Device Description HG G-19370-B/HG G-19380-B | English, Revision 03 | Date: 05.05.2020

3

Table of Contents

Contents

1 About this Document........................................................................ 5

1.1 Function ................................................................................................................................... 5

1.2 Presentation of Information .............................................................................................. 5

1.2.1 Warning Notices ............................................................................................................... 5

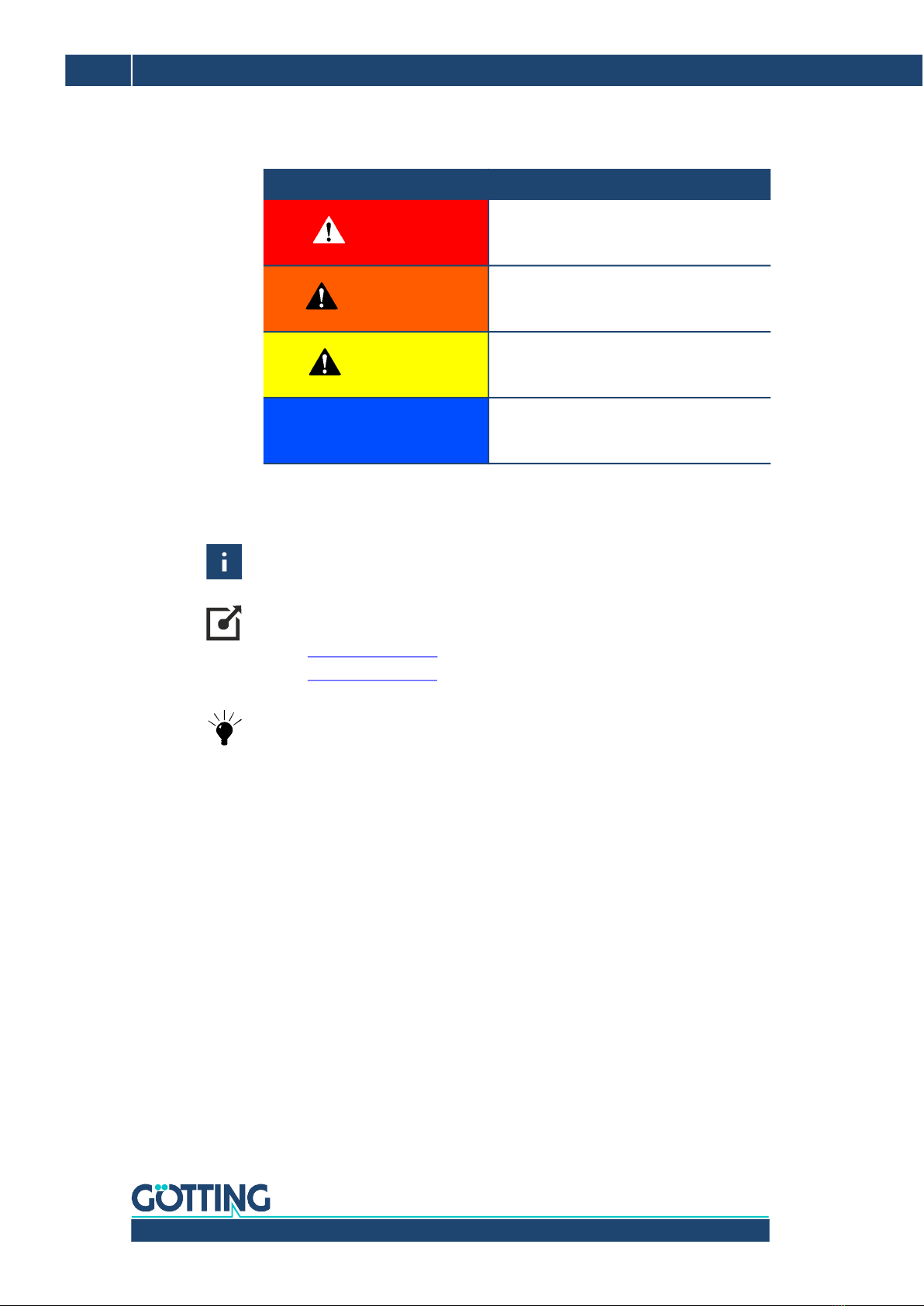

1.2.2 Symbols ............................................................................................................................... 6

2 Introduction....................................................................................... 7

2.1 Variants/Versions .................................................................................................................. 7

2.2 Range of Use .......................................................................................................................... 7

2.3 Qualification of the Users ................................................................................................... 8

2.4 Intended Use .......................................................................................................................... 8

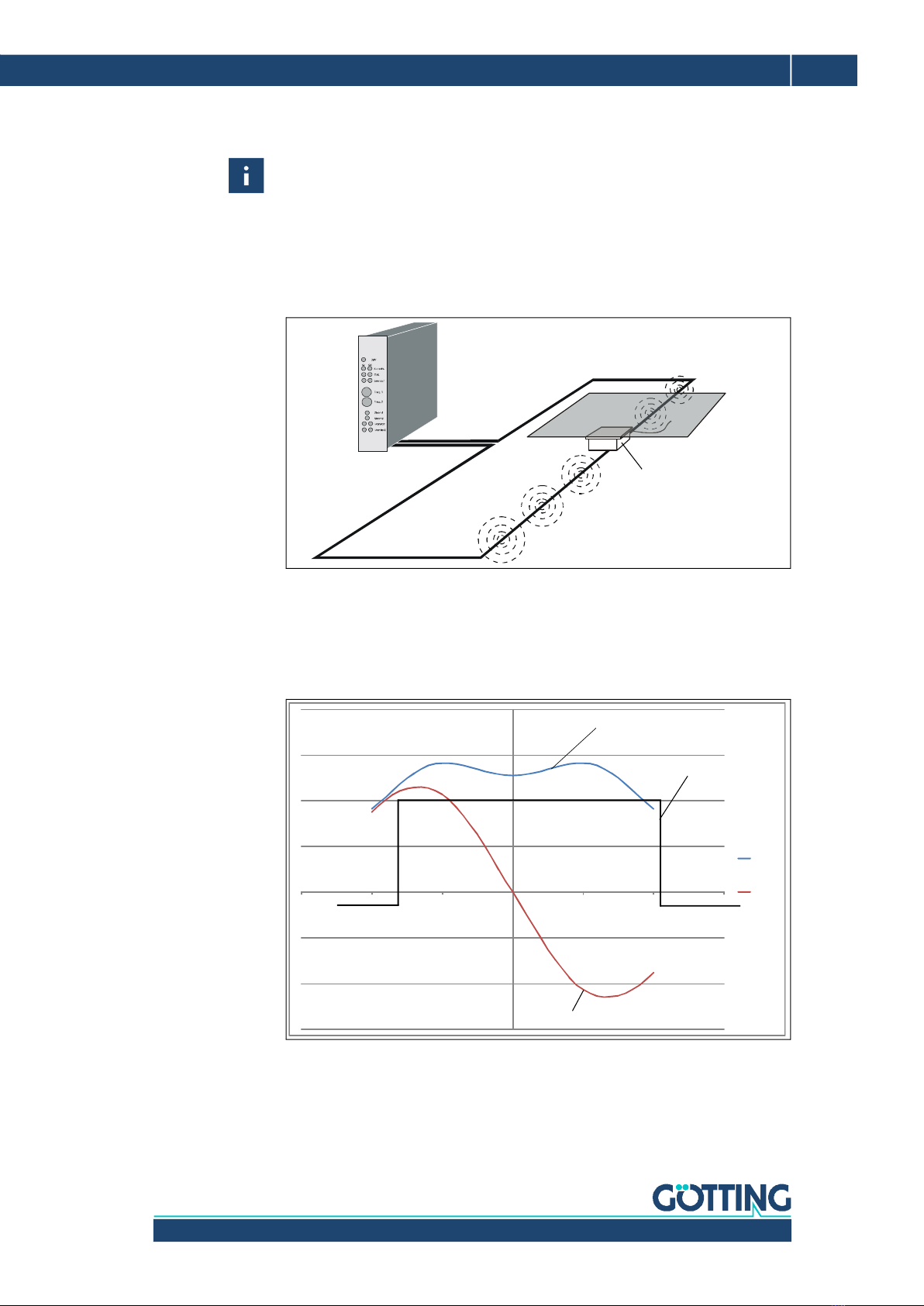

2.5 Functional Principle ............................................................................................................. 9

3 Mounting ......................................................................................... 11

3.1 Guide Wire ............................................................................................................................11

3.2 Energy Track.........................................................................................................................11

3.3 Inductive Guidance Sensor .............................................................................................. 11

3.3.1 Requirements ..................................................................................................................11

3.3.2 Mounting on the Vehicle ..............................................................................................11

3.3.3 Connection Cables (assembled on one side) / Terminating Resistors...........12

4 Commissioning ............................................................................... 14

5 Hardware ......................................................................................... 15

5.1 HG G-19370ZB/HG G-19380ZB (CAN Bus).................................................................15

5.1.1 LEDs....................................................................................................................................15

5.1.2 Pin Assignment ...............................................................................................................15

5.1.2.1 ST 1 ................................................................................................................................16

5.1.2.2 ST 2 / ST 3 (CAN 1 / CAN 2) ................................................................................... 16

5.2 HG G-19370YB/HG G-19380YB (Profinet) .................................................................. 17

5.2.1 LEDs....................................................................................................................................17

5.2.2 Pin Assignment ...............................................................................................................17

5.2.2.1 ST 1 ................................................................................................................................18

5.2.2.2 ST 2 / ST 3 (BUS 1 / BUS 2).................................................................................... 18

6 Configuration .................................................................................. 19

6.1 Turn-On Characteristic......................................................................................................19

6.2 Connection to a PC via the USB Interface ..................................................................19

6.3 Terminal Program ...............................................................................................................19

6.4 Service Program..................................................................................................................20

6.4.1 Main Menu........................................................................................................................20

6.4.1.1 HG G-19370/80ZB (CAN)......................................................................................... 20

6.4.1.2 HG G-19370/80YB (Profinet) ..................................................................................20

6.4.2 (1) Frequency Config .....................................................................................................21

6.4.3 (2) Calibration Config ....................................................................................................21

6.4.4 (3) Encoder Config .........................................................................................................22

6.4.5 (4) CSV ...............................................................................................................................23

6.4.6 HG G-19370ZB/HG G-19380ZB: (5) CAN Config .................................................. 24

6.4.7 Firmware Update ............................................................................................................24

7 CAN Bus Communication (HG G-19370ZB/HG G-19380ZB) ........ 26

7.1 Telegrams..............................................................................................................................26

7.2 Control and Status Telegrams ........................................................................................27

7.2.1 Incoming Telegram (IN) ................................................................................................ 27

7.2.2 Outgoing Telegram OUT1 ............................................................................................28