INSTRUCTIONS-P

ARTS LIST

307–961

Rev

A

PUMP

P

ACKING KIT 222–687

For

Use In Displacement Pump 222–688

Pressure Relief Procedure

To

reduce

the risk of serious bodily injury

, includ

-

ing

fluid injection, splashing fluid or solvent in the

eyes

or on the skin, or injury from

moving parts or

electric shock, always follow this procedure

whenever you shut off the sprayer, when check-

ing or servicing any part of the spray system,

when installing, cleaning or changing spray tips,

and

whenever you stop spraying.

1.

Engage the gun safety latch.

2.

Turn the ON/OFF switch to OFF.

3.

Unplug the power supply cord.

4.

Disengage

the gun safety latch. Hold a

metal

part

of the gun firmly to the side of a grounded

metal

pail, and trigger the gun to relieve pres

-

sure.

5.

Engage the gun safety latch.

6. Open

the pressure drain valve, having a con

-

tainer

ready to catch the drainage. Leave the

valve

open until you are ready to spray

again.

If you suspect that the spray tip or hose is com-

pletely clogged, or that pressure has not been

fully

relieved after following the steps above,

wrap

a rag around the tip guard retaining nut or hose

end

coupling and VER

Y SLOWL

Y

loosen the part

to relieve pressure gradually, then loosen com-

pletely.

Now clear the tip or hose.

WARNING

1. Flush

the

pump, if possible. Follow the

Pressure

Relief

Procedure W

arning

, above.

2. Disassemble the pump. Clean and inspect all

parts for wear or damage and replace parts as

needed.

Coat the rod and the inside

of the cylin

-

der

with oil before reassembling.

NOTE: All

sprayers with DC/Brush-T

ype Motors:

When

replacing the pump packings, also in

-

spect the motor brushes and replace them,

if necessary.

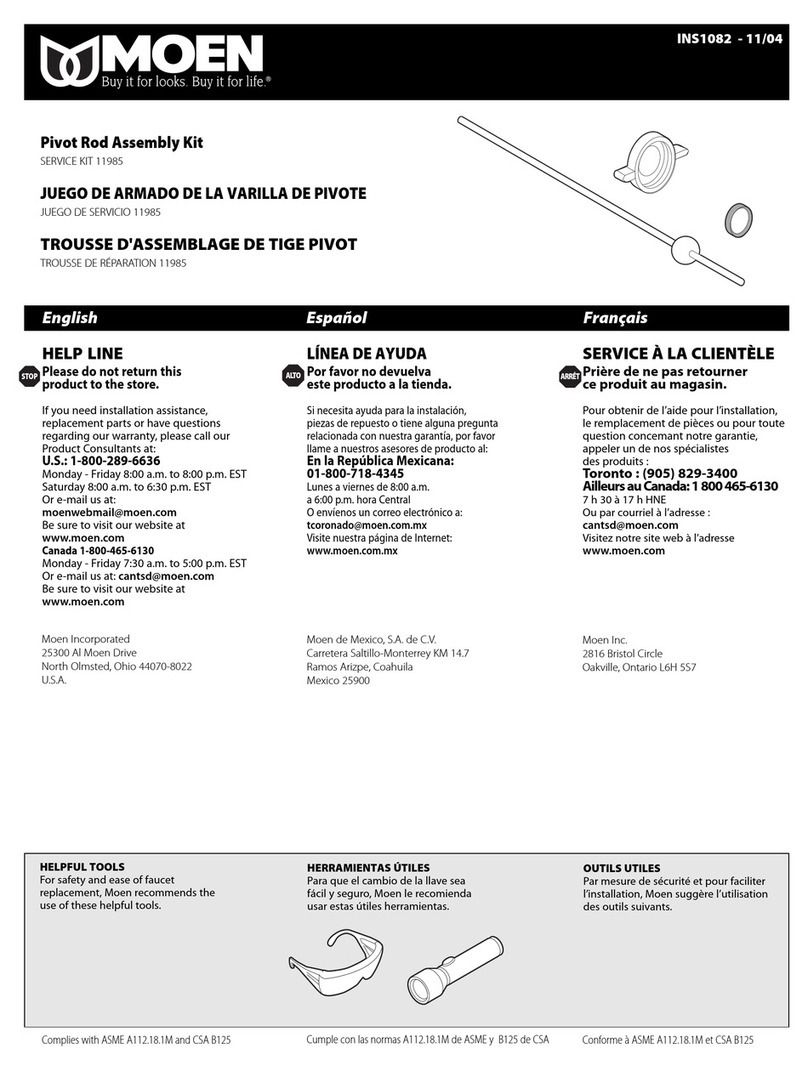

3. Stack the backup washer (19), seal (5), female

gland (20), packings (17) and male gland (13)

onto

the piston valve (24).

T

ighten the

nut (B) onto

the

valve to 10.5 in–lb (1.2 N.m) to seat the

pack

-

ings,

and then back of

f and tighten finger tight.

Note

the alignment

of the

piston valve (D) to the

nut

(B) and maintain this alignment through Steps

3,

4 and 5. This helps ensure that the nut (B) does

not

overcompress and swell the packings, which

can

cause

them to be damaged when the piston

assembly

is installed in the cylinder

.

GRACO INC. P.O. BOX 1441

MINNEAPOLIS, MN

55440–1444

COPYRIGHT

1989, GRACO INC.

This

manual contains

IMPORTANT

INSTRUCTIONS and WARNINGS.

READ AND RETAIN FOR REFERENCE.

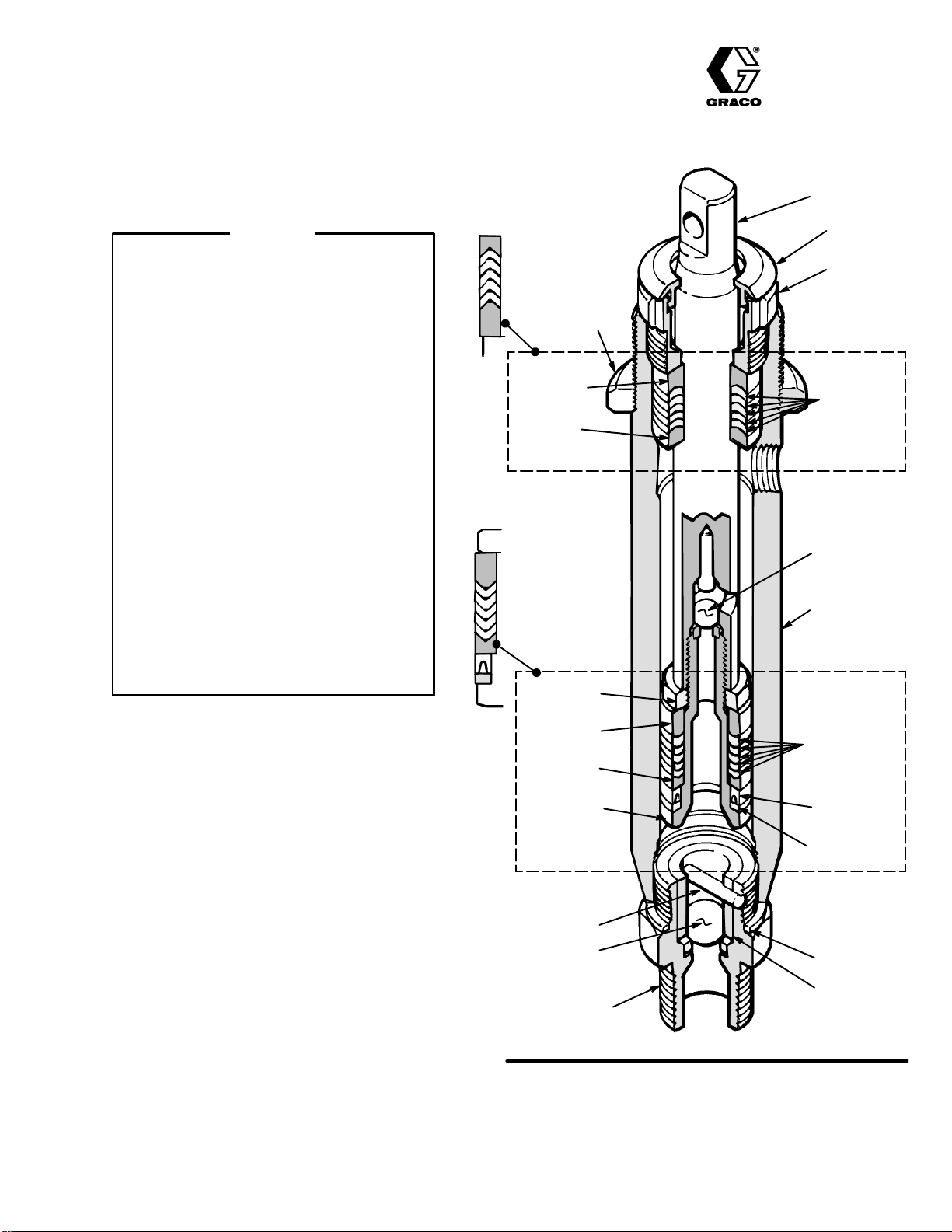

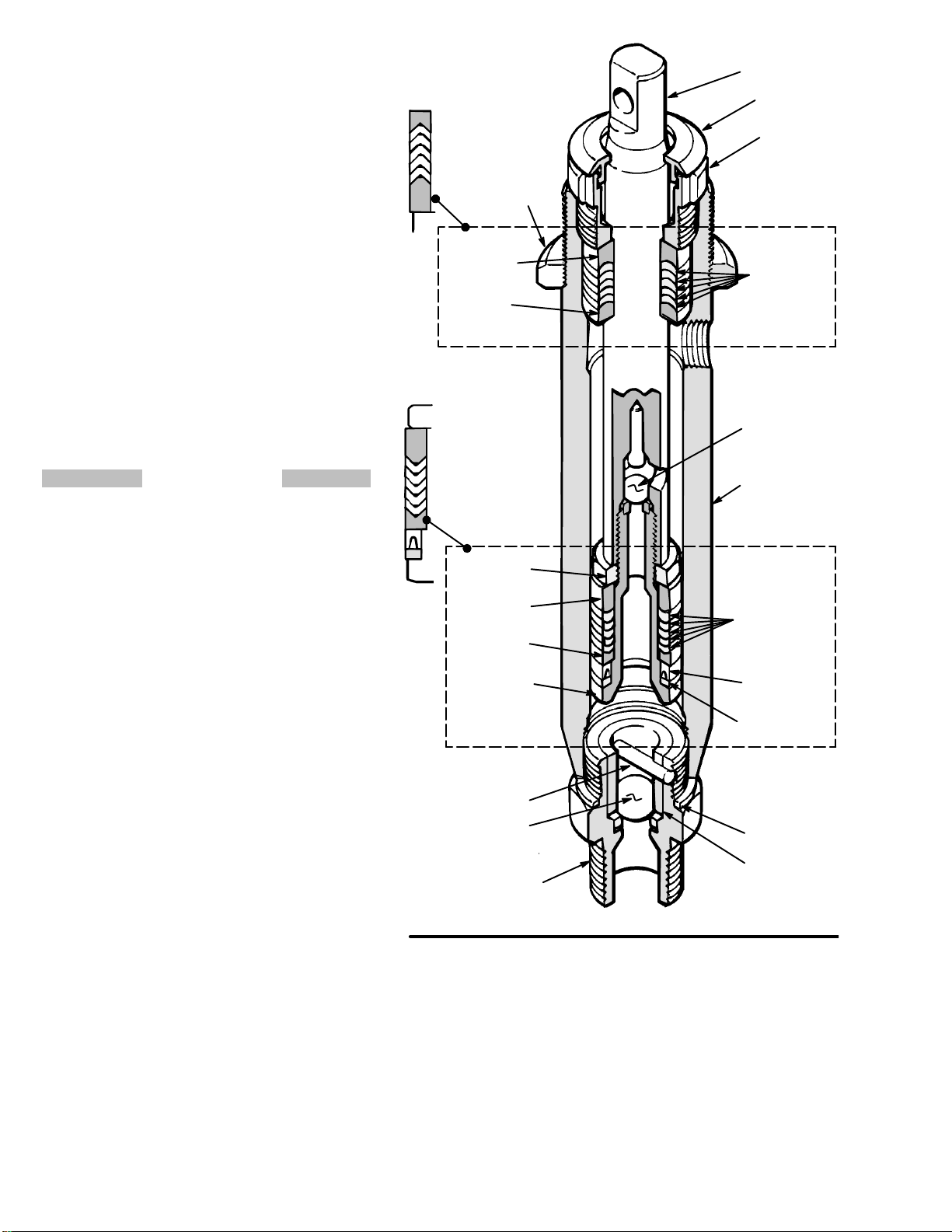

LIPS

OF

V–PACKING IN

THROAT MUST

FACE DOWN

DETAIL

OF

THROA

T P

ACKINGS

DET

AIL OF

PISTON PACKINGS

Fig

1

B

F

18

17

POLY

H

13

5

U-CUP SEAL

LIPS FACE DOWN

19

D

6

4

J

7

3

E

G

12

11

20

ROD

PACKING

NUT

JAM NUT

FEMALE

GLAND

MALE

GLAND

SMALL BALL

CYLINDER

PISTON NUT

MALE GLAND

BACKUP WASHER

GASKET

BALL GUIDE

LARGE BALL

PIN

PISTON

VALVE

FEMALE

GLAND

INTAKE VALVE

LIPS OF

V–PACKING IN

THROAT MUST

FACE DOWN

POLY

LIPS OF

V–PACKING IN

PISTON MUST

FACE UP

LIPS OF

V–PACKING IN

PISTON MUST

FACE UP

K

L

PLUG