Device Description HG G-193x0-B | English, Revision 02 | Date: 07.05.2018

3Table of Contents

Contents

1 About this Document ............................................................................. 5

1.1 Function................................................................................................................................. 5

1.2 Symbols ................................................................................................................................. 5

2 Introduction............................................................................................. 7

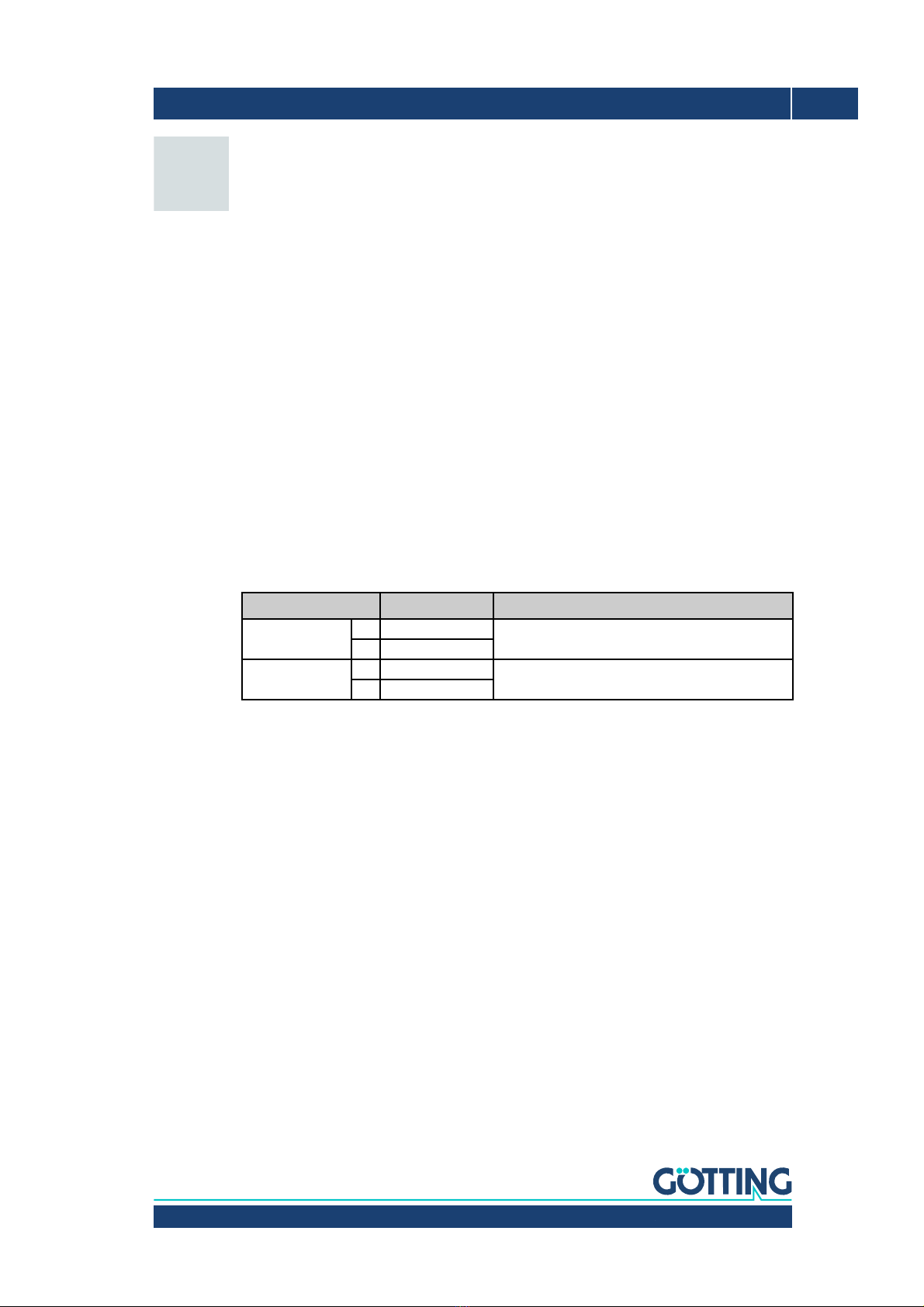

2.1 Variants/Versions ................................................................................................................ 7

2.2 Range of Use ........................................................................................................................ 7

2.3 Qualification of the Users................................................................................................. 8

2.4 Intended Use ........................................................................................................................ 8

2.5 Functional Principle ........................................................................................................... 9

3 Mounting ............................................................................................... 11

3.1 Guide Wire ..........................................................................................................................11

3.2 Energy Track ......................................................................................................................11

3.3 Inductive Guidance Sensor ............................................................................................11

3.3.1 Requirements..................................................................................................................................11

3.3.2 Mounting on the Vehicle .............................................................................................................12

3.3.3 Connection Cables (assembled on one side) / Terminating Resistors..........................13

4 Commissioning ..................................................................................... 14

5 Hardware ............................................................................................... 15

5.1 HG G-193x0ZB (CAN Bus)..............................................................................................15

5.1.1 LEDs...................................................................................................................................................15

5.1.2 Pin Assignment ..............................................................................................................................15

5.1.2.1 ST 1 ................................................................................................................................................16

5.1.2.2 ST 2 / ST 3 (CAN 1 / CAN 2) ...................................................................................................16

5.2 HG G-193x0YB (Profinet) ...............................................................................................17

5.2.1 LEDs...................................................................................................................................................17

5.2.2 Pin Assignment ..............................................................................................................................17

5.2.2.1 ST 1 ................................................................................................................................................18

5.2.2.2 ST 2 / ST 3 (BUS 1 / BUS 2)....................................................................................................18

6 Configuration ........................................................................................ 19

6.1 Turn-On Characteristic....................................................................................................19

6.2 Connection to a PC via the USB Interface ................................................................19

6.3 Terminal Program .............................................................................................................19

6.4 Service Program................................................................................................................20

6.4.1 Main Menu .......................................................................................................................................20

6.4.1.1 HG G-193x0ZB (CAN) ...............................................................................................................20

6.4.1.2 HG G-193x0YB (Profinet).........................................................................................................20

6.4.2 (1) Frequency Config ....................................................................................................................21

6.4.3 (2) Calibration Config ...................................................................................................................21

6.4.4 (3) Encoder Config ........................................................................................................................22

6.4.5 (4) CSV ..............................................................................................................................................23

6.4.6 HG G-193x0ZB: (5) CAN Config ................................................................................................24

6.4.7 Firmware Update ...........................................................................................................................24