Preliminary Device Description HG G-19600ZA | English, Revision 02 | Date: 13.03.2018

3Table of Contents

Contents

1 About this Document ............................................................................. 5

1.1 Function................................................................................................................................. 5

1.2 Symbols ................................................................................................................................. 5

2 Introduction............................................................................................. 7

2.1 Range of Use ........................................................................................................................ 7

2.2 Qualification of the Users................................................................................................. 7

2.3 Intended Use ........................................................................................................................ 7

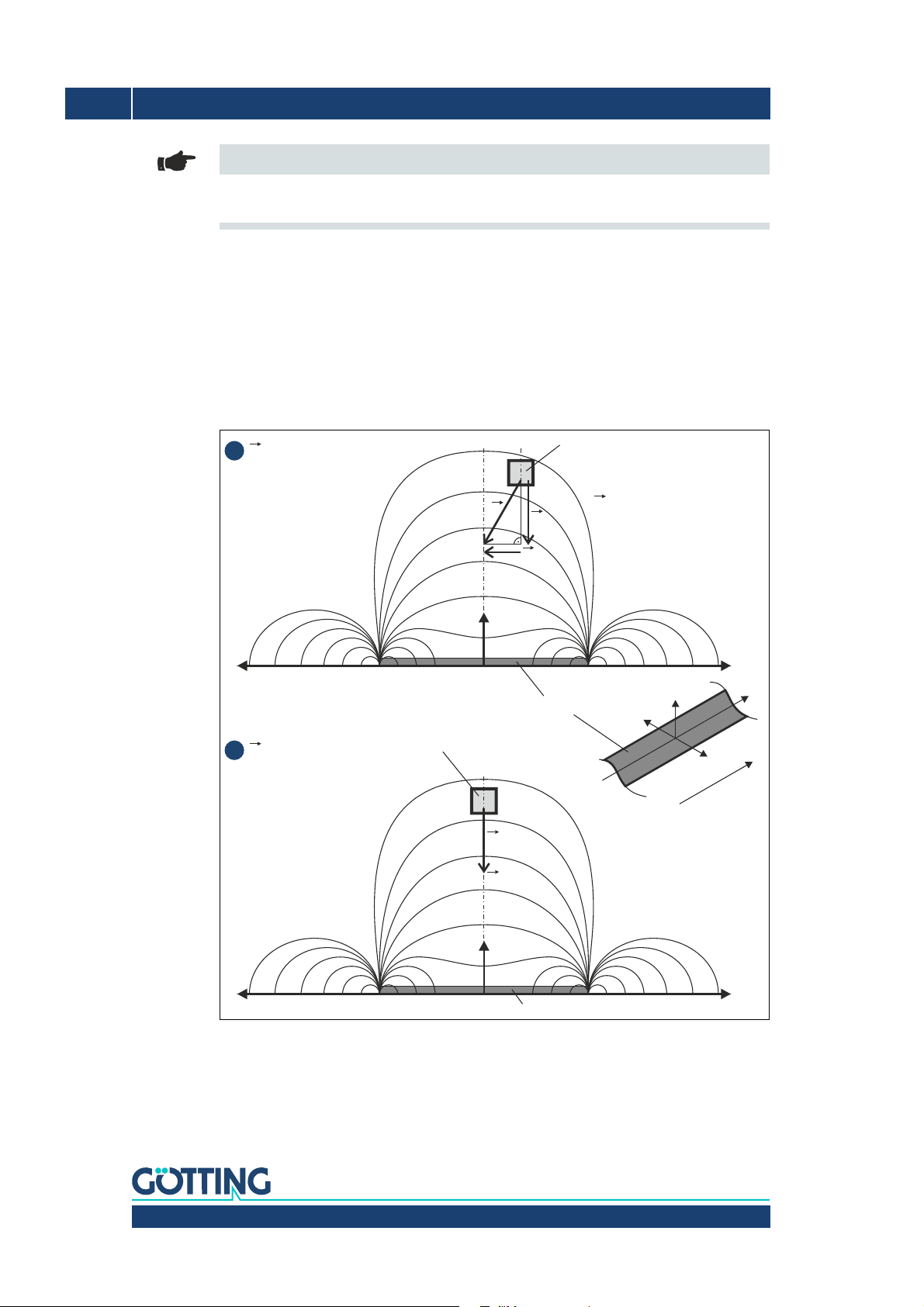

2.4 Functional Principle ........................................................................................................... 8

3 Mounting ............................................................................................... 10

3.1 Magnetic Tape ...................................................................................................................10

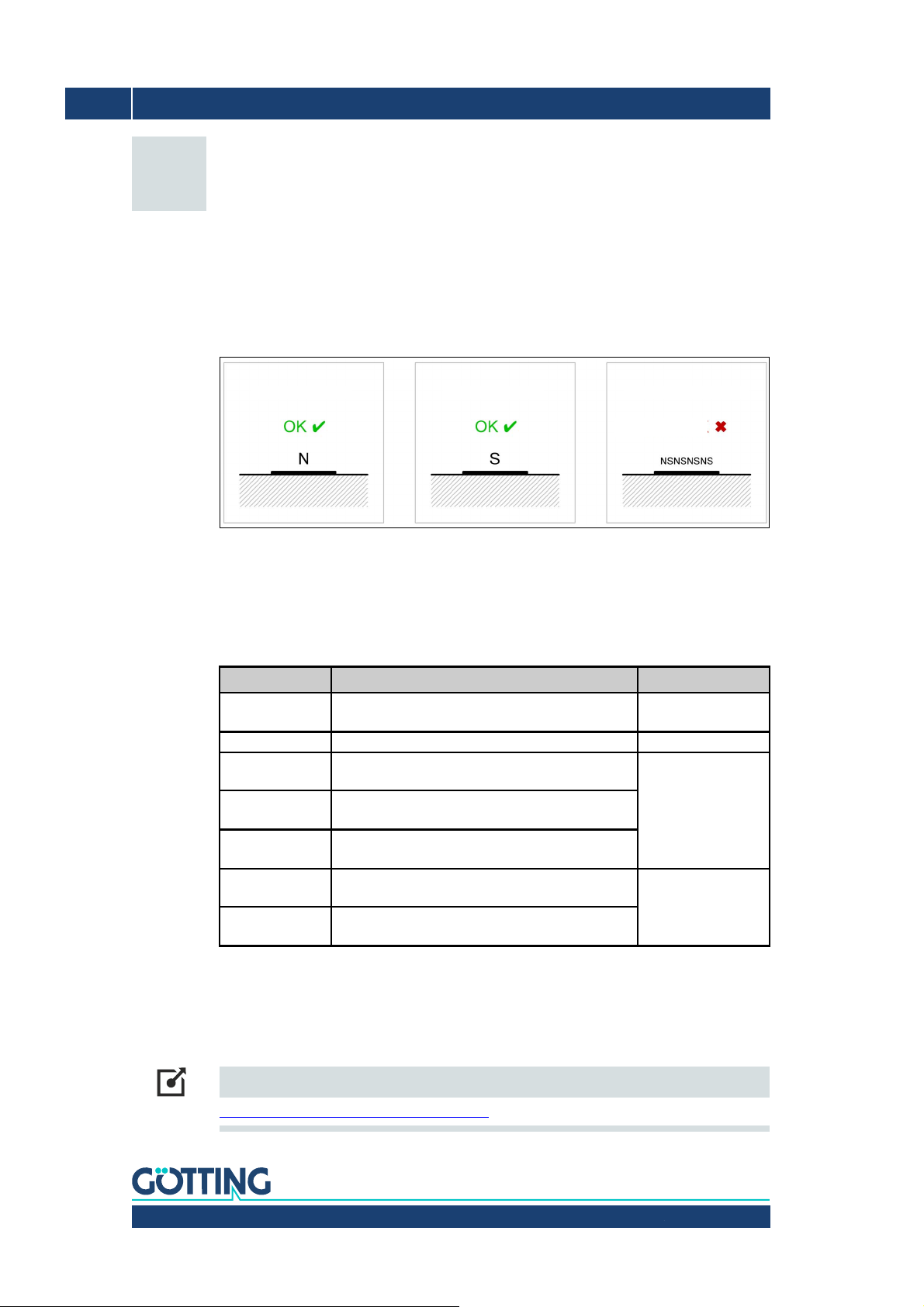

3.1.1 Magnetic Tape Types ...................................................................................................................10

3.1.2 Magnetic Tape Installation .........................................................................................................10

3.2 Magnet Sensor ..................................................................................................................11

3.2.1 Requirements..................................................................................................................................11

3.2.2 Mounting on the Vehicle .............................................................................................................12

3.2.3 Connection Cable (assembled on one side) ..........................................................................13

4 Commissioning ..................................................................................... 14

4.1 Configuration of the Magnet Sensor ..........................................................................14

4.2 Compensation of Permanent Magnetic Interferences ..........................................16

4.2.1 Compensation of Static Magnetic Interferences .................................................................17

4.2.2 Deleting the Compensation........................................................................................................17

4.3 Automatic Calibration of the Track Detection .........................................................18

5 Hardware ............................................................................................... 19

5.1 LEDs ......................................................................................................................................19

5.2 Pin Assignment .................................................................................................................20

5.2.1 ST 1 Service / Configuration ......................................................................................................20

5.2.2 ST 2 Operation................................................................................................................................20

5.2.3 Digital Inputs Turnoff Selection ................................................................................................21

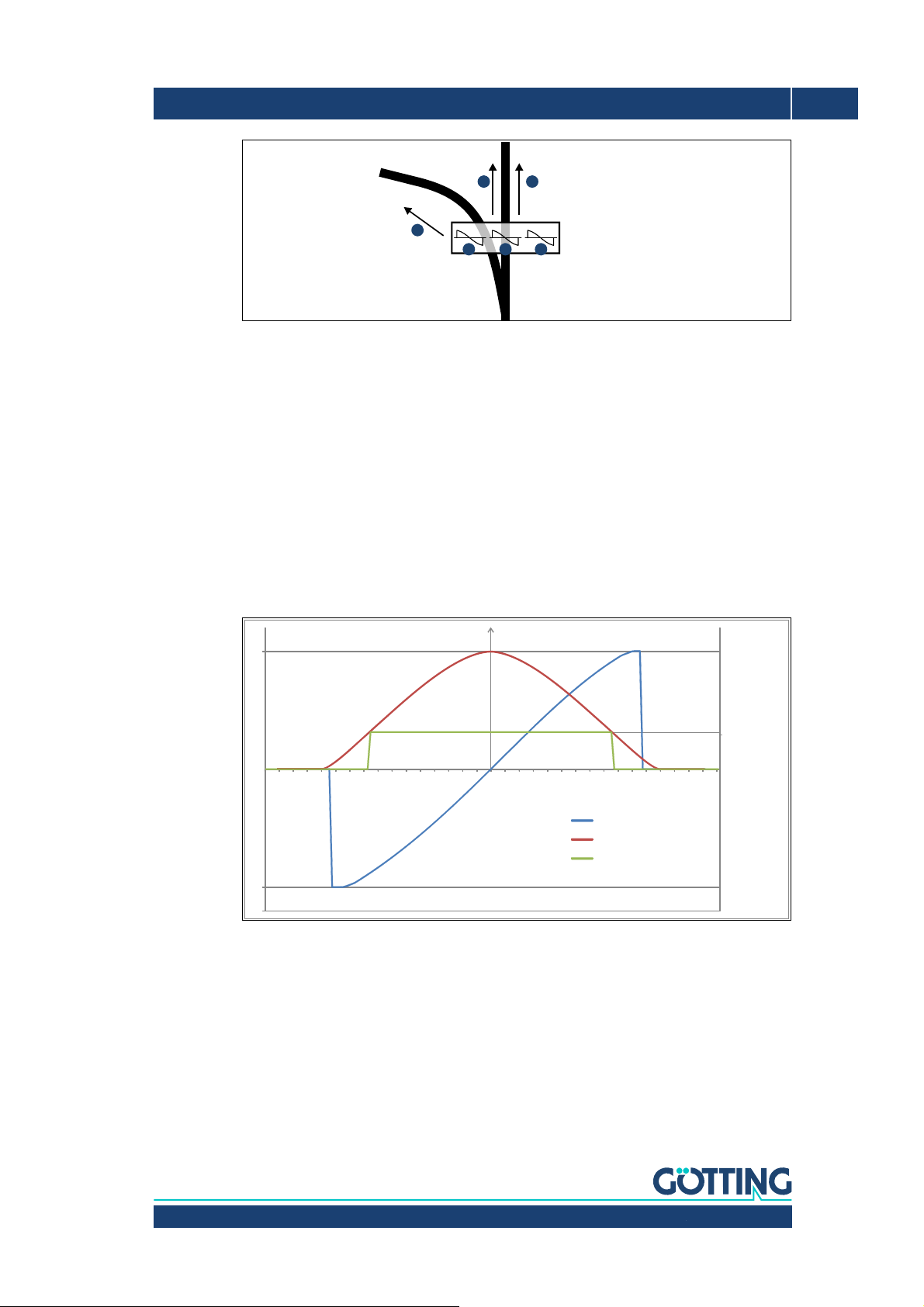

5.3 Turning off from the Main Track..................................................................................21

6 Software ................................................................................................22

6.1 Switch-On Behavior .........................................................................................................22

6.2 Connection to a PC via the Serial Interface .............................................................22

6.3 Terminal Program .............................................................................................................22

6.4 Service Program................................................................................................................23

6.4.1 (1) CSV Output................................................................................................................................24

6.4.2 (2) Settings ......................................................................................................................................26

6.4.3 (C) calibration settings .................................................................................................................27

6.4.4 (3) test monitor...............................................................................................................................28

6.4.5 (4) RAW data monitor...................................................................................................................29

6.4.6 Software Update (Firmware)......................................................................................................30

7 Maintenance.......................................................................................... 31