OM-05171 60 SERIES

PAGE B - 2 INSTALLATION

c. Carefully read all tags, decals and markings

on the pump assembly, and follow the instruc

tions indicated.

d. Check all lubricant levels and lubricate as

necessary. Refer to LUBRICATION in the

MAINTENANCE AND REPAIR section of this

manual and perform duties as instructed.

e. If the pump and engine have been stored for

more than 12 months, some of the compo

nents or lubricants may have exceeded their

maximum shelf life. These must be inspected

or replaced to ensure maximum pump serv

ice.

f. Check to ensure the following standard

equipment items are included with the pump

assembly:

SPortable 6.5 gallon fuel tank complete with

quick‐connect fitting.

SSuction strainer.

SRubber foot mounting kit (must be

installed). To install feet, position flat wash

ers on capscrews, slide the capscrews

through the rubber feet and holes in the

base, and secure with the flanged hex nut.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman‐Rupp distributor or the factory to deter

mine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

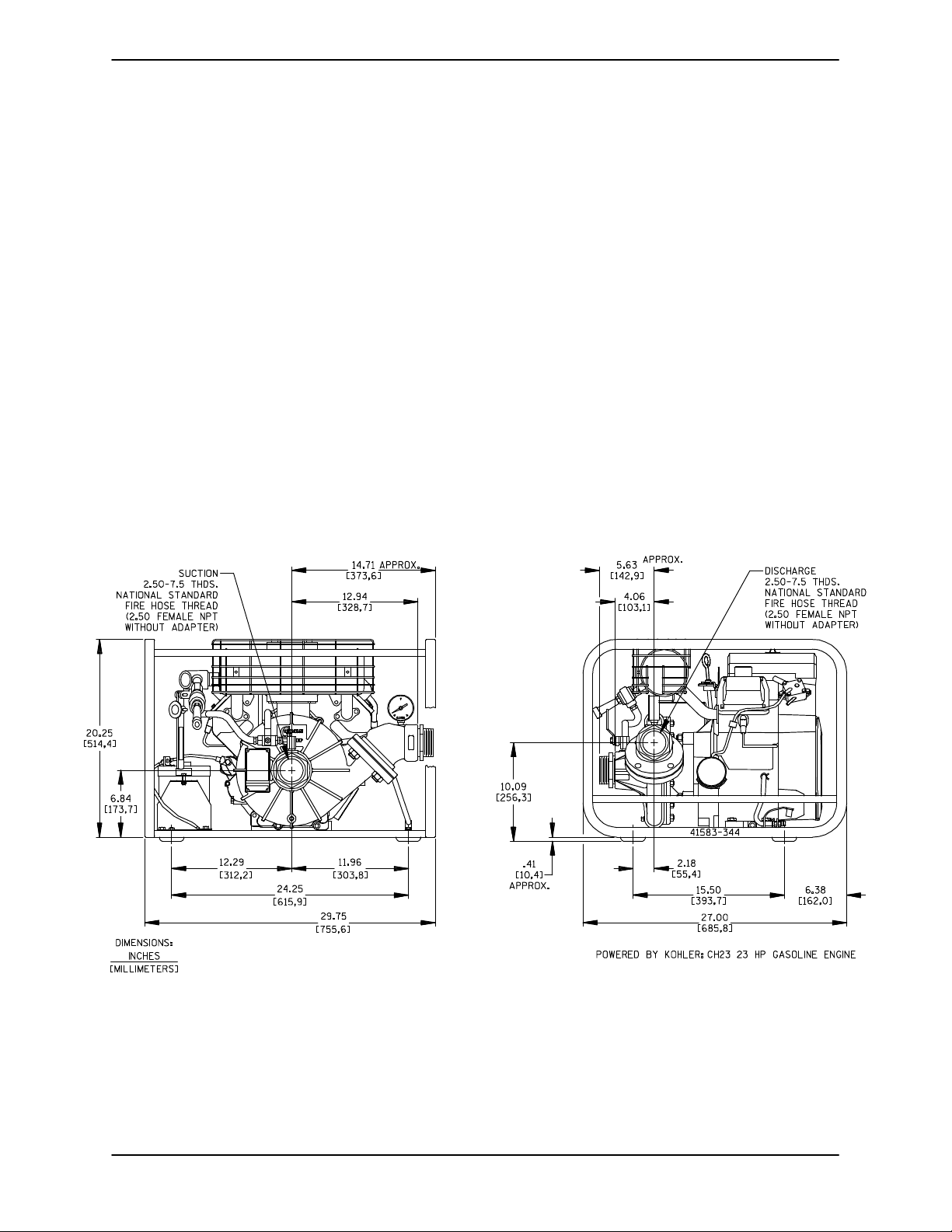

POSITIONING PUMP

This pump is designed to be very light‐weight and

portable. The total pump weight is approximately

240 pounds (109 kg), not including accessories

or engine fuel. Customer installed equipment such

as suction and discharge hoses must be removed

before attempting to lift.

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mount

ing is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibra

tion.

To ensure sufficient lubrication and fuel supply to

the engine, do not position the pump and engine

more than 15_off horizontal for continuous opera

tion. The pump and engine may be positioned up

to 30_off horizontal for intermittent operation

only; however, the engine manufacturer should be

consulted for continuous operation at angles

greater than 15_.

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by in

creased suction lift, discharge elevation, and fric

tion losses. See the performance curve and oper

ating range shown on Page E‐1 to be sure your

overall application allows pump to operate within

the safe operation range.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid‐wall, rein

forced type to prevent collapse under suction. Us

ing piping couplings in suction lines is not recom

mended.

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make mini

mum use of elbows and fittings, which substan

tially increase friction loss. If elbows are necessary,

use the long‐radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it ex

actly with the pump port. Never pull a pipe line into

place by tightening the flange bolts and/or cou

plings.

Lines near the pump must be independently sup

ported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose‐type

lines are used, they should have adequate support

to secure them when filled with liquid and under

pressure.

Gauges

Most pumps are drilled and tapped for installing

discharge pressure and vacuum suction gauges. If