sotera.com 4

| 820,825, 850 DIGITAL PULSE OUTPUT METERS INSTALLATION AND OPERATION MANUAL

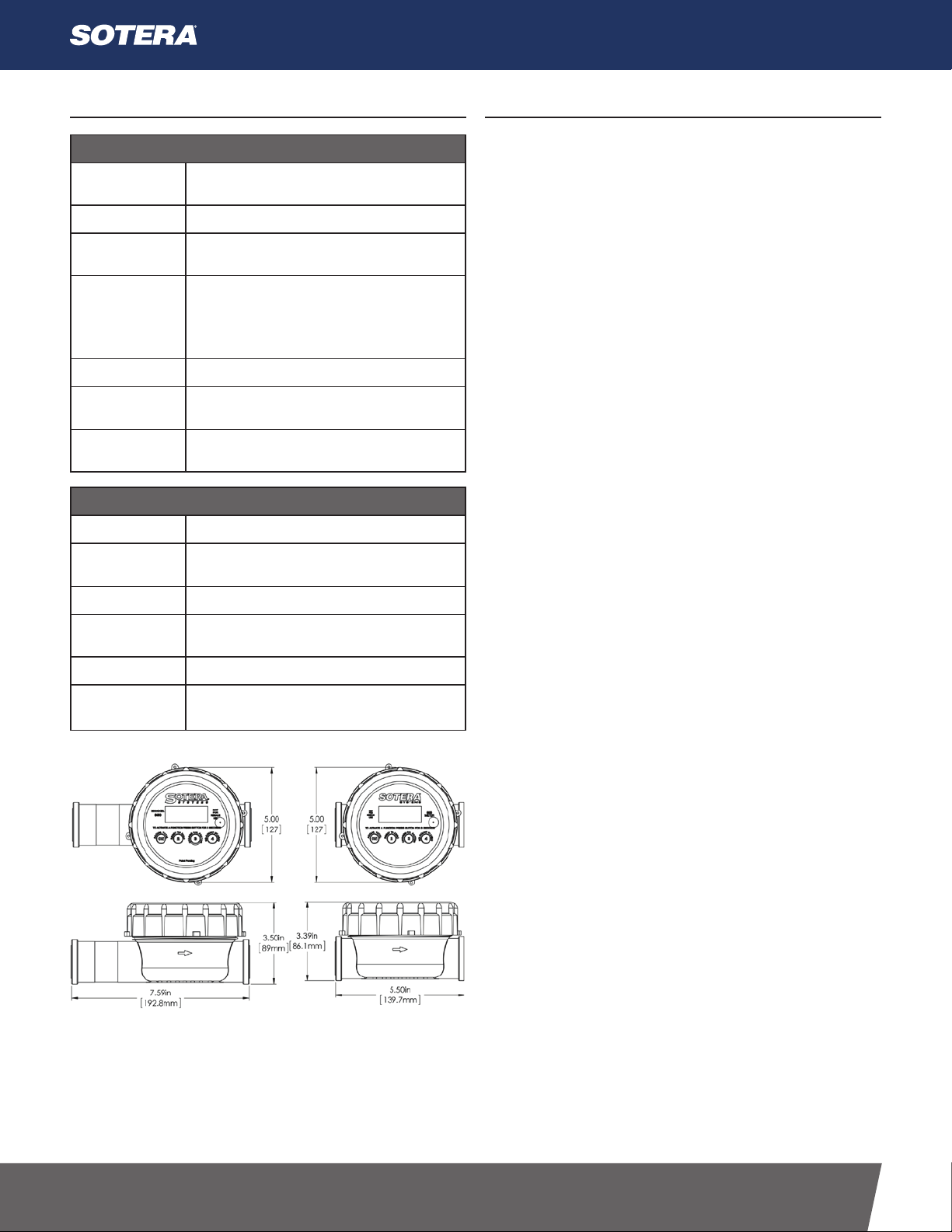

Technical Information

Flow ports 1" NPT inlet / outlet ports, female threads

(3/4" BSPP also available)

Flow Range 2 to 20 U.S GPM / 7.6 to 75.7 LPM

Pressure 120 PSI / 8.2 Bar maximum @ 70°F / 21°C

50 psi / 3.4 Bars maximum @ 130°F / 54°C

Temperature Min. operating temperature = 0°F / 17°C

Max. operating temperature = 130°F / 54°C

Meter can be stored at lower temperatures but

display may not work below 0°F.

Accuracy ± 0.5%

Units of Measure Ounces, pints, quarts, liters, gallons;

special calibration option also available.

Range 9999 current total;

10,000,000 accumulated total

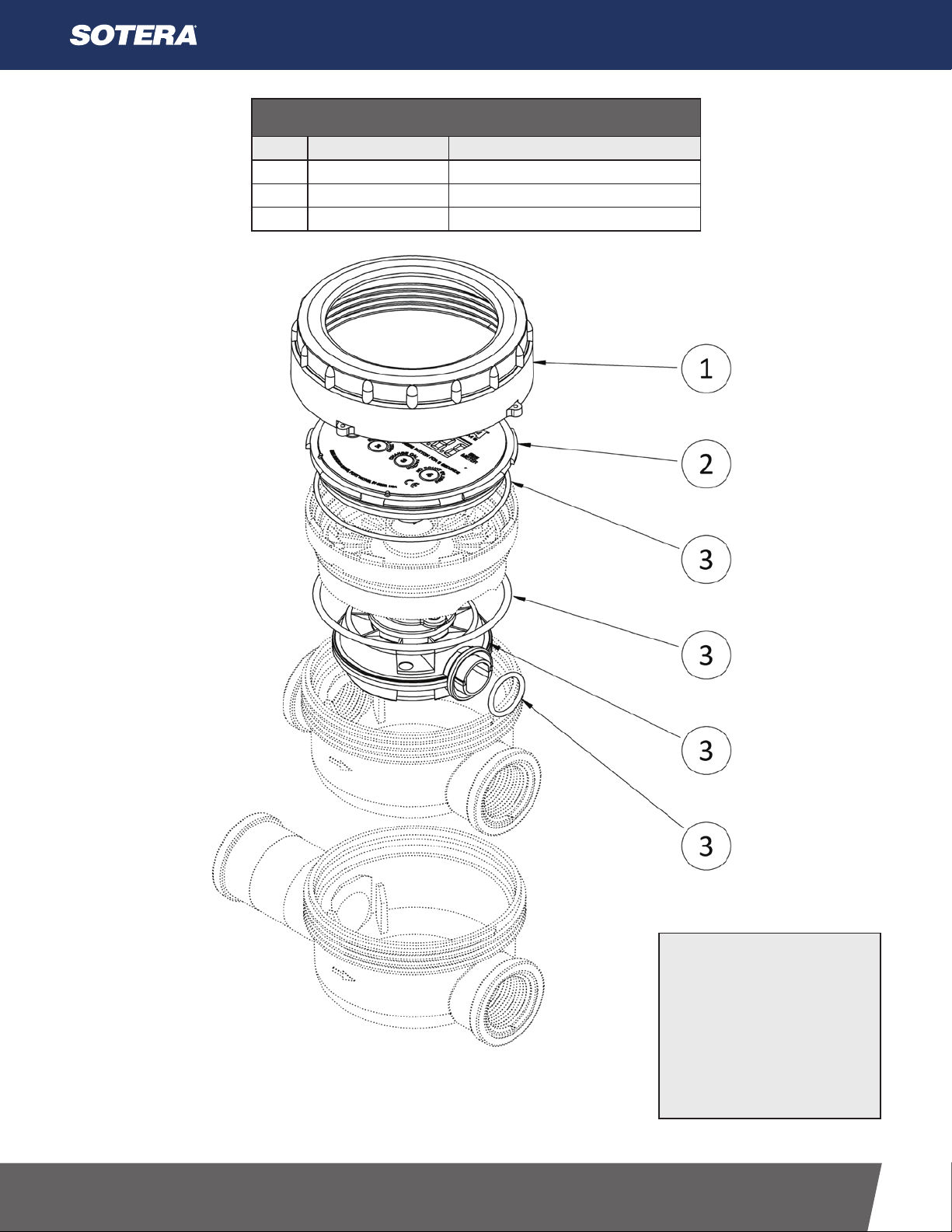

Technical Information

Materials of Construction

Body Polypropylene

Chamber Polyphenylene sulfide (PPS) and

303 Stainless Steel

Wetted Seals Fluorocarbon (EPDM optional)

Weather &

Dust Body Seal

BUNA-N

Display LCD (Liquid Crystal Display)

Power Two CR2032 Lithium batteries and external

5 - 24 VDC (see page 8)

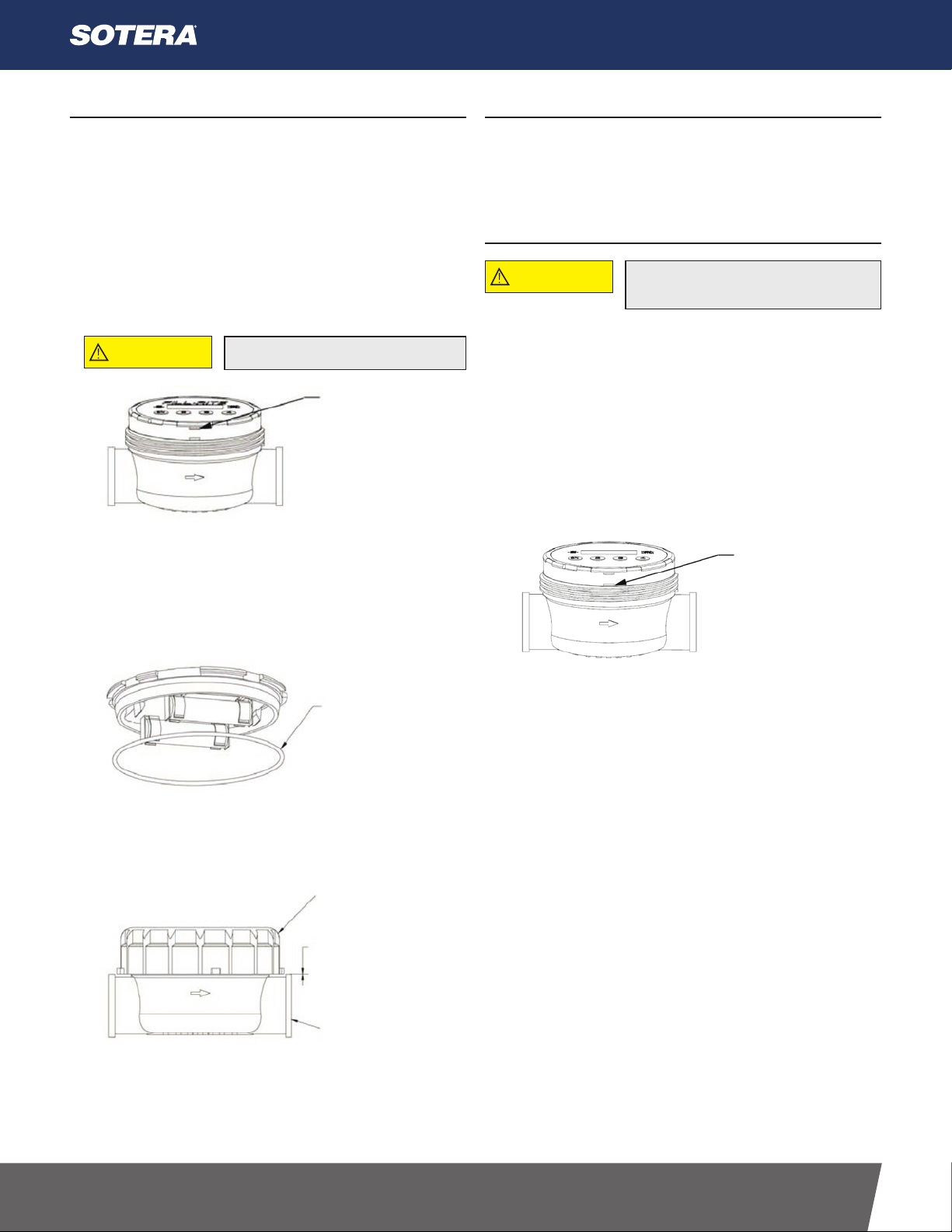

The 825 & 850 Digital Meters will handle most pesticides,

automotive fluids (except gasoline), and mild acids.

It is also compatible with the following fluids**:

Aatrex 4L®

Abate 4E®

Apron®

Agrotain®

Assure II®

Atrazine 4L

Banvel®

Banvel SFG®

Bicep®

Blazer®

Treflan®

Dual®

**Camix TM

Caustic Soda (50%)

Clarity®

Command®

Conclude®

Conclude®xtra

Contour

Diesel Fuel

Doubleplay®

Dual II®

Ethylene Glycol

Flexstar®

Fultime®

Fusion®

Gramoxone lnteon™

3.38EC Pursuit®

Rezult®

Roundup®

Squadron®

Surpass®

Superboll®

Touchdown®

Treflan™ HFP

** Requires EPDM Seals.

Aatrex®, Aatrex® 4L., Bicep®, Bicep 11®, Dual®, and Dual 11® are registered trademarks

of Syngenta Corporation. Broadstrike and Treflan are registered trademarks of Dow AgroSciences.

Banvef®, BanvelSGF®, Blazer®, camix, Clarity®, Conclude®, Galaxy®, Guardsman®, Lumax,

Manifest “Marksman® Poast®, Poast HC®, Poast Plus®. Rezult®, and Storm® are registered

trademarks of BASF. DoublePlay®, Eptam® 7E, FulTime, Fusion®, Gramaxone® Extra, Karate®,

ReHex®, Surpass®. TopNotch, and Touchdown® are registered trademarks of Syngenta.

Contour®.Detail, Pursuit®, Prowl®, and Squadron® are registered trademarks of American

Cyanimld. Harness® Xtra, Roundup® are registered trademarks of Monsanto Company.

Command®, and Furadan® are registered trademarks of FMC.Agrotain® Isa registered

trademark of IMCAgrico. Superboll®is a registered trademark of Griffin.

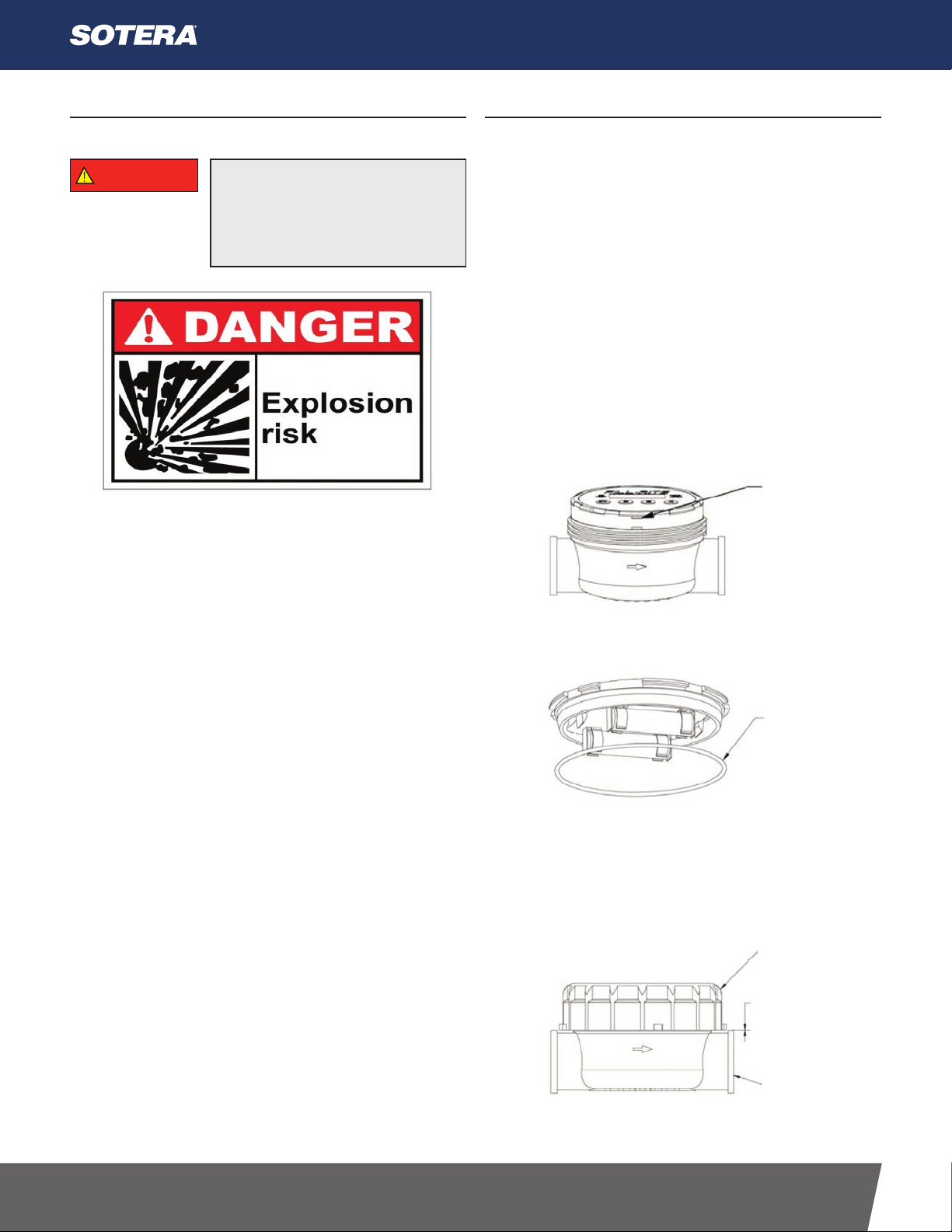

The 825P & 850P Digital Meters are NOT compatible with very strong

acids or if fluid flash point is below 100°F (38°C). If in doubt about

compatibility of a specific fluid, contact supplier of fluid to check for

any adverse reactions to the following wetted materials:

Guardsman®

Harness xtra®

Karate®

Laddock S-12®

Lasso Micro Tech®

*Lumax TM

Manifest™

Marksman®

Maxim®

Methyl Parathion Broadstrike®+

Motor Oil Broadstrike®+

Nufos®

Phosphoric Acid

Poast®

Poast HC®

3ME Poast Plus®

Princep 4L®

Prowl®

Detail™

Oil.Adend®

Dual®

Eptam 7E®

Fallowmaster®

Frontier®

Furadan®

Gramoxone Extra®

Prowl®

Reflex®

Ridomil Gold®

Sodium Hydroxide (50%)

Storm®

100 Surpass® EC

Topnotch®

Treflan™

Water

Fluid Compatibility