Contents Contents

Contents

ControlComponents.............................................2

ComponentManuals.............................................3

Warnings.............................................................4

IntelligentPaintKitchenOverview..........................7

InstallationandWiring.........................................25

SoftwareSetup...................................................44

TouchscreenSoftware........................................57

NetworkSetupandConguration........................92

SetUptheEmailServer...............................94

CreateaPassword......................................95

Operation...........................................................97

EventsandLogs...............................................121

Troubleshooting................................................131

SystemSoftwareTasks....................................133

Repair..............................................................137

Parts................................................................140

KitsandAccessories.........................................143

Dimensions......................................................144

TechnicalSpecicationsfortheTouchscreen

Box,SupervisorBox,andExpansion

Box....................................................146

AppendixA:SystemDesign..............................147

AppendixB:Cables..........................................150

AppendixC:ElectricalSchematics.....................151

AppendixD:Communication

Conguration......................................154

AllenBradleyPowerFlex.............................154

Mitusbishi..................................................157

AppendixE:NodeIDAssignments....................158

AppendixF:AgitatorPartNumbers....................159

AppendixG:UpdatetheIntelligentPaintKitchen

Software.............................................160

AppendixH:Master/ClientSetup.......................161

CongureMultipleDisplays........................162

AtPowerUp..............................................163

DuringNormalOperation............................163

Control Control

ControlComponents Components

Components

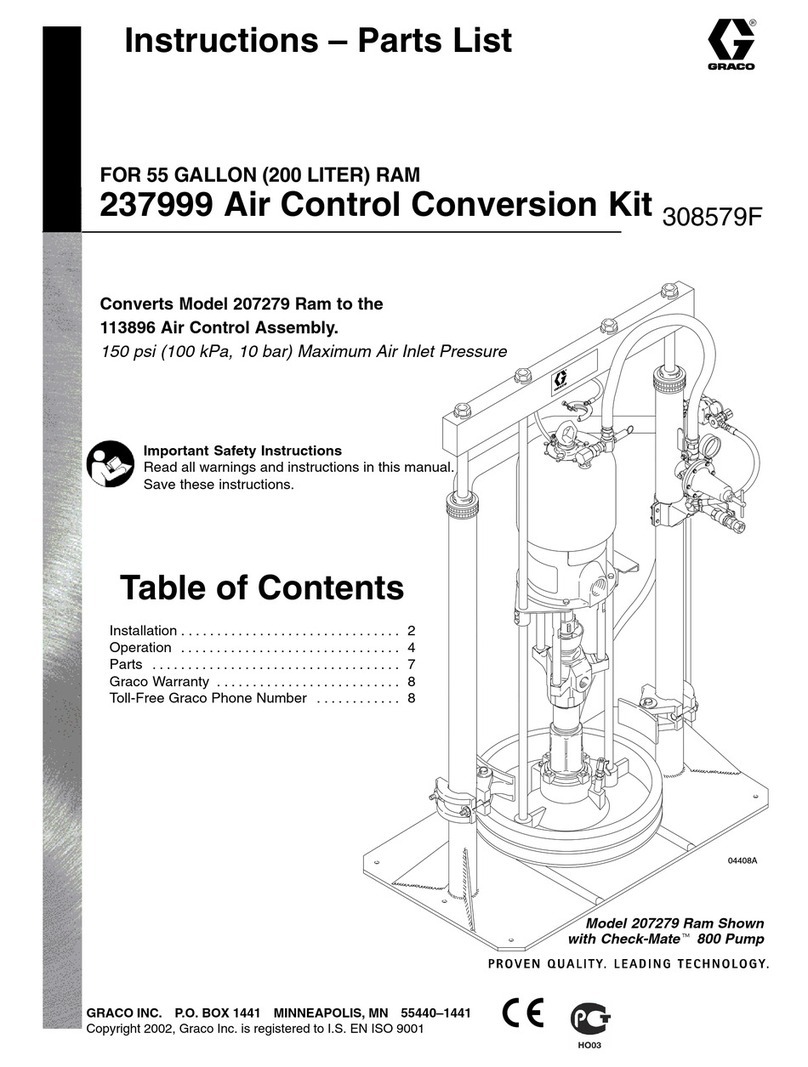

Thefollowingcomponentsaredescribedinthismanual.Forallothercomponents,seethespeciccomponent

manual.

Part Part

Part

No. No.

No.Description Description

DescriptionUsage Usage

UsageOperating Operating

Operating

Voltage Voltage

VoltageApprovals Approvals

Approvals

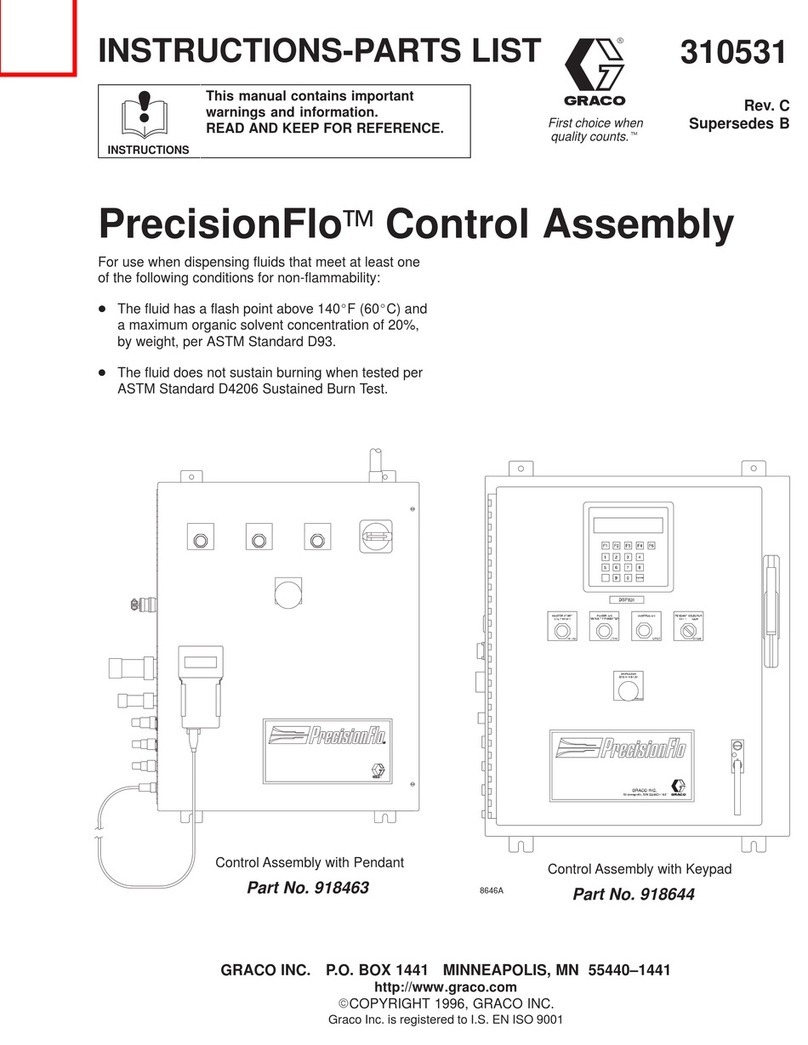

25A693Touchscreen

Box

Usedtomonitorandcontrol

functionsofthepaintkitchen

componentslocatedinside

thehazardouslocation.The

operatorusestheTouchscreen

interfacetoviewandremotely

controlconditionsandsettings.

100–240VAC

25A830SupervisorBoxUsedtocommunicatebetween

thePumpControlModule,the

TankControlModule,Variable

FrequencyDrives/Inverters,and

theTouchscreenBox.Contains

thesoftwarecontrolsused

tomonitorandcontrolpaint

kitchencomponentsandsystem

performance.

100–240VAC

25A843ExpansionBoxOneormoreExpansionBoxes

areneededifthepaintkitchen

hasmorecomponentsthancan

tinsidetheSupervisorBox

25A830.

100–240VAC

ConformstoULSTD508A

CertiedtoCSASTDC22.2No.14

Notapprovedforuseinhazardous

locationsorexplosiveatmospheres.

23A4030C