Sorotec PRO ITG 3 axes Benezan User manual

SOROTEC GmbH

Withig 12

77836 Rheinmünster

Tel.: +49 (0) 7227-994255-0

Fax: +49 (0) 7227-994255-9

E-Mail: [email protected]

Web: www.sorotec.de

Assembly Instructions

Control kit

PRO ITG 3 axes Benezan

Version 1.0.0

ETS.S3JMCBP.OB.02.PB

Seite 2 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Introduction

We thank you for the trust you have shown in us by

purchasing the control kit. We recommend reading

these instructions through completely before assem-

bly and then assembling the kit step by step as de-

scribed.

Required tools

Ordinary hand tools such as screwdrivers of various

shapes and sizes, wire cutters, etc. should be availa-

ble. The following tools are also required:

• Electronics soldering equipment

• Wire stripper

• Crimping pliers for wire end ferrules

• Crimping pliers for cable lugs

• Thread cutter for M4 and M5

Attention Danger!

Before opening the housing, the mains plug must be

pulled out!

Attention!

Only carry out the work if you are familiar with the

necessary actions familiar and appropriate

Tools are in place.

Sorotec GmbH assumes no liability for damage to

property or personal injury that occurs during assem-

bly or operation of the CNC control!

Attention Danger!

It is expressly pointed out that the electrical connec-

tion is the responsibility of the electrician! In parti-

cular, the correct connection of the protective con-

ductor and the subsequent protective conductor test

must be carried out by electrotechnically qualied

personnel in accordance with the relevant national

regulations!

Seite 3 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Scope of delivery

Illustration Designation Num-

ber

Sheet steel housing

PRO2 1

Connection panel 1

Elastic adhesive feet 4

Sticker set 1

Wiring duct 3

Switching power supply

48 V 1

Coupling relay 1

Interface Advance PRO 1

Sub-D cable 1:1 1

LED board with cable 1

1

2

3

4

5

6

7

8

9

10

Illustration Designation Num-

ber

Relay board 1

IEC connector with line

lter, fuse holder and 2

fuses 10 A slow

1

Fuse holder 3

Microfuse

6.3 A slow 2

Microfuse 5 A slow 1

Power switch 1

Power cord 1

Built-in socket 2

Fan 80 x 80 x 25 mm

24 V 1

Fan damper 1

11

12

13

14

15

16

17

18

19

20

Seite 4 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Illustration Designation Num-

ber

Dust lter 1

Built-in socket Binder

2-pole 3

Built-in socket Binder

3-pole 3

Built-in socket Binder

6-pole 2

Cable connector binder

2-pole 3

Cable connector binder

3-pole 3

Cable connector binder

6-pole 2

Sub-D socket

9 pin 5

Sub-D connector

9 pin 5

Sub-D mounting kit 6

Sub-D housing for

9 pin 5

21

22

23

24

25

26

27

29

30

31

Illustration Designation Num-

ber

Sub-D socket

25-pin 1

Sub-D connector

25-pin 1

Round connector 3

Round socket 4

Flat receptacle 7

Ring cable lug 8

End sleeves

range 1

Shrink tubing

range 1

Emergency stop switch 1

Control line

2 x 0,5 mm² 3 m

Patch cord RJ45 0,5 m 3

33

34

35

36

37

38

39

40

K1

K2

Seite 5 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Illustration Designation Num-

ber

Ribbon cable

25 pole 0.4 m

PVC core cable

0.25 mm² violet 2 m

PVC core cable

0.50 mm² dark blue 20 m

PVC core cable

0.50 mm² black 10 m

PVC core cable

0.50 mm² violet 2 m

PVC core cable

0.50 mm² orange 2 m

PVC core cable

0.50 mm² light blue 2 m

PVC core cable

0.50 mm² red 2 m

PVC-Aderleitung

0.75 mm² black 10 m

PVC core cable

1 mm² black 10 m

PVC core cable

1 mm² light blue 10 m

PVC core cable

1 mm² green/yellow 10 m

K3

L1

L2

L5

L6

L7

L8

L9

L10

L11

Illustration Designation Num-

ber

Mounting rail 0.16 m

Pan head screw

DIN 7981

M3,5 x 9,5

18

Cylinderhead screw

DIN 84

M3 x 6

M5 x 6

16

3

Cylinderhead screw

DIN 6912 M6 x 20 2

Countersunk screw

DIN 965

M3 x 12

M4 x 16

M4 x 40

2

8

4

Allen at head screw

DIN 7381

M3 x 6

M4 x 6

6

4

Washer DIN 125 M6 3

Tooth lock washer DIN

6797 M6 10

Hexagon nut DIN 934

M3

M4

M5

M6

2

12

3

5

Spacer sleeve

M3 hexagon 10 mm

2 x M3 internal thread

8

TS

S1

S3

S2

S4

S7

S5

S6

S8

S9

U1

UZ

M4

M6

M5

M3

D1

Seite 6 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Preparation of the housing

For this construction phase you will need: #

1 Sheet steel housing 1

4 Adhesive feet 3

1 Mounting rail TS

3 Cylinderhead screw M5 x 6 S3

1 Power switch 16

1 Fan 19

1 Fan damper 20

1Dust lter for fans 21

4 Countersunk screw M4 x 40 S7

4 Nut M4 M4

3 Fuse holder 13

2Microfuse 6.3 A 14

1Microfuse 5 A 15

1 IEC built-in connector 12

2 Countersunk screw M3 x 12 S5

2 Nut M3 M3

1 LED board with cable 10

2 Flat headed screw M3 x 6 S8

3 Wiring duct 5

2 Built-in socket 18

8 Countersunk screw M4 x 16 S6

Prepare the housing 1for the installation and the

wiring of the modules as follows:

• Open (if not already done) the pre-cut

installation openings for the power switch 16 ,

the IEC built-in plug 12 and the three fuse

holders 13 .

• Cut the threads for the mounting screws:

8 x M4 for the sockets

3 x M5 for the mounting rail (see Figure 12)

• Remove all burrs and sharp edges from the

installation openings.

• Stick the rubber feet 3into the four corners

on the bottom of the case. Lateral distance

approx. 8 mm each.

• Mount the DIN rail TS cut to 16 cm with the

screws S3 in its place in the front part of the

housing (see Figure 12).

• Slide the power switch 16 with the „0“

upwards into the rectangular opening on the front

of the housing until the edge of the switch is

ush. The switch is self-locking, screwing is not

necessary.

• Mount the fan 19 and the fan damper 20 with

screws S7 and nuts M4 with the connection

cable pointing downwards behind the grille

opening on the front. Place the damper on the

inside between the fan and the housing and the

grille cover on the outside. Pay attention to the

direction of ow: The cool air should be blown

into the housing!

• Slide the cover frame 21 with the inserted

dust lter onto the grille cover of the fan.

• Mount the IEC built-in connector 12 with

screws S5 and nuts M3 in the opening provided

on the rear.

• Mount the LED board 10 in its place in the

front of the device with screws S8 .

• Lay the self-adhesive wiring duct 5. Use the

course shown in Figure 12 as a guide.

• Mount the two built-in sockets 18 with screws

S6 .

• Now build the three fuse holders 13 into the

holes below the sockets and next to the built-in

plug.

• Equip the fuse holders next to the sockets (F1

and F2) with a 6.3 A ne fuse 14 each.

• Equip the fuse holder next to the built-in

connector (F3) with the 5 A microfuse 14 .

Seite 7 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Grounding screws

For this construction phase you will need: #

2 Cylinderhead screw M6 x 20 S4

3 Washer M6 U1

10 Tooth lock washer M6 UZ

5 Nut M6 M6

Danger!

Poor grounding is a common and dicult source of

errors. Carry out the work with special care.

The holes for the earthing points are located on the

bottom of the housing and on the rear wall (see also

Figure 12). The screws installed here must have

good conductive contact with the housing plate.

• Remove the paint from one to two

millimeters around the holes.

• Mount the grounding screws as shown in

pictures 1 to 3.

• The earthing screw of the housing cover is

connected to the earthing point on the oor

before the housing is closed.

Note

The connection of earthing cables to screws is

made with ring cable lugs between toothed lock

washers.

Fig. 1: Earthing screw on the oor (left) and on the rear wall

Fig. 2: Grounding screw rear wall outside

Fig. 3: Ground screw cover

Seite 8 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Power supply and coupling relay

For this construction phase you will need: #

1 Switching power supply 48 V 6

4 Flat headed screw M3 x 6 S8

1 Coupling relay 7

• Assemble the 48 V power supply 6with

screws S8 , as shown in Figure 22.

The coupling relay 7is used to optionally control

the milling spindle with a frequency converter. See

circuit diagram „Infeed / Supply“ for details.

• Place the coupling relay on the mounting rail

as shown in Figure 12.

Preparing the motors

Note

The settings described here refer, for example, to

the JMC drive motors preferably used by Soro-

tec. The conguration of motors from other ma-

nufacturers can dier in scope and procedure.

The conguration is based on the tables printed on

the motors (see gure). We recommend setting the

DIP switches of the output stages integrated in the

motors as follows:

Resolution

A stepper motor performs 200 steps of 1.8 ° per re-

volution. With the DIP switch setting shown, the out-

put stage divides these full steps into 16 micro steps

each. This then results in 3200 steps per revolution

of the motor. With a spindle pitch of 10 mm / revo-

lution, one microstep corresponds theoretically to a

travel distance of 0.003125 mm.

If another resolution is selected, it must be chan-

ged accordingly in the software setting.

Triggering and direction of rotation

The switch S5 determines whether a motor step is

triggered at the beginning or at the end of a switching

pulse. To avoid step losses, the position Pulse end /

S5 On has proven itself („falling edge“, „down edge“).

The switch S6 determines the basic direction of rota-

tion: O for CCW (counterclockwise) and On for CW

(clockwise).

Fig. 4: DIP switch on the output stage integrated in the motor

Fig. 5: Table with switch positions

Seite 9 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Fig. 6: Adapter board with connection cable

Fig. 7: Signal chain from PC, Eding V5A, adapter board and

PRO control

Fig. 8: Signal chain from PC, Eding V5A, adapter board and

PRO control

Fig. 9: Jumper-Setting Eding V5A

Interface Advanced Pro

and EdingCNC

When using EdingCNC as software, the following

points must be observed when operating this control:

• The adapter board shown in Figure 6 must be

inserted between the Eding V5A and the MIDI

control. Figure 7 shows the complete signal

chain.

In addition, it is possible to connect a tool

length sensor to terminal X1 of the adapter, as

described in Figure 8, which would otherwise

occupy the input for the reference switch of a

fourth axis on the Advanced Pro interface. The

middle terminal serves as an input for the pulse

signal (tachometer) of a spindle.

• The jumpers on the V5A board must be set as

shown in Figure 9.

• The jumpers of the Interface Advanced Pro

must be set as described on the next page in

Figure 11.

Seite 10 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Preparation of the interface

Depending on the software used, the Advanced In-

terface Pro must be adapted by moving jumpers.

Estlcam

For use with Estlcam, insert the Jumpers as follows:

• 1-2, 4-5, 6-7, 10-11 (see gure 10)

Fig. 10: Jumpering for use with Estlcam

EdingCNC

For use with EdingCNC set the jumpers as follows:

• 2-9, 4-5, 6-7, 10-11 (see gure 11)

Fig. 11: Jumper setting for use with EdingCNC

Seite 11 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Fig. 12: Gehäuse mit Einbauten vor Beginn der Verkabelung

Relay board and interface

For this construction phase you will need: #

1 Relay board 11

1Interface Advanced Pro 8

16 Flat headed screw M3 x 6 S2

8 Spacer sleeve D1

• Mount the relay board 11 und das Interface

8with 8 screws S2 ueach and four spacer

sleeves D1 , each, as shown in Figure 12.

Wiring

For this construction phase you will need: #

1 Connection panel 2

8 Pan head screw S1

2 6-pole built-in socket 24

3 3-pole built-in socket 23

3 2-pole built-in socket 22

5 D-Sub socket 9-pin with solder cup 28

5 D-Sub connector 9-pin with solder cup 29

5 D-Sub mounting kit 30

8 Ring cable lug 37

7 Flat receptacle 36

4 Round socket 35

3 Round connector 34

1 Shrink tubing 39

1 End sleeves 38

3 Patch cable RJ45 K2

PVC core cable according to circuit diagram

All the information required for wiring is contained in

the circuit documentation that you received with the-

se instructions. In addition to the connections to be

created, this particularly applies to:

• Cable cross-sections

• Wire colors

• Pinouts of connectors

Please take the time to study the circuit documenta-

tion in detail before you start wiring.

These instructions provide general information - on

how to solder sockets, for example.

In addition, pictures show the gradual completion

of the wiring as an example of sensible laying and

bundling of the lines.

Seite 12 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Line ends

Please always use the right equipment for the cable

ends for your connections:

• Wire end sleeves for screw terminals

• Flat receptacles for plug connections

• Ring cable lugs for earthing

Assembly of the installation sockets

Mount the connection panel 2with screws S1 in

front of the opening on the rear of the housing. For

wiring the built-in sockets 24 and 26 it has proven

useful to rst roughly cut the patch cables K2 to

length, solder them outside the housing and only

then install the sockets. Also note the following note

on soldered connections.

Solder connections

Cross-shorts are a frequent source of errors in sol-

dered connections on plugs and sockets. It is there-

fore essential to isolate each individual pin with heat

shrink tubing (see Figure 15).

Twisted cables

To reduce electrical elds, the cables for powering

the motors must be twisted in pairs. See also Figure

15.

Fig. 13: Sockets for cooling and milling spindle, fuse protec-

tion, built-in plug with line lter

Fig. 14: Terminal strips on the power supply

Fig. 15: Each pin individually isolated with shrink tubing, pow-

er cables twisted

Seite 13 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Fig. 16: Jumper with round plugs / sleeves for optional fre-

quency converter connection

Fig. 17: Ground connection of cover and housing

Fig. 18: Basic cabling with mains voltage supply via switches and fuses

Fig. 19: Sockets connected via fuses

Seite 14 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Fig. 20: Jumper for frequency converter connection and emergency stop wiring

Fig. 21: Power supply cabling and axis connections

Fig. 22: Ribbon cable with D-Sub socket on the rear wall of the housing

Seite 15 / 15

Instructions for control

PRO ITG 3 axes Benezan

www.sorotec.de V 1.0.0

Further wiring

For this construction phase you will need: #

1 Ribbon cable 25pole K3

1 D-sub socket 25pole 32

1 D-sub connector 25pole 33

1 D-Sub mounting kit 30

1 6-pole cable connector 27

1 Emergency stop switch 40

Control line 2 x 0.5 mm K1

Ribbon cable

To produce the connection cable from the interface to

the rear wall of the housing, the ribbon cable K3

must be provided with a plug 33 and socket 32 .

Make sure that the cable is inserted correctly.

Slipping or twisting leads to unwanted cross-cir-

cuits.

Normally, a special tool is used for the pressing pro-

cess, which is not worth buying for hobby craftsmen.

However, correct pressing is also possible between

the protective jaws of a vice or with a screw clamp on

the edge of a table top.

Fig. 23: Ribbon cable with plug, axis assignment of the four

outputs

X

Y

Z

4

In any case, test your result with a continuity

tester for contact from one end to the other and

then for short circuits: each pin to ground, then

each pin to each other. Contact failures and short

circuits are a common and hard-to-nd cause of

malfunction.

Emergency stop switch

• Mount the emergency stop switch 40 so that it

is easily accessible near the machine.

• Wire the switch to the control line K1 .

• Solder the cable connector 27 to the free end

of the control line and mount the connector

housing.

• Connect the emergency stop to the control.

If an emergency stop switch is already available

(such as on all machines in the Hobby Line), you

should preferably connect it. The switch enclosed

with this kit can either be left out or integrated in a

series connection.

Table of contents

Other Sorotec Control System manuals

Popular Control System manuals by other brands

Woodway

Woodway Micro-Link ZE0187 installation guide

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SC-SL4-AE2 Technical manual

LOGICDATA

LOGICDATA LogicS Mounting instructions

Mi-Light

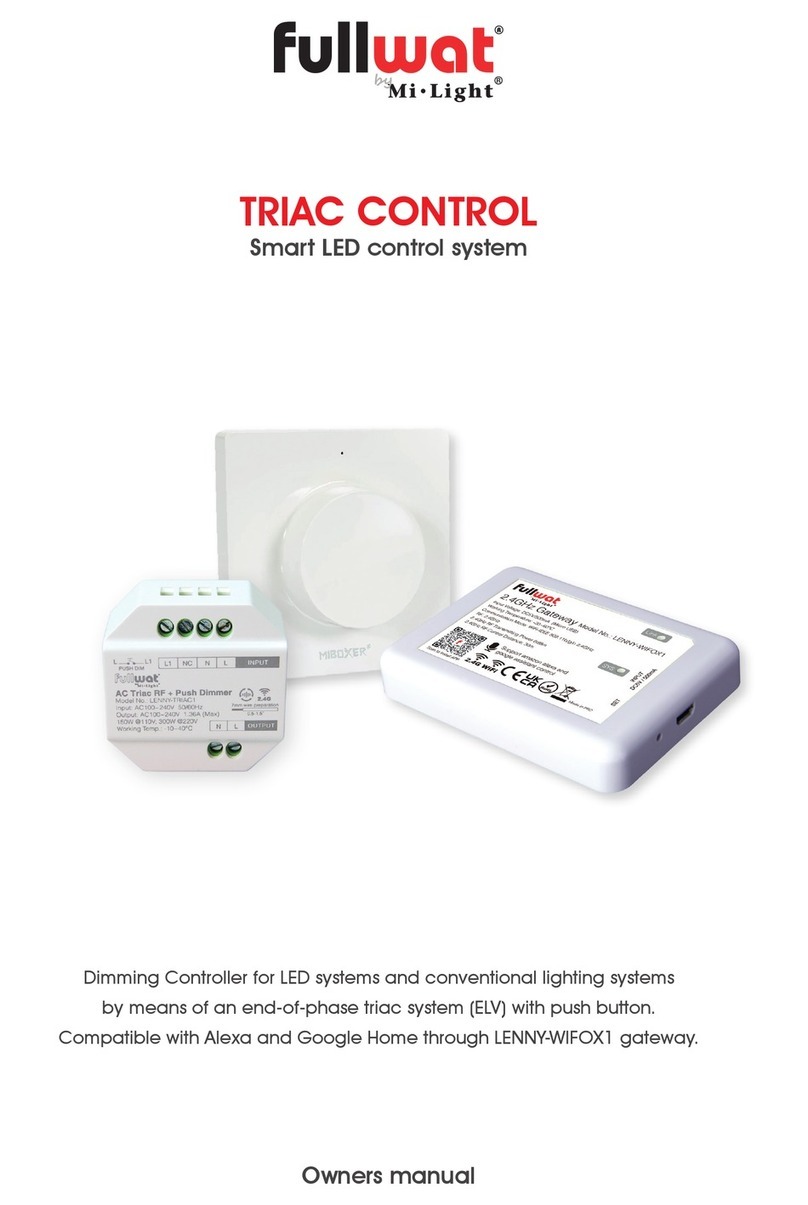

Mi-Light fullwat TRIAC CONTROL owner's manual

Next Wave Automation

Next Wave Automation Digital Duplicator manual

Waterway

Waterway NEO 1100 instruction manual

btsr

btsr WINDINGFEEDER operating manual

Thermo King

Thermo King SR-2 SmartReefer2 Diagnostic manual

NPI

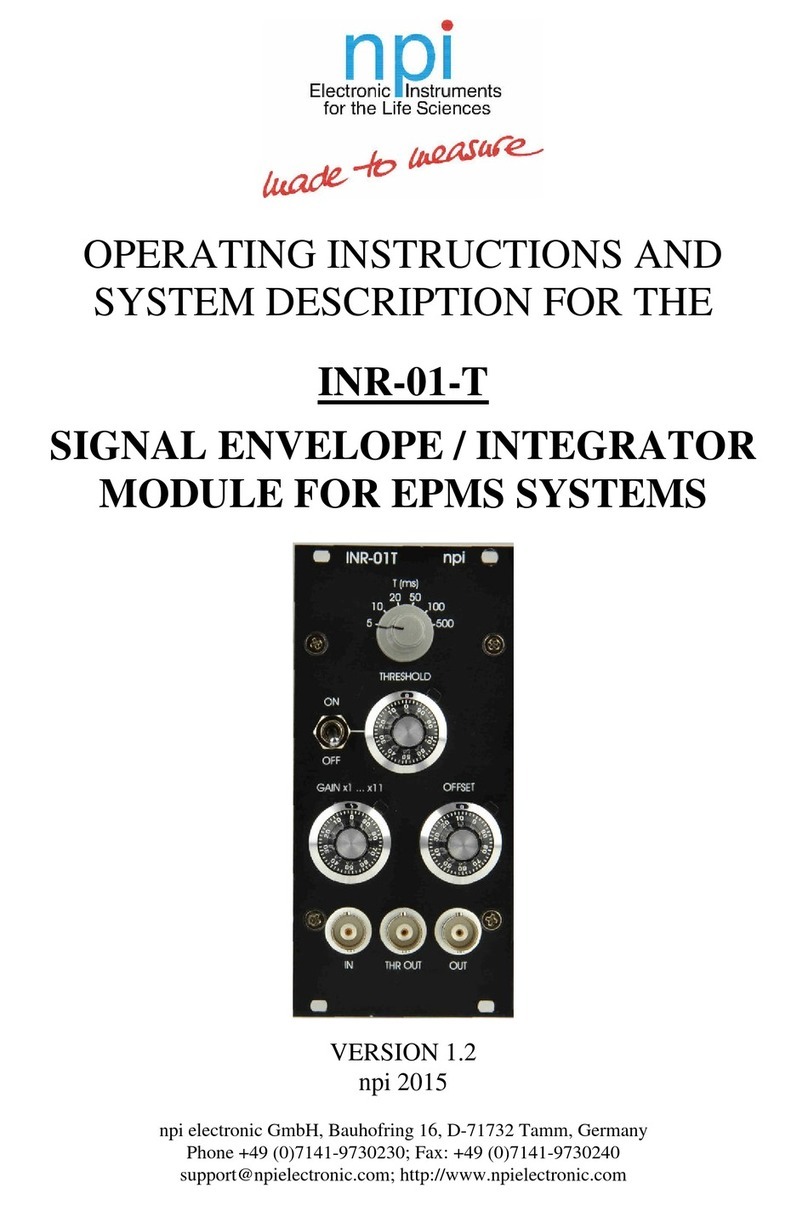

NPI INR-01-T Operating instructions and system description

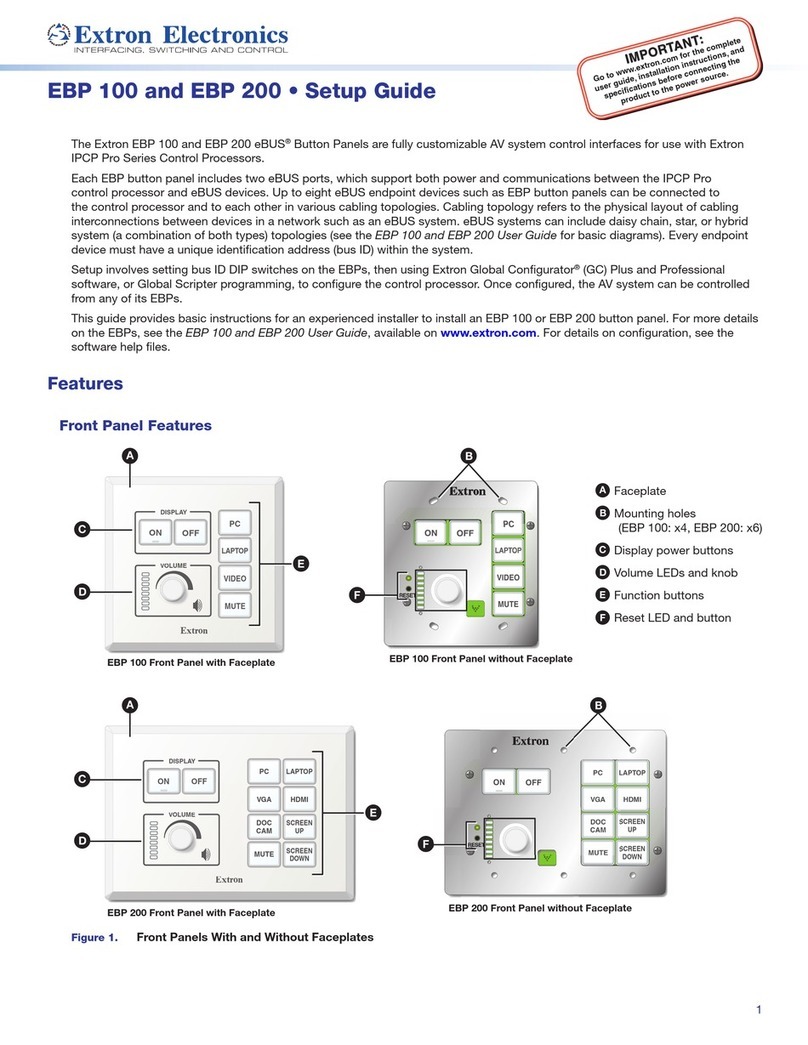

Extron electronics

Extron electronics EBP 100 Setup guide

Crestron

Crestron 4K DigitalMedia 3-Series quick start guide

Parklio

Parklio Barrier user manual