Disclaimer: No representations or warranties are made with respect to the contents of this Installation Guide. GP:50 reserves the right to revise this guide

and to make changes periodically to the content hereof, without obligation to notify any persons of such revisions.

1. INTRODUCTION

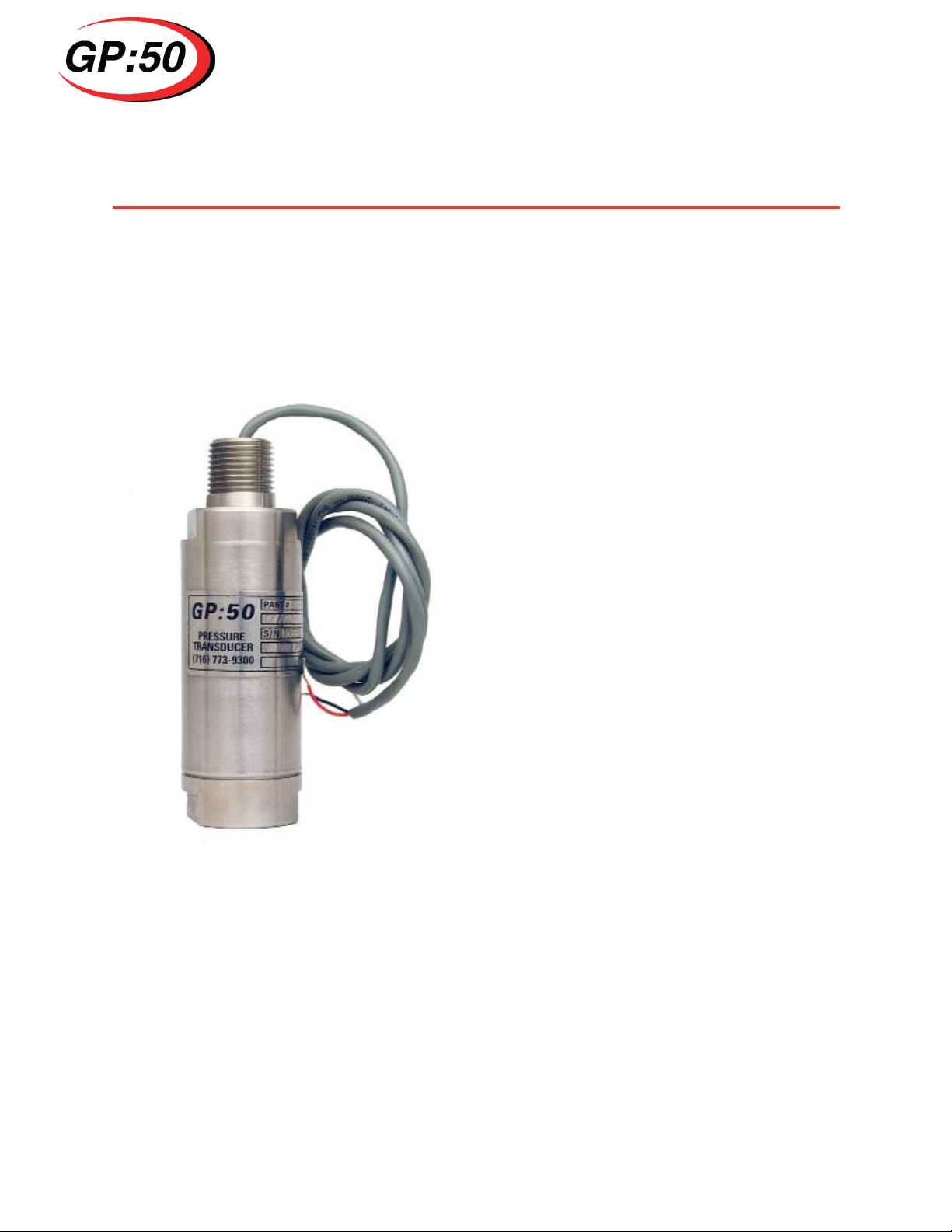

1.1 Product Description

The Model 311 is an oil field service pressure transmitter with a ¼”NPT(F) pressure port fitting (standard -

optional ports available), 4-20 mA output and measures pressures up to 75,000 psi (5168 bar).

1.2 Warning

Pressurized vessels and associated equipment are potentially dangerous. The product described

in the guide should be operated only by personnel trained in the procedures that will assure safety to

themselves, to others, to the equipment, and to the product. Specific warnings are noted as

in specific installation/operation sections.

1.3 Unpacking and Inspection

The Model 311 was carefully tested, inspected and packed. Upon receipt of the shipment thoroughly

inspect the transducer. If you see any visible signs of obvious shipping damage, notify the freight

company immediately.

1.4 Using this manual

This manual is intended to help the end user install, maintain, and provide general service of the GP:50

Model 311 pressure transmitter. The user should have a general understanding of current loops & gen-

eral instrument control. The Model 311 is a precision instrument and should be given the same care as

any other precision instrument during installation and operation.

INSTALLATION

1.5 Mounting/Process Connection

The standard Model 311 transducer is supplied with a ¼” NPT(F) pressure port. Installation of the device

shall be in accordance with industry standard pipe fitting requirements for this size .Torque shall only be

applied to the transducer during installation (or removal) from the wrench flats provided on the pressure

port. As a general rule of thumb, the device shall be torqued “wrench-tight” to preclude leakage from the

process connection. Contact GP:50 sales personnel for additional information if required, or for specific

installation requirements for non-standard process connections.

Insure media is compatible with 15-5 SST (standard material, optional materials available, check part

number (Appendix A) to verify wetted material) to avoid premature corrosion of the diaphragm. This can

cause performance degradation and eventual sensor rupture/failure.

Properly tighten process connections before applying pressure to insure no leaks or mechanical failure

can occur.

Never insert sharp objects into diaphragm. This could cause permanent damage the sensor and / or

mechanical failure/diaphragm rupture.

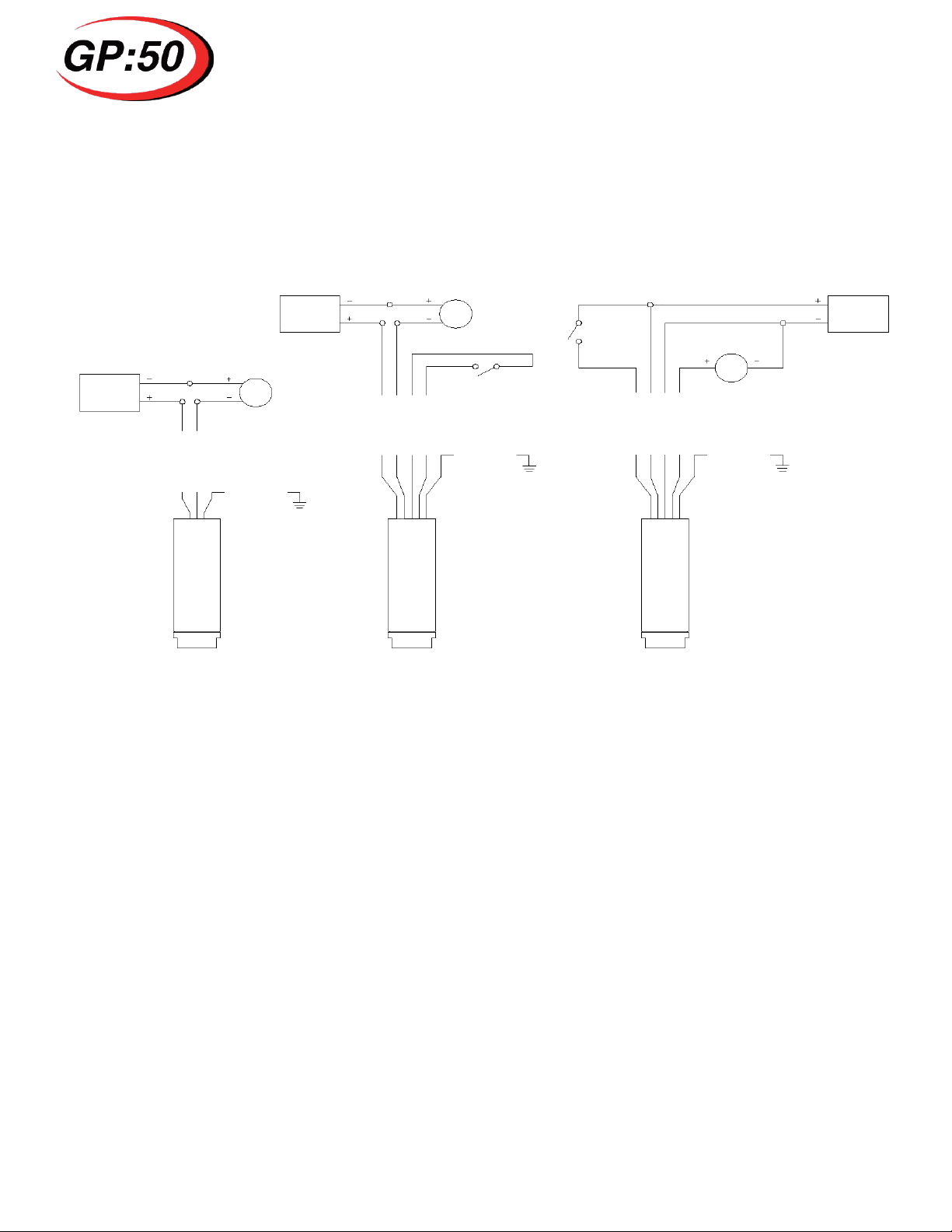

1.6 Power Supply Connection

For best operation the pressure transmitter needs clean, regulated power with an output impedanance

less than 20 ohms. Minimum voltage is 10 volts with no resistive loading, to a maximum of 36 Vdc

(Z, P + X Series) (28 Vdc for I, AI + GI Series units). As loads are added to the current loop (galvanic bar

riers, current measuring devices resistors), the minimum excitation voltage must increase in order to

maintain proper operating voltage.

Exceeding maximum supply voltage can damage electronics and cause malfunctions or failure. With In-

trinsically Safe units, this can cause an explosion. Please refer to the attached IS connection diagram

(Appendix B), and applicable local codes, for proper electrical installation.

Always inspect/clean electrical connection and sealing surface prior to installation.

Δ

!

Δ

!

Δ

!

Δ

!

Δ

!