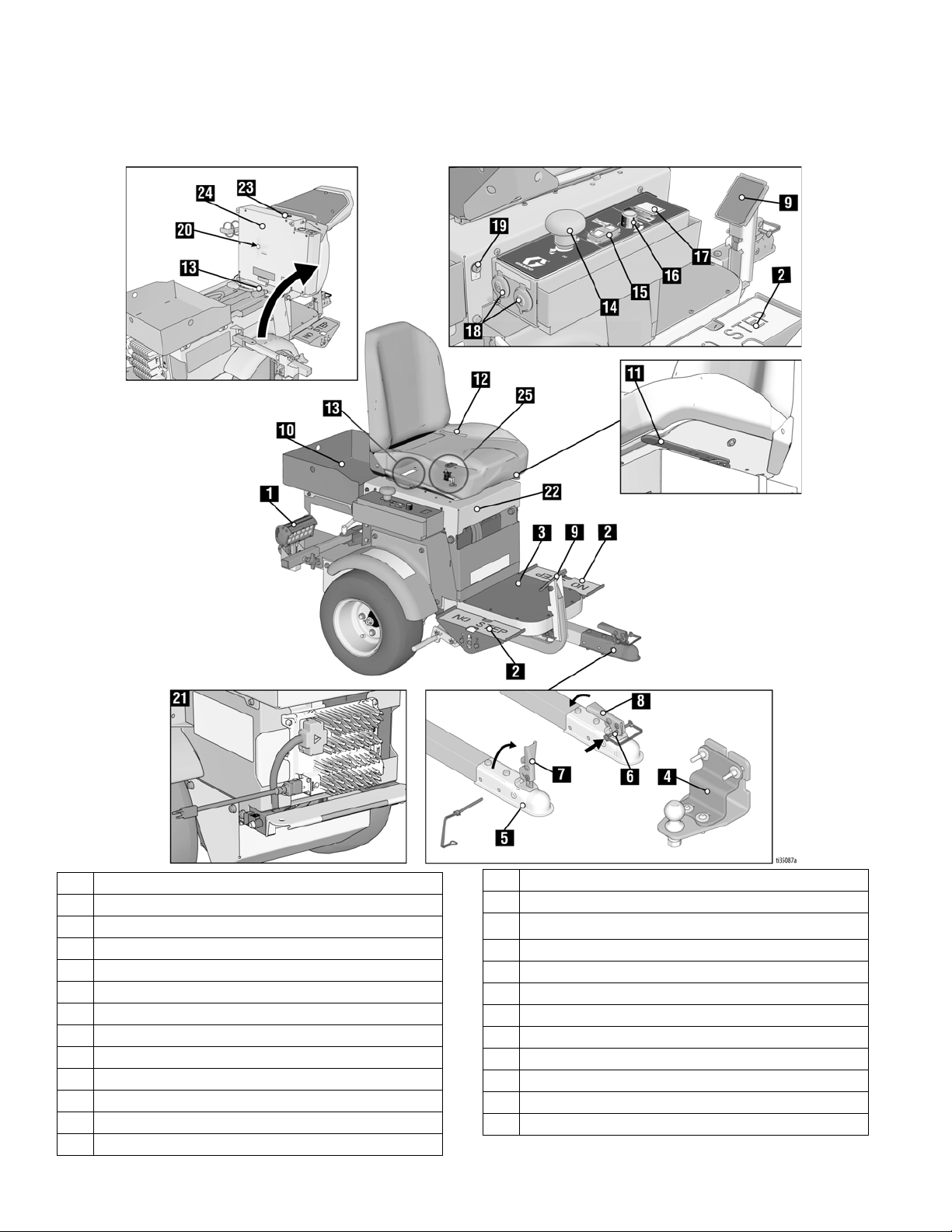

Operation

10 3A6623D

7. Engage Parking/Emergency Brake when not oper-

ating LineDriver. This prevents rolling when on an

incline.

Operating on Inclines

Extended Braking Distance

Operating on inclines results in extended braking dis-

tances.

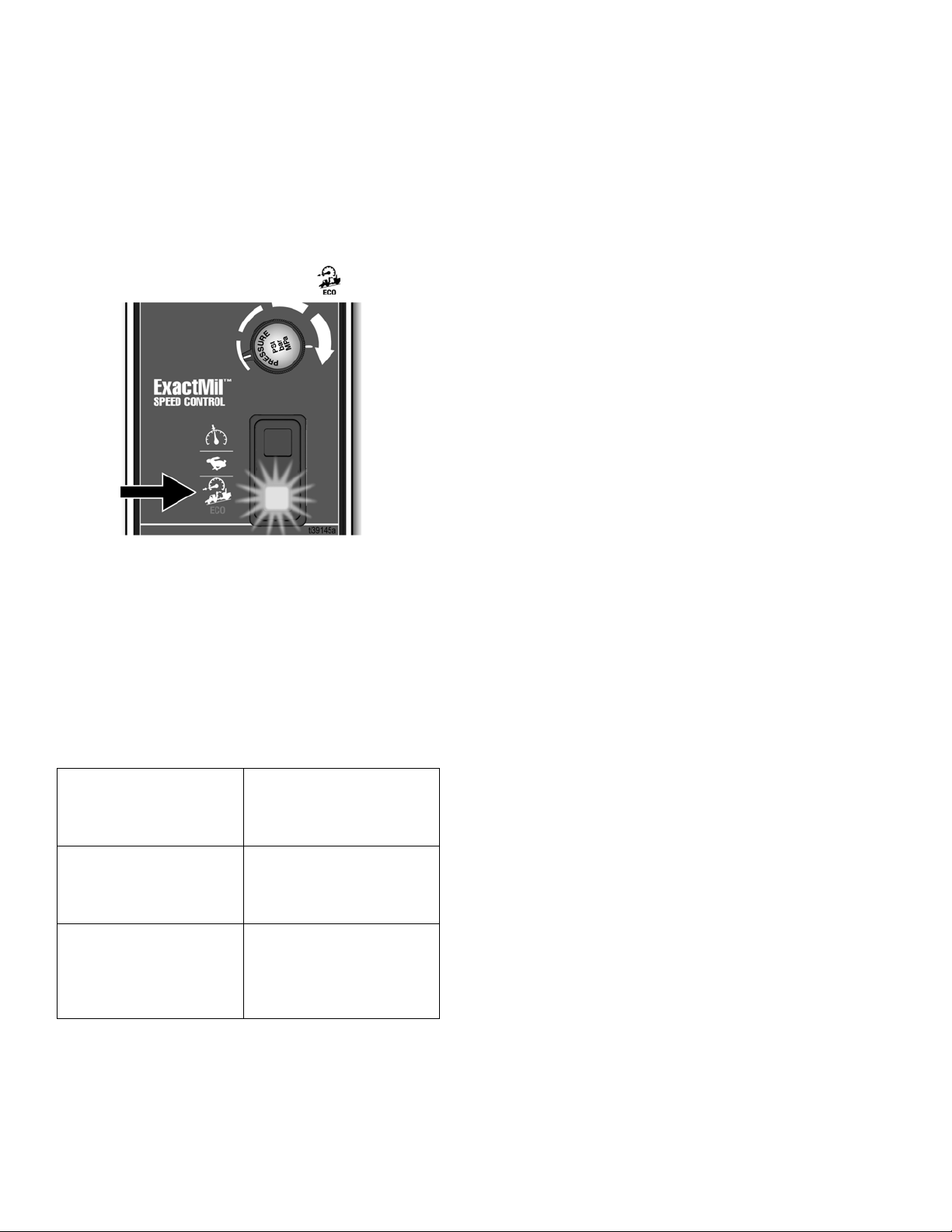

1. Select Incline/ECO mode on Speed Switch when

operating on inclines.

2. Be prepared to use the Parking/Emergency Brake

when operating on inclines.

NOTE: Do not operate on inclines greater than 7.5

°

(13%).

Starting and Stopping on an Incline

1. Engage the Parking/Emergency Brake before turn-

ing the Power Switch to OFF when parking on an

incline.

2. Turn the Power Switch to ON, and allow the

machine to initialize before releasing the Park-

ing/Emergency Brake when starting on an incline.

Trailer Loading & Unloading

NOTE: LineDriver ES rolls freely, especially on inclines,

when the power is off. Set Parking/Emergency Brake

before turning off. Turn power on before releasing Park-

ing/Emergency Brake.

1. Always keep LineDriver connected to striper or

grinder.

2. Use a level surface to load and unload. Leave suffi-

cient space behind ramps.

3. Use loading ramps of sufficient length and capable

of handling weight of unit and operator.

4. Adjust striper or grinder handlebar to highest posi-

tion. Slide seat back as far as possible.

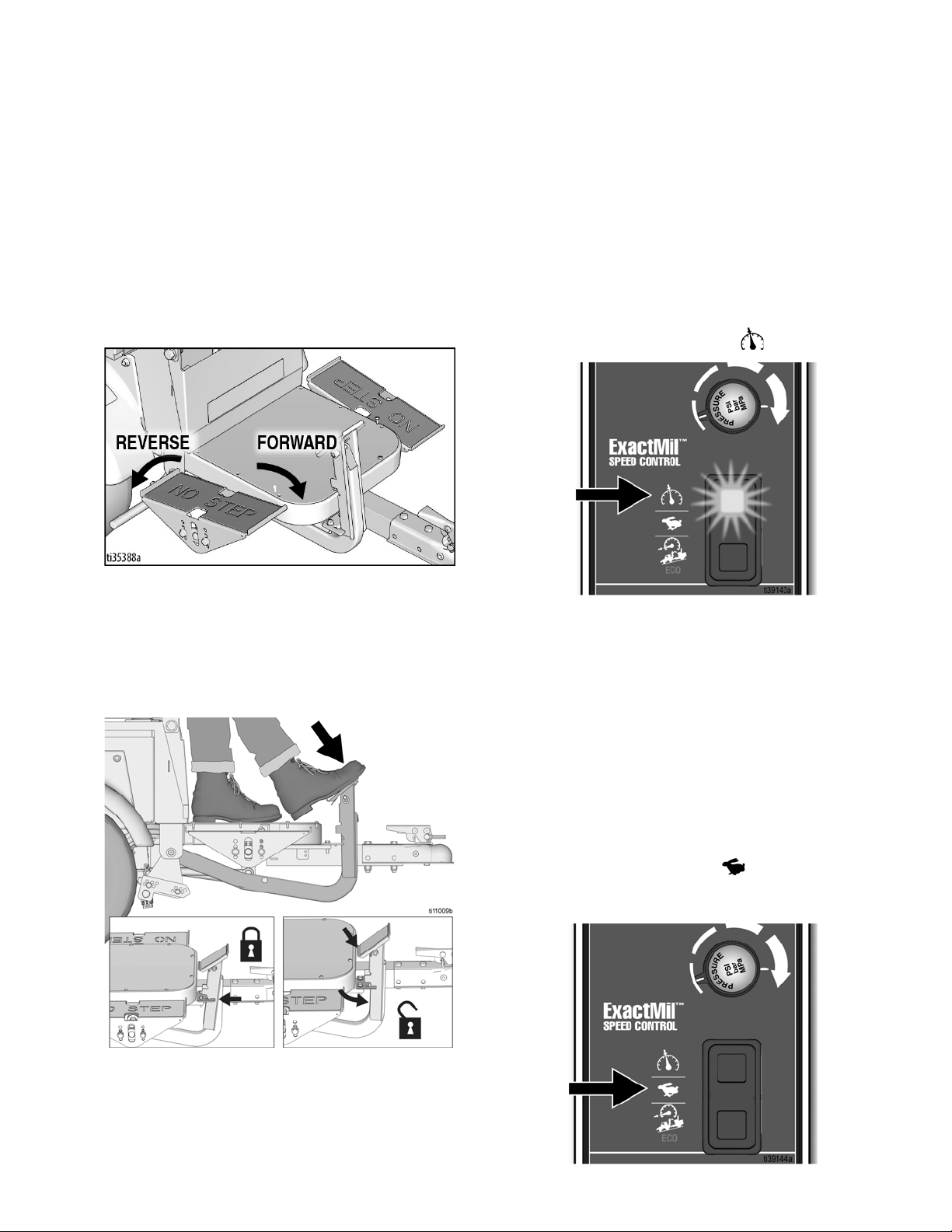

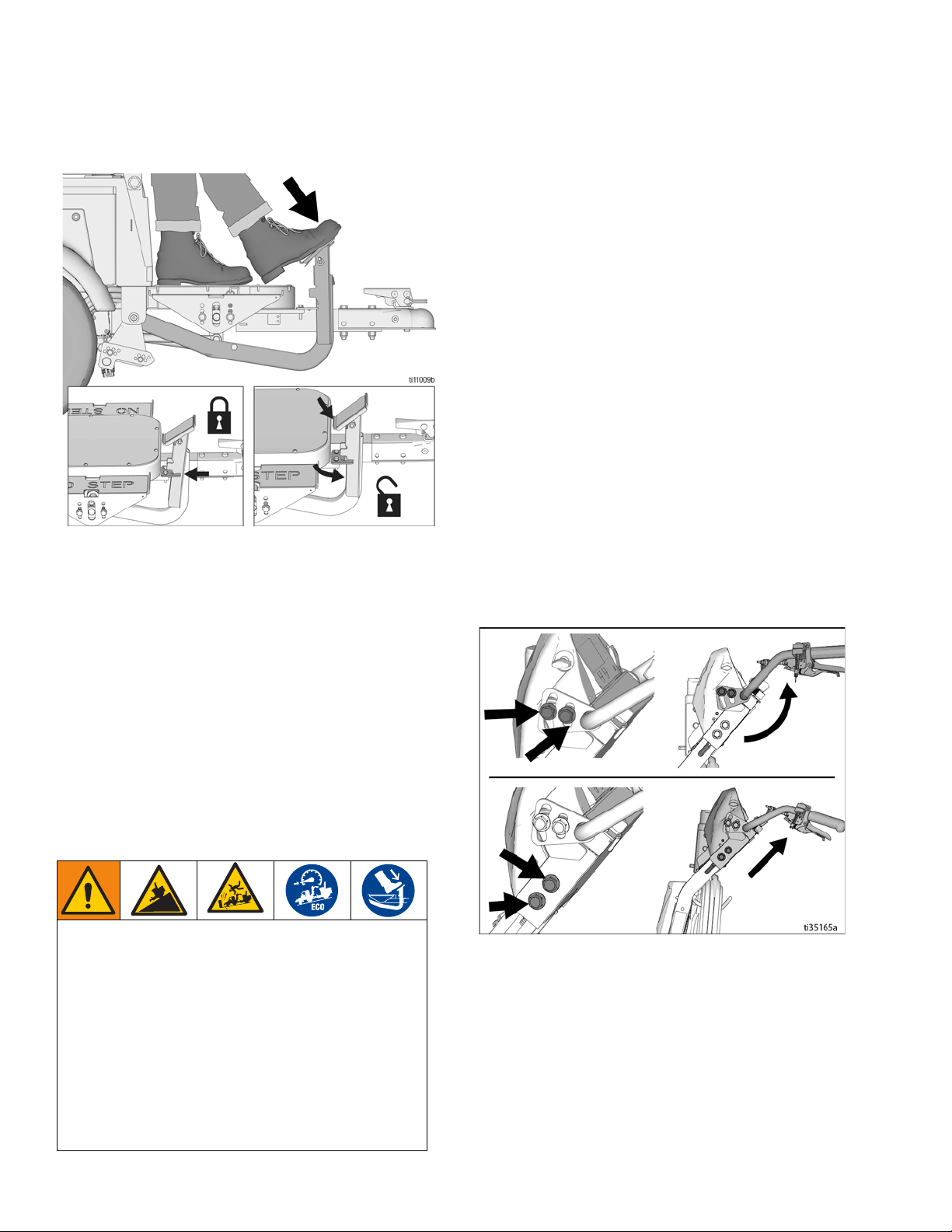

5. Use right foot to engage Parking/Emergency Brake.

Use left foot to control speed. Use ECO Mode to

limit speed.

6. Slowly drive straight up/down ramps (do not drive at

an angle).

7. Keep a firm grip on handlebars as the ramp is nego-

tiated.

NOTE: Striper or grinder handlebars swing up/down as

the ramp is engaged/disengaged. Keep legs clear.

REDUCED BRAKING HAZARD

The braking from the Direction/Speed pedals can be

significantly reduced when going down inclines at

speeds over 6.5 mph (10 kph). This reduced braking

results in longer braking distance than normal, which

could lead to an accident.

A continuous buzzer alarm will sound when this

reduced braking condition occurs. If this alarm

sounds, apply the Parking/Emergency Brake to slow

down. Failure to do so could result in serious injury.

• Do not drive in a manner that causes this alarm to

sound.