicing is rec-

ommended.

SW B

1036 11

* 24" clearnace for serviceability recommended.

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIALS - INCHES

** Single Wall Vent (SW) to be used only as a conncetor.

Refer to the venting tables outlined in the Installation Manual for

additional venting requirements.

Vent

Sides TopRear Front*

Note: Inall cases accessibility clearance shall take prece-

denceover clearancesfromtheenclosure where accessibil-

ityclearancesaregreater. Alldimensionsaregivenininches.

High Altitude Derate

Whenthis furnace is installedat high altitude, theappropri-

ate High Altitude orifice kit must be installed. This is re-

quiredduetothenatural reduction in the density of boththe

gas fuel and combustion air as altitude increases. The kit

will provide the proper design certified input rate within the

specifiedaltituderange.

2000 3000 4000 4500 5000 6000 7000 8000

US BURNER

ORIFICE 44/55 44/55 45/56 45/56 46/57 47/58 47/58

CANADA BURNER

ORIFICE 44/55 47/57

HA-02 HIGH ALTITUDE CONVERSION KIT REQUIRED

Tabled data is based upon the furnace input being reduced for altitudes above sea level. U.S. 4% per 1,000 feet.

Canada 10% derate for 2,000-4,000 feet.

ELEVATION ABOVE SEA-LEVEL (FEET)

INPUT PER BURNER - 22,500 BTUH NATURAL GAS / 20,000 BTUH L.P.

High altitude kits are purchased according to the installa-

tionaltitudeandusageof eithernatural orpropanegas.Refer

tothechartaboveforatabular listing of appropriate altitude

rangesandcorrespondingmanufacturer’shighaltitudeNatu-

ralGasandPropaneGaskits.For a tabular listing of appro-

priatealtituderangesandcorrespondingmanufacturer'sHigh

Altitude Pressure Switch kits, refer to either the Pressure

Switch Trip Points & Usage Chart in this manual or the Ac-

cessoryCharts in Service Instructions.

GeneralOperation

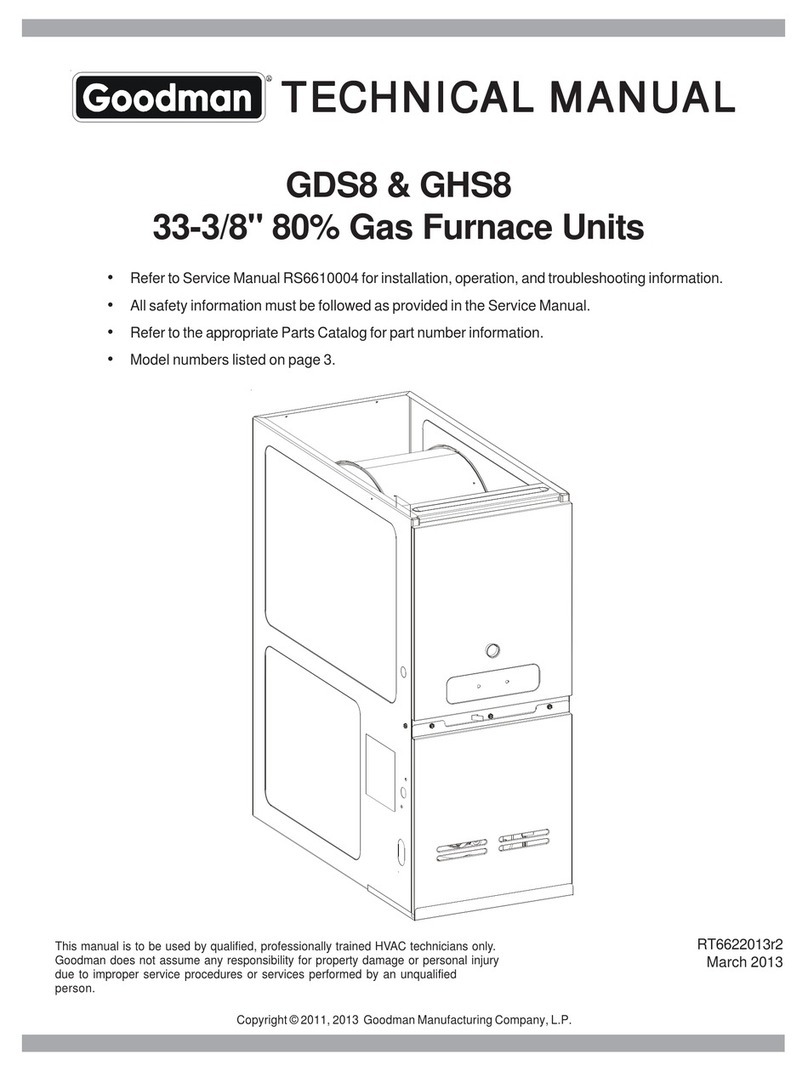

TheG*S8furnaces are equipped with anelectronicignition

deviceused to light the burners and an induced draft blower

to exhaust combustion products.

An interlock switch prevents furnace operation if the inner

blowerdoor is not inplace. Keep the blower access door in

placeexceptfor inspection and maintenance.(See illustra-

tion on pages 5 and 6.)

This furnace is also equipped with a self-diagnosing elec-

tronic control module. In the event a furnace component is

notoperating properly, the controlmoduleLED will flashon

and off in a factory-programmed sequence, depending on

theproblemencountered. This light canbe viewed through

theobservationwindowin the blower access door.Referto

theTroubleshootingChartforfurther explanation oftheLED

codesandAbnormal Operation - Integrated Ignition Control

section in the Service Instructions for an explanation of the

possibleproblem.

Theratedheatingcapacityof the furnace should be greater

thanor equal to the total heat lossof the area to be heated.

The total heat loss should be calculated by an approved

methodorinaccordance with “ASHRAE Guide” or “Manual

J-LoadCalculations” published by theAirConditioningCon-

tractors of America.

*Obtain from: American National Standards Institute 1430

BroadwayNewYork,NY10018

LocationConsiderations

• The furnace should be as centralized as is practical

with respect to the air distribution system.

• Donotinstallthefurnacedirectly on carpeting, tile, or

combustiblematerialotherthanwood flooring.

• When installed in a residential garage, the furnace

mustbe positioned so theburnersandignitionsource

are located not less than 18 inches (457 mm) above

the floor and protected from physical damage by ve-

hicles.

Notes:

WARNING

TO PREVENT POSSIBLE PERSONAL INJURY OR DEATH DUE TO ASPHYXIATION,

THIS FURNACE MUST BE CATEGORY IVENTED. DO NOT VENT USING

CATEGORY III VENTING.

CategoryI Venting is ventingat a non-positive pressure. A

furnace vented as Category I is considered a fan-assisted

appliance and the vent system does not have to be “gas

tight.” NOTE: Singlestagegasfurnaceswithinduced draft

blowers draw products of combustion through a heat ex-

changerallowing,in some instances, common ventingwith

naturaldraftappliances(i.e.waterheaters). All installations

mustbeventedinaccordancewithNationalFuelGasCode