5

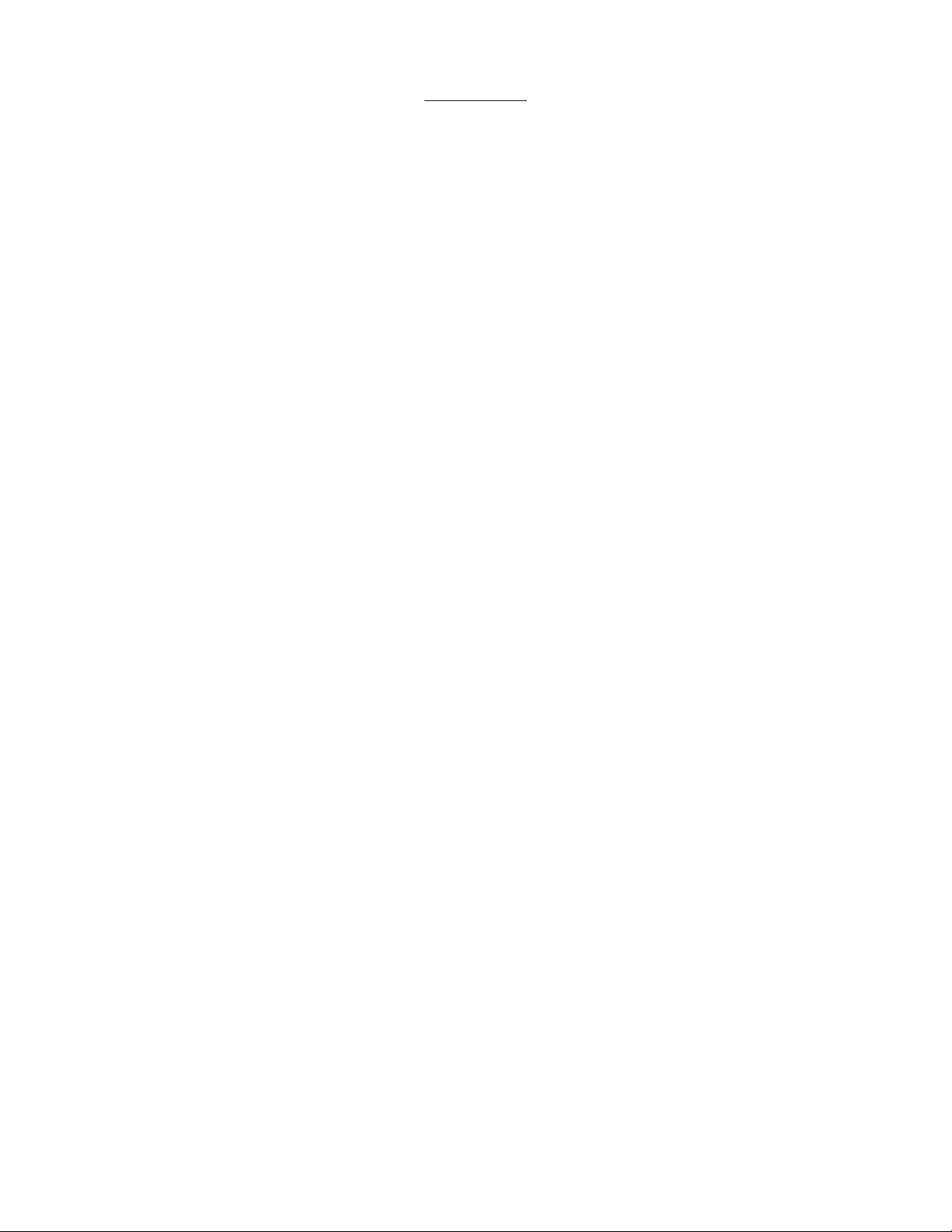

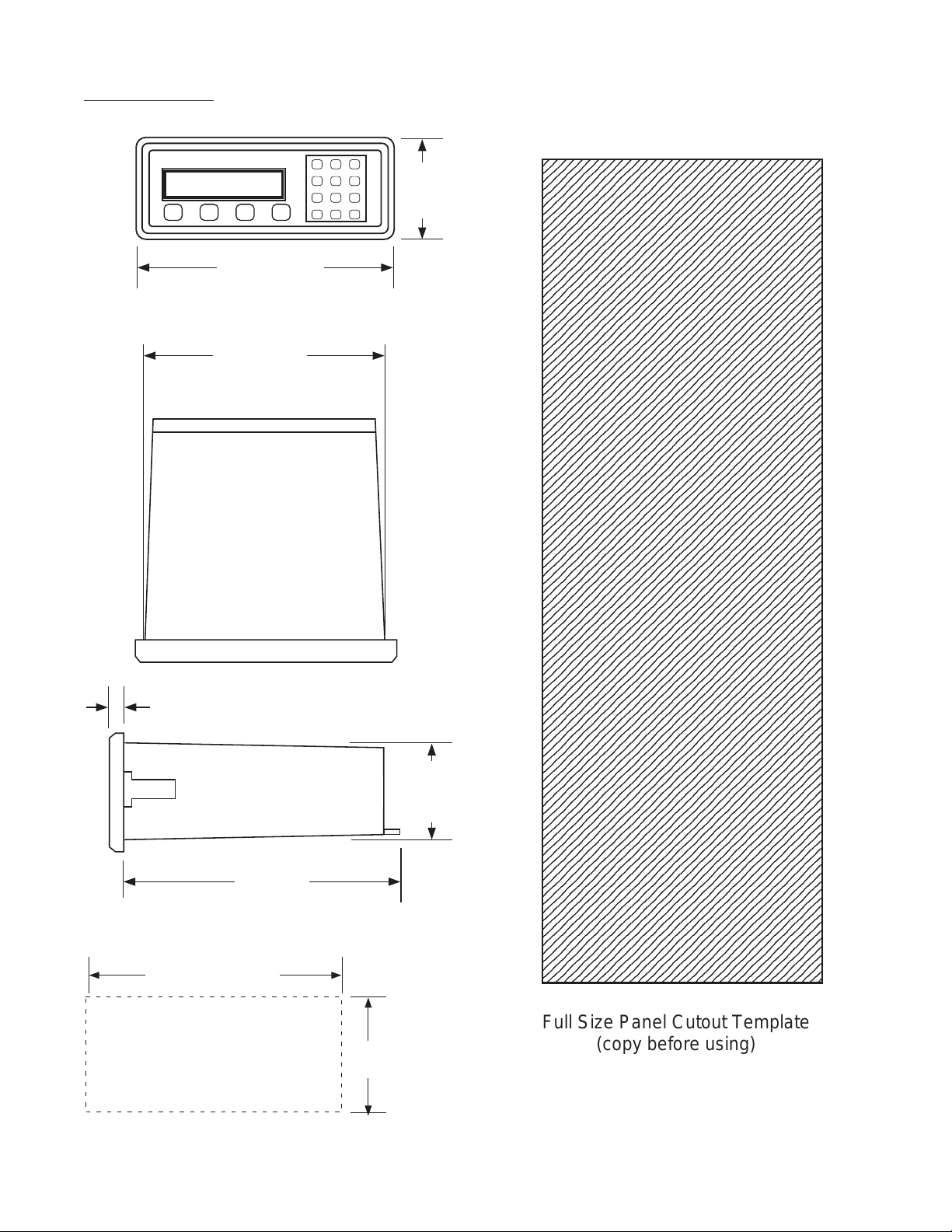

1-6 Dimensions

PANEL

CUTOUT 2.50 -0, +0.02

(63.5 -0, +0.5)

7.375 -0, +0.04

(187.3 -0, +1)

7.375

(187.3)

(NOM.)

0.53

(13.5)

6.0

(152.4)

2.48

(63)

(NOM.)

(NOM.)

ABCD

1 2 3

4 5 6

7 8 9

CLR

0

SET

8.17

(207.5)

3.31

(84)

12345678901234567890123456789012123

1

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

3

12345678901234567890123456789012123

Full Size Panel Cutout Template

(copy before using)