4 308-092

Operation

WARNING

MOVING P

ARTS HAZARD

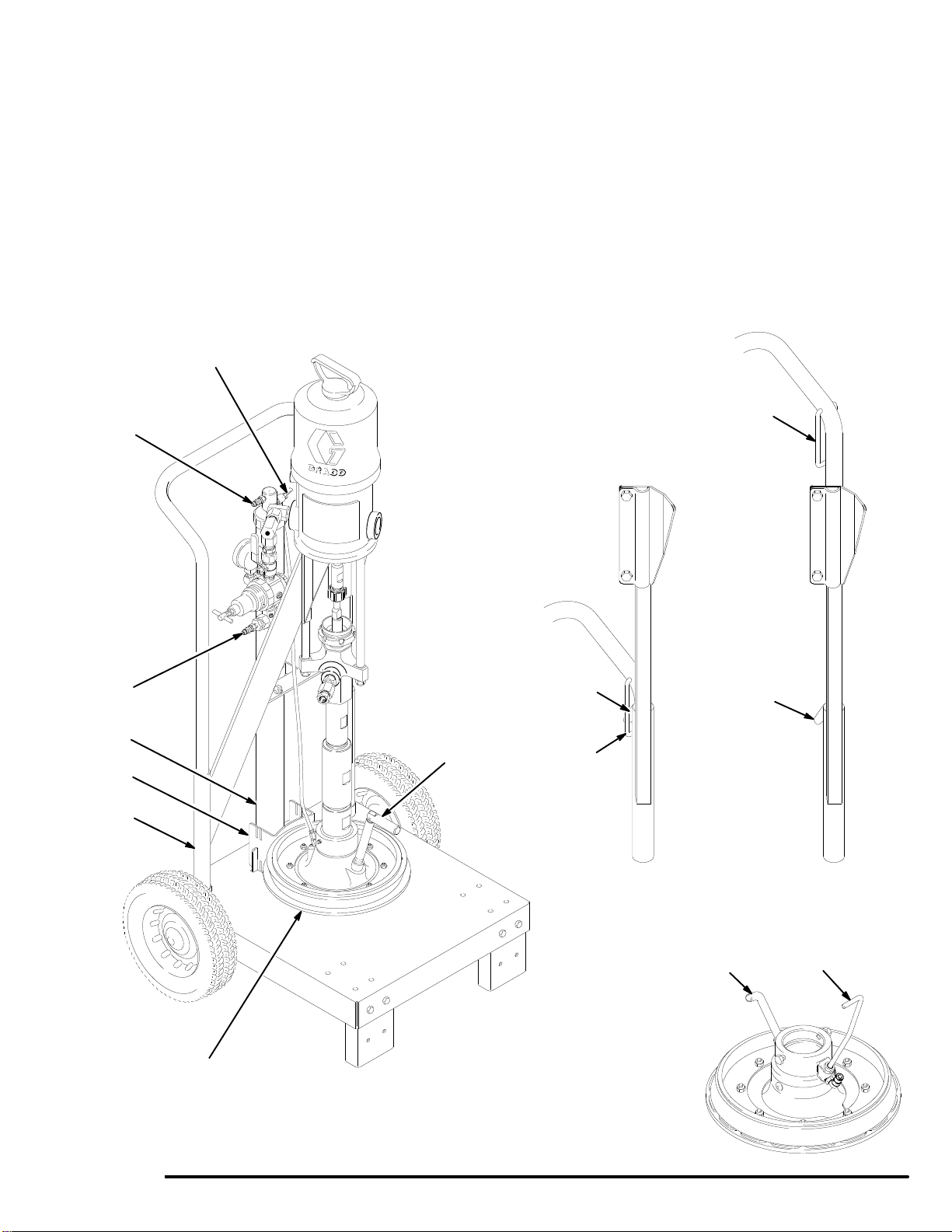

The elevator tube (F) and frame slides

(G) move up and down when the eleva

-

tor is in operation, and can pinch fingers

or hands caught between them and the cart frame.

Keep your hands away from the elevator tube,

frame slides, and the frame of the cart when the

elevator is in operation. See Fig. 2.

The wiper plate (K) moves downward as the eleva

-

tor is lowered, and can pinch or amputate fingers or

hands caught between it and the lip of the fluid

container

. Keep your hands away from the wiper

plate and the lip of the fluid container when the

elevator is in operation. See Fig. 2.

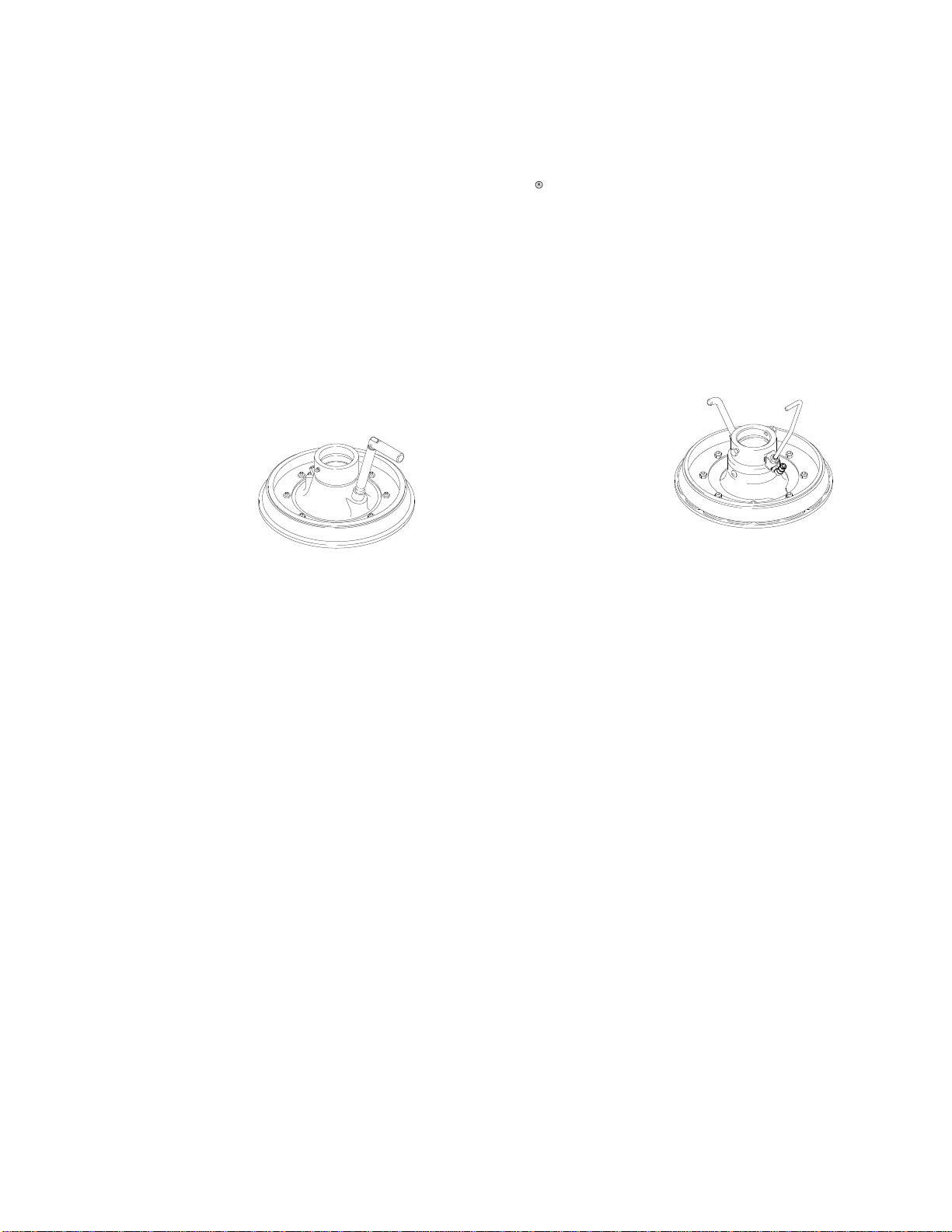

Wiper Plates 222–812 and 222–909

Wiper

plates 222–812 and 222–909 are shipped for

use with straight-sided pails on a 19 liter (5 gallon)

ram. The plates must be modified for use with this

pneumatic elevator cart, or for use with tapered pails.

Refer to the separate wiper plate manual 308–049 for

details.

Raising the Elevator and Positioning the

Pail

NOTE: T

o ensure smooth operation of the elevator

,

grease the vertical portions of the cart handle so the

frame slides (G) move up and down easily

.

1.

Disconnect the female quick coupler from the

pump air inlet fitting (L) and connect it to the air

inlet fitting (3n) on the elevator

. T

urn on the main

air

. See Fig. 2.

2.

Raise the elevator to its maximum height, so the

hanger (H) on the cart handle is below the hook (J)

on the elevator frame.

3.

Place a 19 liter (5 gallon) pail of fluid on the base

of the cart. Slide the pail back against the pail stop

(15). The pail stop is adjustable to four positions,

to properly align the pail with the wiper plate (K).

4.

Make the fluid surface concave by scooping fluid

from the center of the pail to the sides.

Lowering the Elevator

1. Pull

the hanger (H) upward and hold it firmly

against the handle of the cart. Disconnect the

female quick coupler from the elevator air inlet

fitting (3n) and connect it to the pump air inlet

fitting (L). After a short delay

, the weight of the

pump will cause the elevator to move downward.

Continue to hold the hanger (H) against the cart

handle until the hook (J) on the frame is low

enough to prevent it from engaging the hanger

.

See Fig. 2.

2.

If necessary

, push down on the top of the pump to

help the wiper plate (K) enter the pail. When the

wiper plate enters the pail, open the wiper plate

vent (M) and leave it open until fluid appears at the

vent hole. Close the vent.

3.

Start the pump as explained in the separate pump

manual.

4.

When the pail is empty

, change pails as follows.

Changing Pails

To

raise the pump out of an empty pail:

WARNING

T

o reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

in your separate pump

manual.

1.

Stop the pump.

Relieve the pressure.

2.

Set the air release toggle valve (N) to the open

position (down). The toggle valve directs air under

the wiper plate, making it easier to pull the plate

out of the pail. See Fig. 2.

3.

For Stainless Steel W

iper Plate 222–909 only:

Rotate the long handle (P) in the wiper plate

housing 45

clockwise

and pull the handle up

-

ward (it should travel about 1/2 inch up and down).

This opens a passage for air to assist in getting

the plate out of the pail. See the Detail in Fig. 2.

4.

Disconnect the female quick coupler from the

pump air inlet fitting (L), and connect it to the

elevator air inlet fitting (3n). After a short delay, the

elevator will begin to raise the pump from the pail.