TESTING 1.0290 User manual

TESTING Bluhm & Feuerherdt GmbH

Production and Distribution of

Systems for the Testing of Construction Materials

Motzener Str.26b

DE –12277 Berlin

Tel. [+49 30] 7109645-0

Fax: [+49 30] 7109645-98

1

Operating Manual

Electronic Blaine Air-Permeability Apparatus

for determining the fineness of cement

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

2

Importance of this Operating Manual:

Warning: It is expected that Users and Operators read and understand this entire Oper-

ating Manual before putting the system into operation. Reading and understanding this

entire Operating Manual is absolutely necessary before operating the system.

Contents Page no.:

1. General information.............................................................................................3

1.1 Manufacturer’s designation .................................................................................3

1.2 Purpose for which this system has been designed..............................................3

1.3 Conditions under which this system may NOT be used ......................................4

1.4 Guarantee ...........................................................................................................4

1.5 Basic safety instructions......................................................................................5

1.6 Acceptance of the product and transport.............................................................6

1.6.1 Acceptance of the product............................................................................6

1.6.2 Transport ......................................................................................................7

1.7 Scope of delivery.................................................................................................7

1.8 Instructions for electrical connection....................................................................8

2. Characteristics of the apparatus ........................................................................9

2.1 Basic structural design ........................................................................................9

2.2 Technical data.....................................................................................................9

3. Placing the Apparatus into operation ..............................................................10

4. How to conduct the test ....................................................................................11

5. Checking and maintenance...............................................................................12

6. Troubleshooting.................................................................................................13

7. Shutting down the system for lengthy periods...............................................14

8. Scrapping ...........................................................................................................14

9. Spare parts and services...................................................................................15

9.1 Date of issue of this Operating Manual:.............................................................15

9.2 Copyright...........................................................................................................15

9.3 Address for technical support and spare-parts ordering....................................15

10. Spare-Parts List .................................................Fehler! Textmarke nicht definiert.

Attachments:

Declaration of conformity

Record of measurement and testing at the manufacturer’s plant

Safety Data Sheet

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

3

1. General information

1.1 Manufacturer’s designation

Manufacturer’s designation:

Blaine Apparatus (please see the cover page of this

Operating Manual)

Designation of the model itself:

Please see the nameplate (rating plate) on the unit.

It provides all the characteristics and the electrical

rating data.

1.2 Purpose for which this system has been designed

This Operating Manual contains the information required for operation of the products de-

scribed here, for the purpose for which they have been designed. This Operating Manual

is intended to be used only by technically qualified staff.

“Technically qualified staff” is defined as those persons who – as a result of their training;

their experience; the instructions which they have received; as well as their knowledge of

the relevant standards, regulations, accident-prevention regulations, and conditions of

product operation in the company –have been authorized by the person responsible for

the safety of the company facilities to carry out the activities and actions required for op-

eration of the equipment described below, and who can recognize and prevent any possi-

ble dangers arising from such operation (this definition of technically qualified staff has

been provided in IEC 364).

The User must by all means observe the requirements and limit values, as well as all

safety instructions, given in this Operating Manual. Anyuse of this device not in conformity

with these stipulations shall be considered tobe in violation of the use for which this system

was intended. If this device must be operated under special conditions, or with special

modes of operation, then this shall be authorized only after consultation with the Manufac-

turer, and after obtaining his prior and express approval.

The fineness of grind can be determined according to the Blaine technique and is indicated

as the specific surface (Blaine value). The semiautomatic apparatus serves exclusively for

determination of the specific surface of powders, and for fast analysis of characteristic

operational values. The Blaine value is not a measure of granulometric distribution. The

Blaine value can therefore be used only to a limited degree to evaluate the suitability of a

type of test material for a certain use.

Caution

The instructions given in this Operating Manual apply only for the cor-

rect application of the apparatus. In order to correctly conduct tests, the

User and Operator must observe the specific standards that apply for

the testing being conducted.

Please take the time to read this Operating Manual carefully. It describes how you safely

operate the machine.

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

4

Please keep this Operating Manual to hand at all times, during the entire life cycle of this

apparatus. Please refer to it whenever you have a question on the operation of this appa-

ratus.

The Manufacturer cannot accept any responsibility for any damages that occur owing to

false use of this apparatus.

This operating manual contains safety instructions that are to be observed in order to ex-

clude any risk of fatalities, injuries, damage to the equipment or improper operation. Safety

markings are as follows:

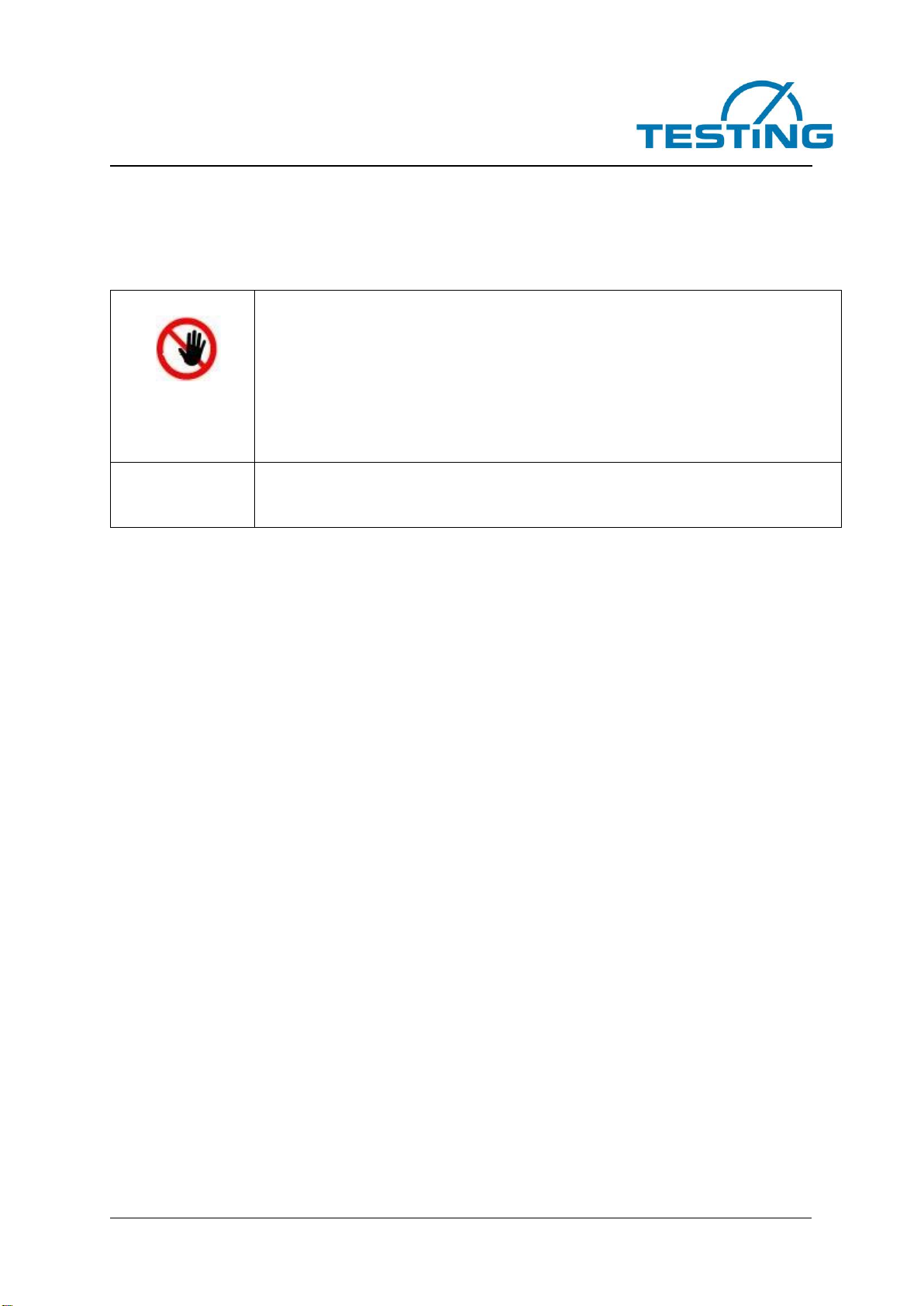

Caution

This warning refers to dangers that could cause material damage.

Danger

This warning refers to dangers that could cause severe injuries or even

fatalities.

Note

Provides practical advice on operation

1.3 Conditions under which this system may NOT be used

This Blaine Apparatus was not intended for use under the following conditions or with the

following actions being taken. It may therefore NOT be used under such conditions or in

connection with the following actions:

Do not disassemble this system. Do not try to repair it or to modify it.

Operate this product only with a mains electrical system which satisfies the ratings

for voltage and current as given in this Operating Manual.

The apparatus may not be operated in locations which are subject to the following

conditions or substances: Ice formation, Heat radiation, Formation of condensation

water, Dust, Corrosive gases, Vibrations, Severe physical impact (jolts), High rela-

tive humidity, Excessive temperature fluctuations

Do not tamper with the liquid in the manometer. As recommended in the relevant

standard. This liquid can cause serious health.

1.4 Guarantee

Our General Terms of Sales and Delivery apply in all cases.

The Manufacturer guarantees that this Operating Manual has been prepared in conformity

with the technical and functional parameters of the Blaine Apparatus as delivered. The

Manufacturer reserves the right to add supplementary information to this Operating Man-

ual as required.

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

5

The guarantee provided by the Manufacturer is the legal guarantee. This guarantee does

not cover wear-and-tear parts.

The Manufacturer guarantees trouble-free operation only if the User observes the instruc-

tions in this Operating Manual, and only if the User employs the Blaine Apparatus for the

purpose for which it is intended.

The Manufacturer cannot be held liable for damages that may occur if the Blaine Appa-

ratus is used for purposes for which it is not intended, or if the User does not observe the

instructions and rules for operation as set forth in this Operating Manual.

No claims for damages may be lodged against the Manufacturer if the Blaine Apparatus

is modified in its structural or constructional characteristics without the prior written con-

sent of the Manufacturer, or if its functional characteristics are modified without such con-

sent.

Any person acting in violation of the above stipulations may be prosecuted before a court

of law.

1.5 Basic safety instructions

Only those persons may be permitted to operate the Electronic Blaine Air-Permeability

Apparatus alone (i.e., without supervision) who have met all of the following criteria:

Persons who are at least eighteen (18) years of age, and

Persons who have been instructed in the operation of the Blaine Apparatus, and

In the operation of the Blaine Apparatus, the person operating the instrument must take

every precaution to ensure that he/she does not injure himself / herself or any other per-

sons. Only those persons may be permitted to operate the Blaine Apparatus who have

been instructed in its proper use.

If any malfunction, damage, or other trouble is determined on the Blaine Apparatus, and if

its faulty condition endangers its operational safety, then the apparatus must be immedi-

ately taken out of operation. It may be put back into operation only after all sources of

danger have been eliminated.

Check to make sure that the ratings given on the nameplate (rating plate) on the unitmatch

those of the actual voltage supplied by the mains power.

The Blaine Apparatus may be used only for the purposes described here. Any use of the

apparatus in a manner not intended or described here will result in loss of guarantee pro-

tection.

This Blaine Apparatus has been designed and built in accordance with the state of the

engineering art and with the accepted rules of good engineering practice. The use of this

Blaine Apparatus, however, can result in danger to life and limb of the Users and third

parties, and can cause damage to mechanical-engineering parts and other items of prop-

erty.

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

6

If there are any malfunctions or other trouble that could cause dangerous situations to

arise in work with the Blaine Apparatus, these difficulties must be immediately corrected

before working with the machine.

Danger

The mixing of cement with water causes the release of alkaline sub-

stances. In working with concrete, it is essential to take all necessary

precautions to prevent dry cement from entering the eyes, mouth, or

nose. Use protective clothing to prevent skin contact with wet cement

or concrete. If cement or concrete enters the eyes, immediately and

carefully wash out the eyes with clean water. Seek medical help without

delay. If moist concrete comes into contact with the skin, wash it off

immediately.

The liquid in the manometer is, as recommended in the relevant stand-

ard. This liquid can cause serious health.

Please read the attachments for further information.

The manufacturer strongly recommends to carefully observe the following: all instructions

and procedure descriptions given in this Operating Manual; all applicable safety directives,

guidelines, and regulations; and all general rules for workplace environments.

The Operator must ensure that the personnel wear the respectively required protective

clothing, such as:

Safety boots

Suitable clothing

Protective gloves

Working clothing must be appropriate and not hinder the operatives in their work.

If need respiratory protection

1.6 Acceptance of the product and transport

1.6.1 Acceptance of the product

When accepting delivery of the product, first inspect it for its outer, visible condition. If this

inspection is satisfactory, the machine may be accepted from the freight forwarder (pack-

age service, courier, or other forwarding business).

If there are no shortcomings, and if there are no transport damages, then use the bill of

delivery to make sure that the consignment is complete, and that all parts have been de-

livered.

If you assume or suspect transport damage, or if transport damage becomes apparent

only after you have accepted the delivery, immediately make an exact report of the condi-

tions and any damage as they exist. Send us this report immediately by fax or e-mail.

Important: Absolutely do not make any changes to the delivered goods.

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

7

After we have studied your report, we can make a decision whether we can correct the

difficulties by one of the following options:

Deliver spare parts to you, or

Send a specialized fitter/installer to your plant, or

Ask that you return the system to us for repair.

1.6.2 Transport

This device will be delivered in the appropriate cardboard boxes. In order to prevent

transport damage, the remaining hollow spaces in the interior of the boxes will be filled

with bulk material.

This system can be moved by hand to the point at which it is to be operated. Its weight is

approx. 4 kg.

After you have unpacked the device, make a visual inspection to determine whether it was

damaged during transport. In cases of doubt, in which you believe the machine may have

been damaged, do not connect it, and get in touch with your dealer or sales person.

1.7 Scope of delivery

1 ea. Air Permeability Tester, including power cable, measuring cell with piston,

and sieve plates

1 ea. Brush

1 ea. Funnel

50 ml Filling oil for manometer

1 ea. Cone grease

1 ea. Injection unit with hose for filling

1 unit Round filter, ø 12.8 mm

1 ea. Digital thermometer

1 ea. Cone rubber stopper

Official calibration (only model 1.0290E)

Optional:

1 bottle Calibration sand, coarse

1 bottle Calibration sand, fine

Official calibration

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

8

Note

When the Electronic Blaine Air-Permeability Apparatus is delivered, it

is NOT calibrated.

If the customer requires, we can deliver the instrument with official cal-

ibration: as an option, for an additional price.

Important: do not place the Electronic Blaine Air-Permeability Appa-

ratus into operation before it has been properly calibrated.

1.8 Instructions for electrical connection

Danger

The electrical connections must be made by properly qualified electri-

cians.

Before making the power connections, make sure that your power sup-

ply is in accordance with the required power and frequency ratings

given in these instructions and on the equipment rating plate.

The power plug must have a safety device (an overcurrent trip) that

protects the system against overcurrent. This device must match the

machine voltage, and must be in accordance with the valid regulations.

The technical characteristics of this safety device must satisfy the reg-

ulations of the standards that apply in the country in which the machine

is being installed.

Caution

The Manufacturer cannot be held liable for any damage that takes

place because the above instructions are not followed.

Electrical tolerances:

Actual voltage: 10% of the rated voltage

Frequency: 1% of the rated frequency, on a continual basis; 2% of the rated fre-

quency, on a short-term basis

The power supply may not be interrupted for longer than 3 ms, and may not be set to zero.

Not more than 1 s may lapse between two power outages (cuts).

The power outages (cuts) may not exceed 20% of the voltage peak for more than one

cycle. Not more than 1 s may elapse between two power cuts.

The manufacturer cannot be held liable for damages to persons or property that arise

because the above instructions have not been observed.

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

9

2. Characteristics of the apparatus

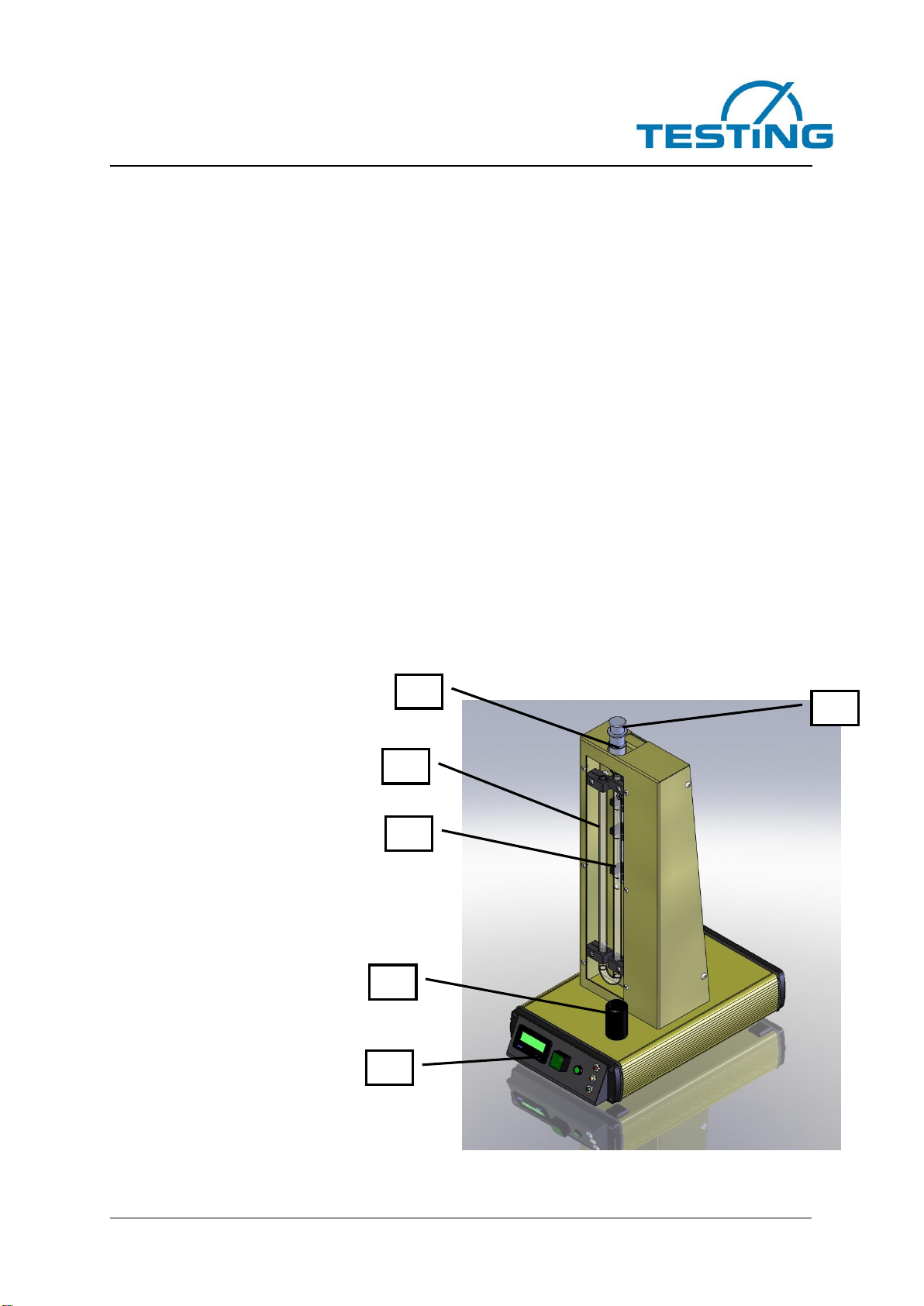

2.1 Basic structural design

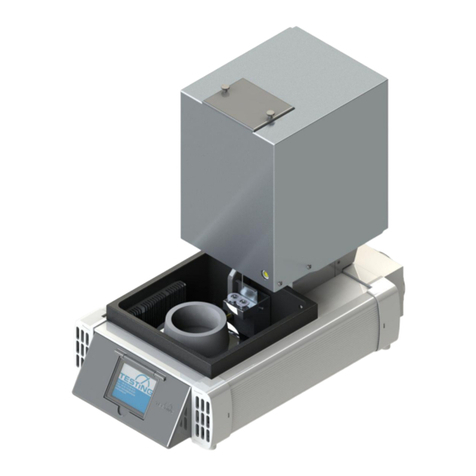

The measuring apparatus is mounted on a stable metal plate. A sturdy metal enclosure

on the left side of the apparatus contains the U-shaped manometer tube. The User can

observe the level of the manometer fluid through a window.

You can stop the testing procedure at any time by turning off the mains power switch. The

power connection is provided by a separate power cable with a two-pole and earthing-pin

plug.

The Manufacturer tests the function and liquid tightness of the apparatus before delivery.

2.2 Technical data

Power rating: 110-230 V / 50-60 Hz

Dimensions of the Apparatus: 175 mm wide x 300 mm deep x 450 mm high

Weight: 4 kg

Precision of the time measurement: 0.1 s

Class of enclosure protection: IP-55

Cell size according EN 196-6

V=approx. 1900mm³

Ø=12,7mm±1

H=15mm±1

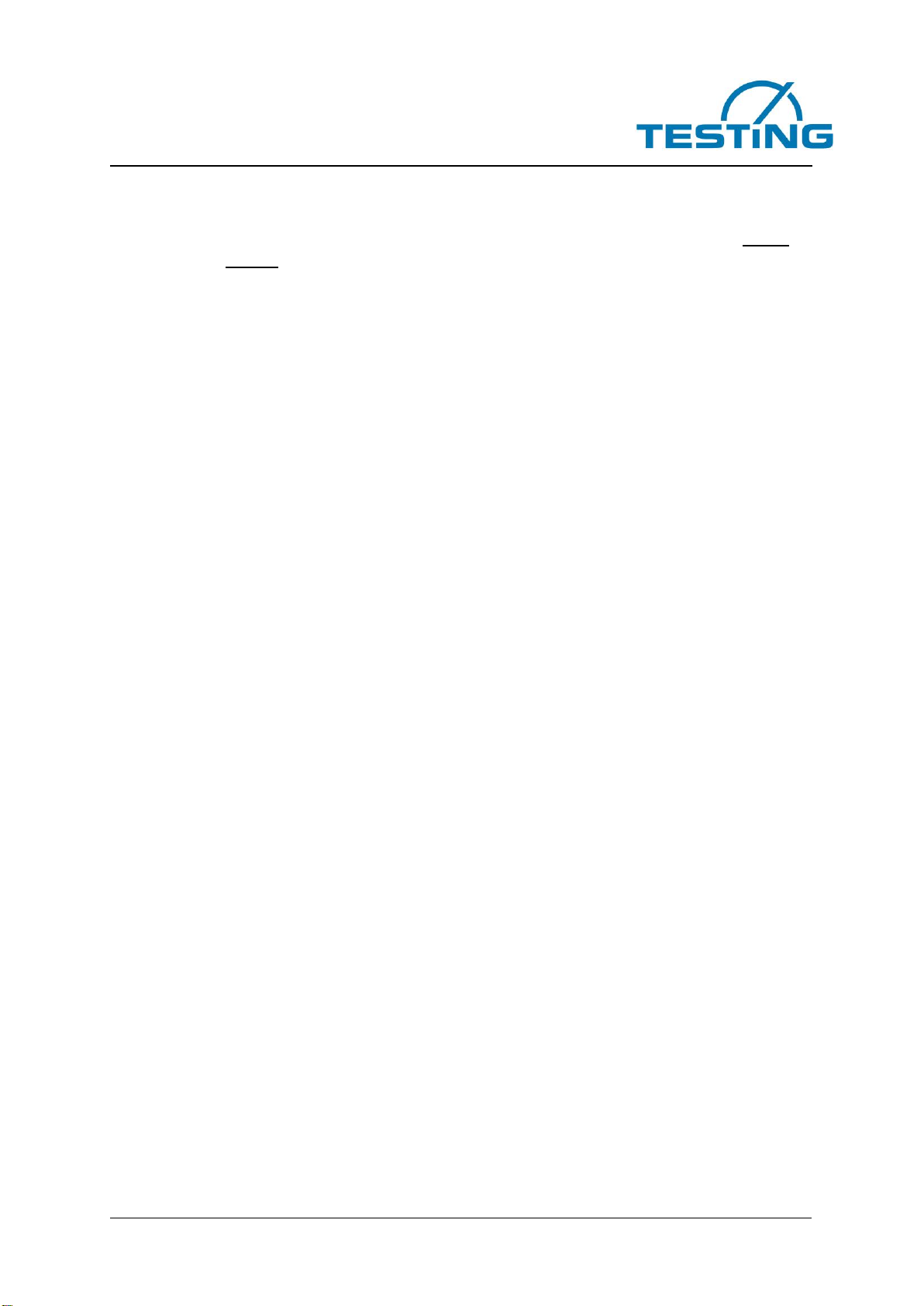

1- Opening to fill the

manometer liquid

2- U- shaped tube

3- Measuring section with

photoelectric barrier

4- Measuring cell with

piston and sieve plates

5- Connection support

6- operators interface

Rear side:

Power switch

1

3

2

4

5

6

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

10

3. Placing the Apparatus into operation

Set up the Blaine Apparatus on a surface that is level, that is not subject to vibrations, and

that can sufficiently support the weight of the apparatus. The permissible ambient condi-

tions are in accordance with standard laboratory conditions as set forth in EN 196

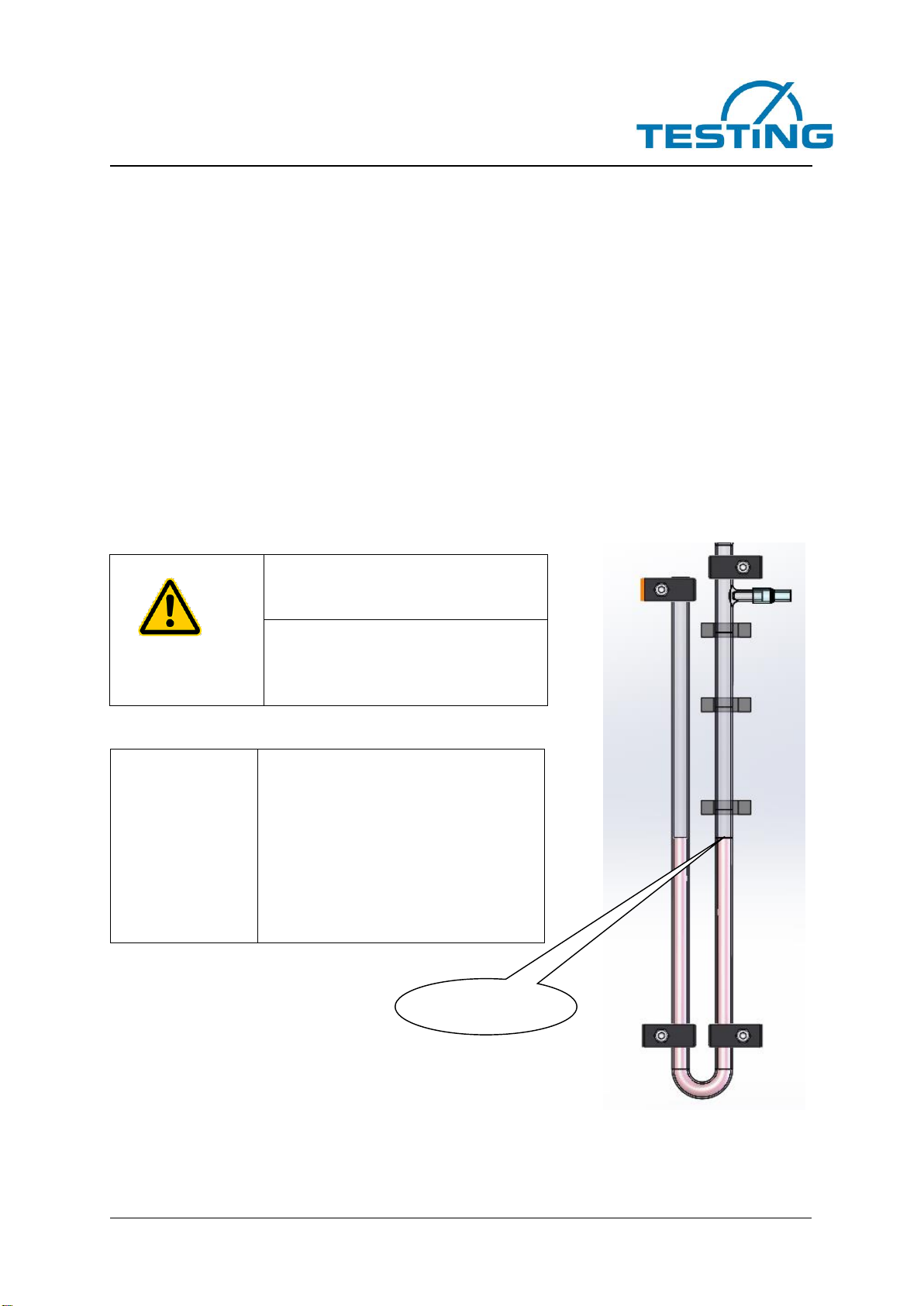

Use the injection with hose, supplied by the Manufacturer, to pour the filling oil into the U-

shaped tube. Before filling the tube, make sure that it is clean and dry.

Use the injection unit to remove liquid from the bottle in which it is delivered. Insert the end

of the injector hose into the U-shaped tube. Make sure that you can see the hose in the

U-shaped tube, and also make sure that the manometer liquid actually flows into the tube.

Fill the liquid up to the lowest mark.

If the liquid is filled above the proper filling height, use the injector unit to remove the

surplus oil.

Grease the cone slightly with the delivered grease.

Caution

The manometer liquid is a min-

eral hydraulic oil. This liquid can

cause serious health.

Do not pour out the oil throuht

the cone.

It could go to a valve and could

cause damage.

Note

Fill the oil slowly and carefully,

since the levels of the oil will ad-

just very slowly.

If exceed the mark then use the

injection with tube to suck out the

surplus oil.

At regular intervals, the liquid

level must be checked. The fluid

level must be equal to the mark.

Filling height

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

11

4. How to conduct the test

1 Prepare the powder bed in accordance with the instructions given in DIN 196-6.

2 Place a thin coat of cone grease on the cone. Then insert the measuring cell into

the opening of the U-shaped tube that is provided for the cell.

3 Be careful not to disturb the powder bed in your work.

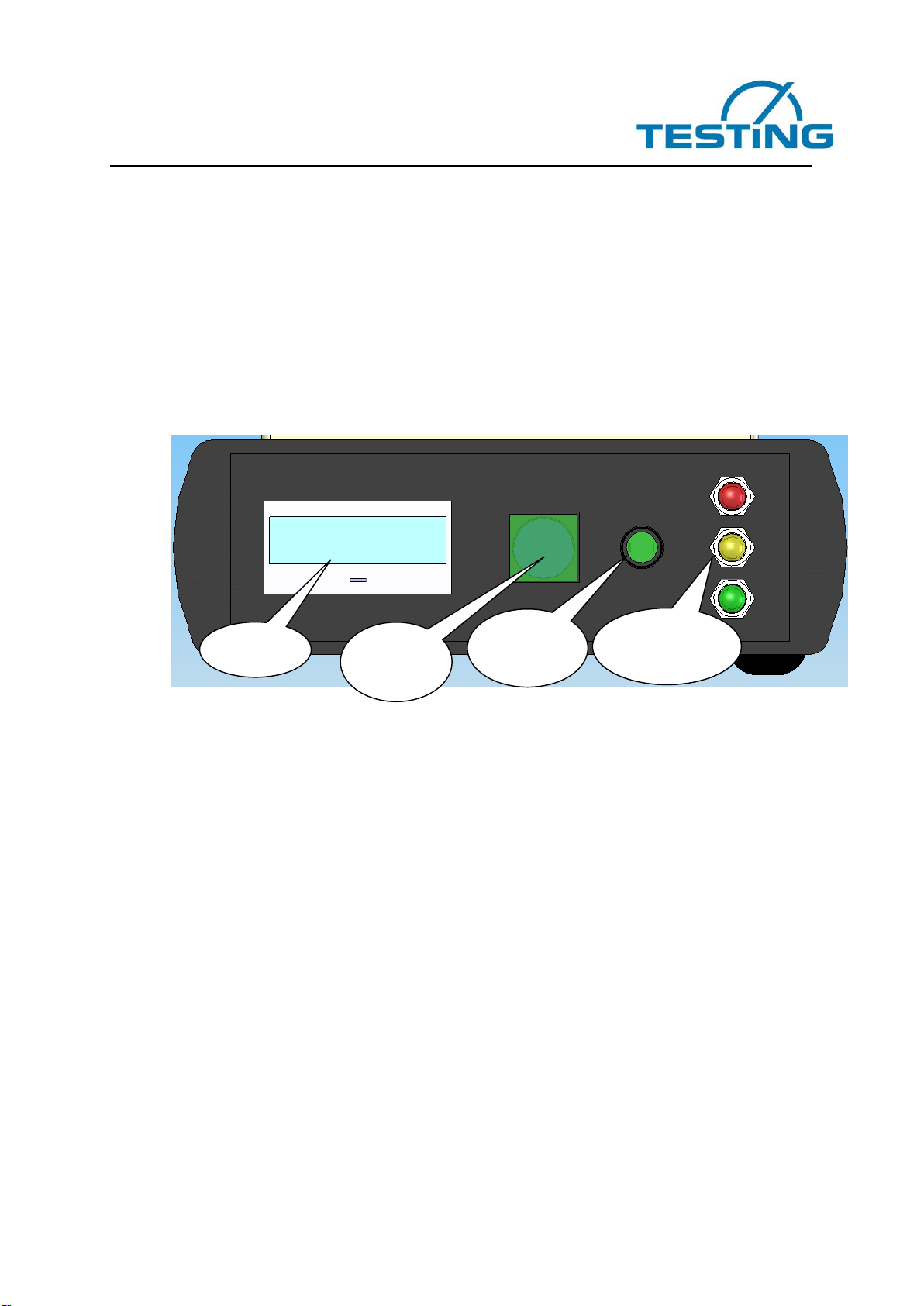

4 Switch the device on by using the power switch on the rear side. The green

READY lamp will now show.

5 Now briefly press the START button. (do not hold)

6 The system will now pull in the oil.

The lamps of the oil-level indicators will now show consecutively: green, amber,

and red.

The READY lamp will now go off.

The red lamp will now show, which means that the digital counter is set to zero.

The pump stops, and the solenoid valve closes.

The oil level now falls slowly.

As soon as the amber lamp goes off, the time measurement will begin.

When the green oil-level lamp goes off, the time measurement will stop.

The READY lamp will then go back on.

The clock will show the measured time, which is given in one-hundredths 1/100 of

a second.

Make a note of this time and of the room temperature, with a precision of 1°C for the

temperature.

Now repeat the above procedure, in accordance with Section 4.6.2 of the standard EN

196-6

Start

button

READ

Y lamp

Oil-level

indicators

clock

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

12

5. Checking and maintenance

In case of special maintenance work (e.g., repairs, exchange of parts, and all other work

that is not described in this Operating Manual), please get directly in touch with the man-

ufacturer.

The Blaine Apparatus requires practically no maintenance. After long service, we recom-

mend a thorough cleaning and refilling of the U-shaped tube with the required liquid.

If the apparatus has been used for a long time, or if the ambient conditions make an ex-

ternal cleaning of the apparatus necessary, please proceed as follows:

Switch off the main power switch on the reverse of the apparatus.

Disconnect the apparatus from the power supply.

Use a brush or vacuum cleaner to remove loose dust on the apparatus. If neces-

sary, the apparatus can then be cleaned with a moist cloth. Use anormal household

cleaning agent for this purpose.

Caution

Do NOT try to clean the apparatus with pressurized water, water or

other liquid spray, spray water that results in puddles, dripping

sponges, or any other unsuitable cleaning methods. If any of these

methods are used, the water or other liquid that results can enter the

control system and lead to permanent damages to the mechanical,

electrical, and/or electronic components of the apparatus.

All maintenance work involving components of the apparatus and/or the electrical system

must be conducted by qualified specialists.

At regular intervals, the liquid level must be checked. The fluid level must be equal to the

mark.

The glass cone should be lightly greased.

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

13

6. Troubleshooting

This section describes a number of simple problems tht can be easily solved during work.

Caution

All maintenance, inspection, testing, and repair work on apparatus

components or on the electrical system may be performed ONLY

by sufficiently qualified personnel.

PROBLEM

CAUSE

SOLUTION

The system will

not start.

There is no power to the system.

The pump or the electrical system

is defective.

The U-shaped tube is covered

with condensation or dirt.

Operate the main power switch

correctly, check the power ca-

ble, fuse on the main switch

and exchange it if necessary.

Get in touch with the Supplier.

Clean the U-shaped tube.

The manometer

fluid is not pulled

in correctly.

pump, valve is defective

The pneumatic lines are loose or

have leaks.

The U-shaped tube is covered

with condensation or dirt.

Get in touch with the Supplier.

Clean the U-shaped tube.

The measured val-

ues are not cor-

rect.

The constant for the apparatus is

not correct.

The calibration substance does

not properly match the cement

type.

The time metering is not correct.

The photoelectric barrier does not

function.

The measuring cell has not been

properly attached, or it has not

been turned correctly. There is a

leak in the connection between

the fittings.

Correctly determine the con-

stant for the system.

Choose the proper calibration

substance to correctly match

the cement type.

Regulate the photoelectric bar-

riers on the potentiometer.

Check the time metering. Clean

the U-shaped tube.

Check the glass cone

Note

If the device is to be sent for repair, the manometer liquid must be

sucked off in order to avoid further damages to the device.

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

14

In case of any malfunction, be sure to disconnect the Electronic Blaine Air-Permeability

Apparatus from the electric power supply.

Trouble

Solution to the problem

The READY lamp does not burn after the

Electronic Blaine Air-Permeability Appa-

ratus is switched on.

Check the fuse on the mains switch.

The apparatus pulls in the filling oil too fast,

or too slow.

Open the rear cover of the manometer col-

umn and adjust the throttle valve (please

see the diagram below).

7. Shutting down the system for lengthy periods

If the Blaine Apparatus is scheduled to remain out of operation for a lengthy period of

time, please follow these steps:

Disconnect the apparatus from the power supply.

Perform all required maintenance work.

Remove the liquid from the U-shaped tube.

Then cover the apparatus to protect it from dust

8. Scrapping

If the apparatus will not be used again, we recommend the following steps for scrapping:

Disconnect the power cable from the power supply.

Cover all sharp, protruding, or otherwise dangerous parts.

Disassemble the apparatus and scrap it in accordance with currently valid regula-

tions.

Potentiometer

to set the suck

velocity

Electronic

Blaine Air-Permeability Apparatus

1.0290/1.0290E

15

9. Spare parts and services

A great deal of care has been taken to ensure that this Operating Manual is correct. We

cannot, however, guarantee that it is without mistakes or errors, or that all information

contained herein will continue to remain valid in the event of technical changes.

9.1 Date of issue of this Operating Manual:

Version no. 11

Oct. 2016

9.2 Copyright

The copyright to this Operating Manual is held by the following company:

TESTING Bluhm & Feuerherdt GmbH

This Operating Manual is provided only for the using company, and the staff of this com-

pany. The information in this Operating Manual may not be:

Reproduced, or

Distributed, or

Provided to any other persons.

Any person acting in violation of the above stipulations may be prosecuted before a court

of law.

9.3 Address for technical support and spare-parts ordering

If you have any technical questions, or if you require spare parts, please get directly in

touch with the following address:

TESTING Bluhm & Feuerherdt GmbH

Motzener Str. 26b

DE –12277 Berlin

Germany

Tel.: +49 30 (0) 7109645-0

Fax: +49 30 (0) 7109645-98

www.testing.de

This manual suits for next models

1

Table of contents

Other TESTING Test Equipment manuals