Copyright HK Instruments 2021 www.hkinstruments. Installaonversion2.02021

Thesellerisobligatedtoprovideawarrantyofveyearsforthedeliv-

eredgoodsregardingmaterialandmanufacturing.Thewarrantyperiod

isconsidered tostart on thedelivery date ofthe product.If adefect

in raw materials or a produconawis found, theseller is obligated,

whentheproductissenttothesellerwithoutdelayorbeforeexpira-

onofthewarranty,toamendthemistakeathis/herdiscreoneither

by repairing the defecve product or by delivering free of charge to

thebuyeranewawlessproductandsendingittothebuyer.Delivery

costsfor the repairunderwarrantywillbe paidbythebuyerandthe

return costs by the seller. The warranty does not comprise damages

causedbyaccident,lightning,oodorothernaturalphenomenon,nor-

malwearandtear,improperorcarelesshandling,abnormaluse,over-

loading,improperstorage,incorrectcareorreconstrucon,orchanges

andinstallaonworknotdonebytheseller.Theseleconofmaterials

fordevicespronetocorrosionisthebuyer’sresponsibility,unlessother-

wiseislegallyagreedupon.Shouldthemanufactureralterthestructure

ofthedevice, thesellerisnot obligatedtomakecomparable changes

todevicesalreadypurchased.Appealingforwarrantyrequiresthatthe

buyerhascorrectlyfullledhis/herduesarisenfromthedeliveryand

stated in the contract. The seller will give a new warranty for goods

thathavebeenreplacedorrepairedwithinthewarranty,howeveronly

totheexpiraonoftheoriginalproduct’swarrantyme.Thewarranty

includestherepairofadefecvepartordevice,orifneeded,anewpart

ordevice,butnotinstallaonorexchangecosts.Undernocircumstance

isthesellerliablefordamagescompensaonforindirectdamage.

STEP 8: ZEROING THE DEVICE

WARRANTY POLICY

RECYCLING/DISPOSAL

The parts le over from installaon should be

recycled according to your local instrucons.

Decommissioned devices should be taken to a

recyclingsitethatspecializesinelectronicwaste.

Span point calibration

1)Autozerocalibraon

Autozerocalibraon (-AZ) is an autozero funcon in the form ofan

automaczeroingcircuitbuiltintothePCBboard.Theautozerocali-

braon electronically adjusts the transmier zero at predetermined

me intervals(every10minutes).Thefunconeliminatesalloutput

signaldriduetothermal,electronicormechanicaleffects,aswellas

theneedfortechnicianstoremovehighandlowpressuretubeswhen

performing inial or periodic transmier zero point calibraon. The

autozeroadjustmenttakes4secondsaerwhichthedevicereturnsto

itsnormalmeasuringmode.Duringthe4secondadjustmentperiod,

theoutputanddisplayvalueswillfreezetothelatestmeasuredvalue.

Transmiersequippedwiththeautozerocalibraonarevirtuallymain-

tenancefreeandmanualzeroingisnotrequired.

NOTE! Always zero the device before use.

Tozerothedevicetwooponsareavailable:

1)Autozerocalibraon(manualzeroingnotrequired)

2)ManualPushbuonzeropointcalibraon

2)ManualPushbuonzeropointcalibraon

NOTE:Supplyvoltagemustbeconnectedatleastonehourpriortozero

pointadjustment.

a)Disconnectbothpressuretubesfromthepressureportslabeled+

and–.

b)PushdownthezerobuonunltheLEDlight(red)turnsonandthe

displayreads“zeroing”(displayopononly).(seeFigure4)

c)Thezeroingofthedevicewillproceedautomacallyin4seconds.

Zeroingledlightsonlyforamoment.Zeroiningiscompletewhen

thedisplayreads0(displayopononly).

d)ReinstallthepressuretubesensuringthattheHighpressuretube

isconnectedtotheportlabeled+,andtheLowpressuretubeis

connectedtotheportlabeled−.

b)Pushdownthezerobuon(joysck)unltheLEDlight(red)

turnsonandthedisplayreads“zeroing”(displayopononly).(see

Figure6)

c)Thezeroingofthedevicewillproceedautomacally.Zeroingis

completewhentheLEDturnsoff,andthedisplayreads0(display

opononly).

d)Reinstallthepressuretubes,ensuringtheHighpressuretubeis

connectedtotheportlabeled+,andtheLowpressuretubeis

connectedtotheportlabeled−.

Pressdownbuon

LEDturnsON

Displayreads“Zeroing”

LED

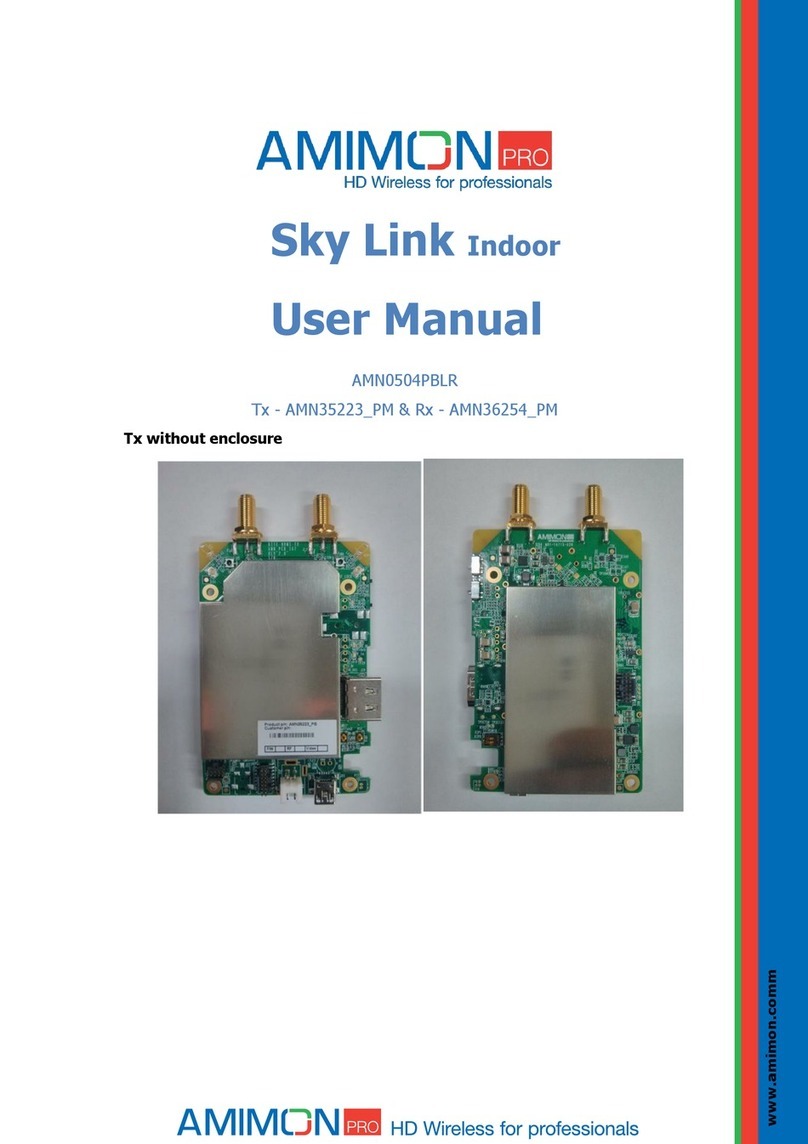

Figure 4

Oponalspanpointcalibraon(-S)isusedforadjusngtheupperrange

value of the measurement range. The span point calibraon has been

performedbythemanufactureranditisusuallynotnecessarytoadjust

thespansengonsite.Insomecases,spanpointeldcalibraonmay

benecessary,e.g.incaseofannualcalibraonincleanroomapplicaons.

Thespanpointcalibraonrequiresaceredhighaccuracypressurecali-

bratorforreferencepressure.

Toperformaspanpointcalibraon:

1) Connect pressure tubes between the transmier and the pressure

calibratorconnectors.Connectposivepressuretoport“+”andnega-

vepressuretoport“-”.

2)Setthecalibratorsupplypressuretomatchtheupperrangevalueof

themeasurementrangeusedinthetransmier(e.g.whenused-50…

+50Pameasurementrange,setthecalibratorpressureto+50Pa).

3)Openthelidofthetransmier.

4)Performamanualpushbuonzeropointcalibraon(seestep8).

5)Adjusttheupperrangevaluebyturningthetrimmer(seeschemacs)

witha screwdriverunlthe value shownonthe transmier display

correspondstothesetupvalueofthecalibrator.