Graco RTX-650 Programming manual

Other Graco Paint Sprayer manuals

Graco

Graco FinishPro II 395 User manual

Graco

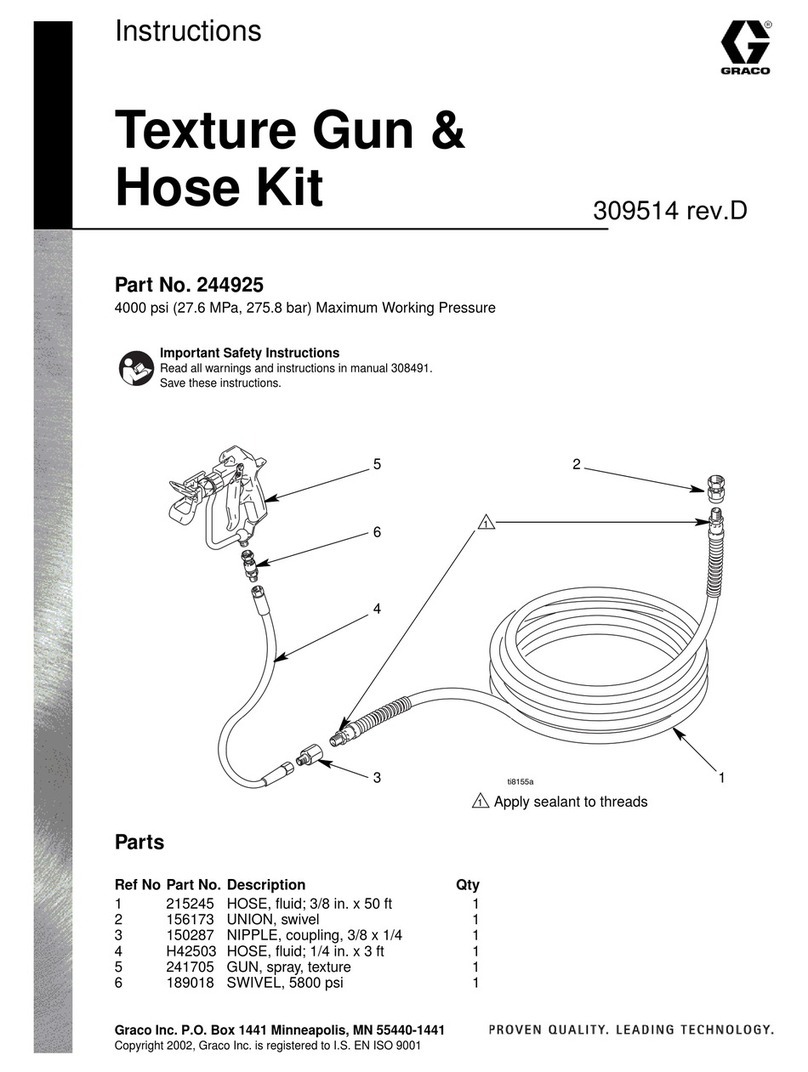

Graco 244925 User manual

Graco

Graco SaniSpray HP 65 Use and care manual

Graco

Graco HFR Manual instruction

Graco

Graco 257025 Instruction Manual

Graco

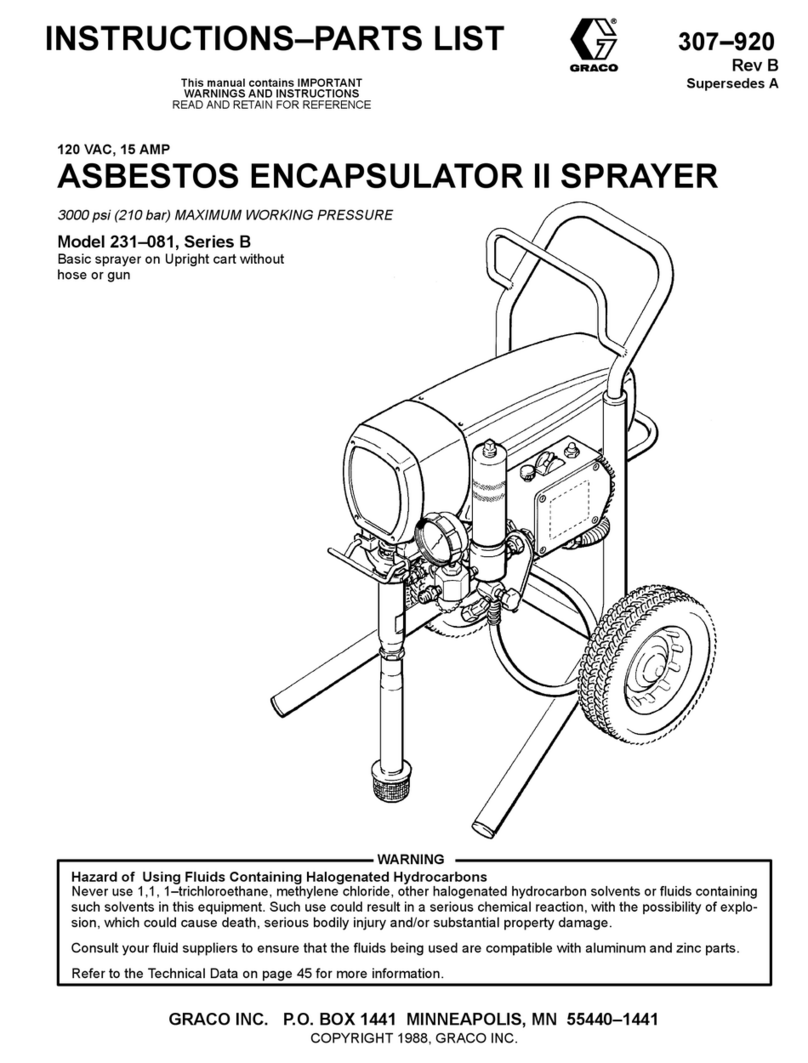

Graco 231-081 Datasheet

Graco

Graco Reactor E-10hp User manual

Graco

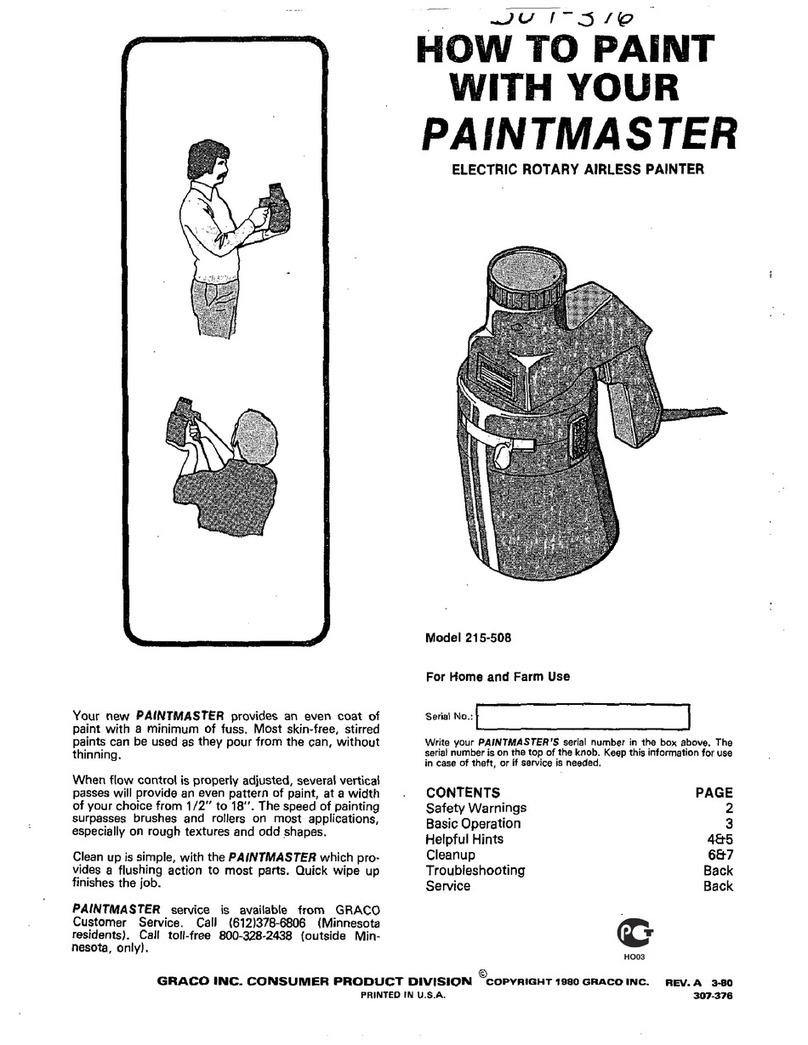

Graco 215-508 User manual

Graco

Graco Magnum Pro Compact A15 258861 User manual

Graco

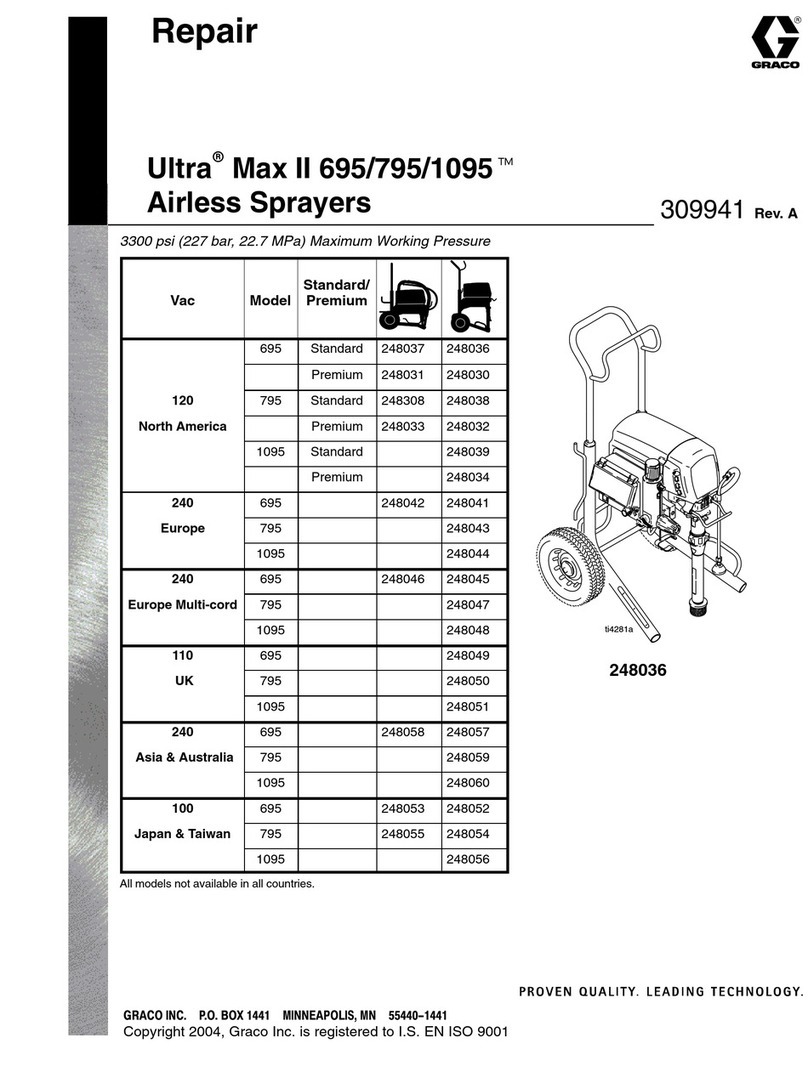

Graco 248037 Assembly instructions

Graco

Graco 695 HI User manual

Graco

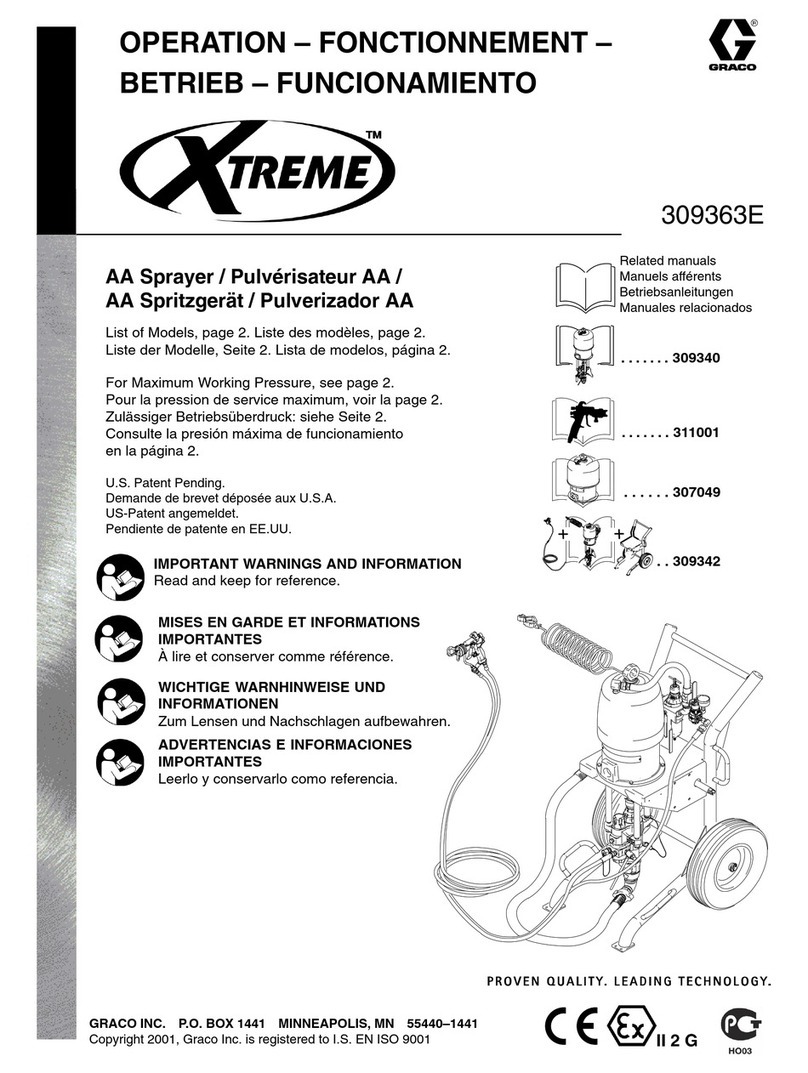

Graco Xtreme 309363E User manual

Graco

Graco 307-896 Operation manual

Graco

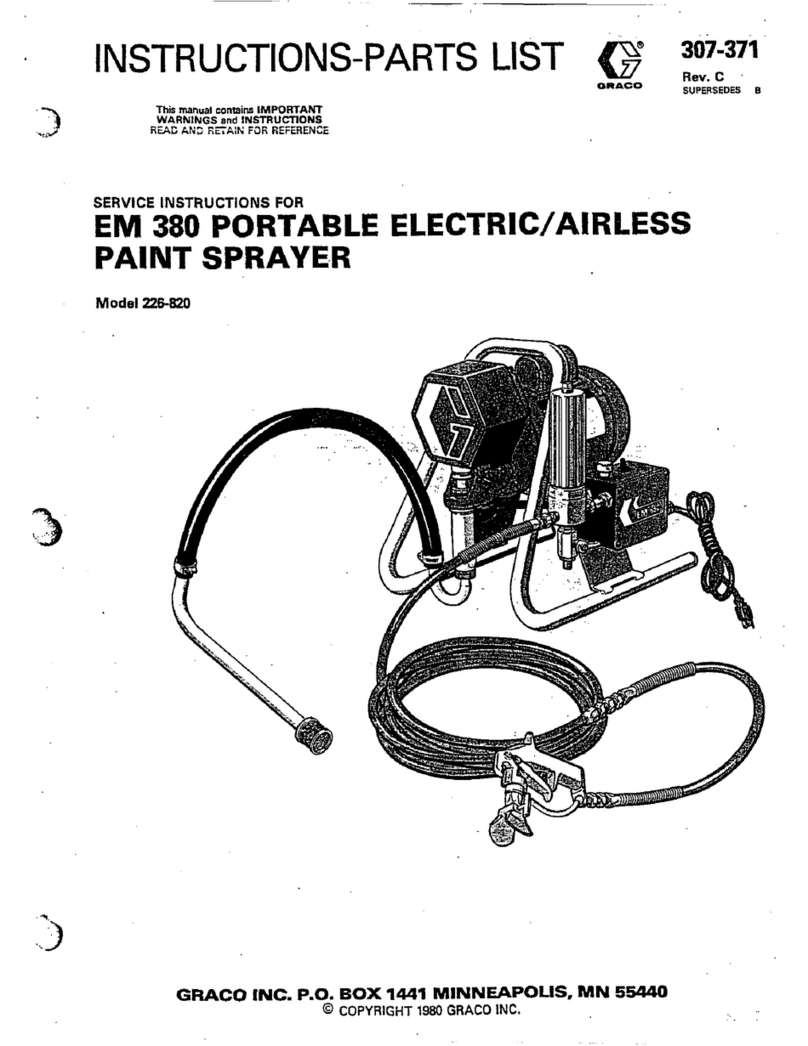

Graco EM 380 Operation manual

Graco

Graco EM 490R EM 490 Operation manual

Graco

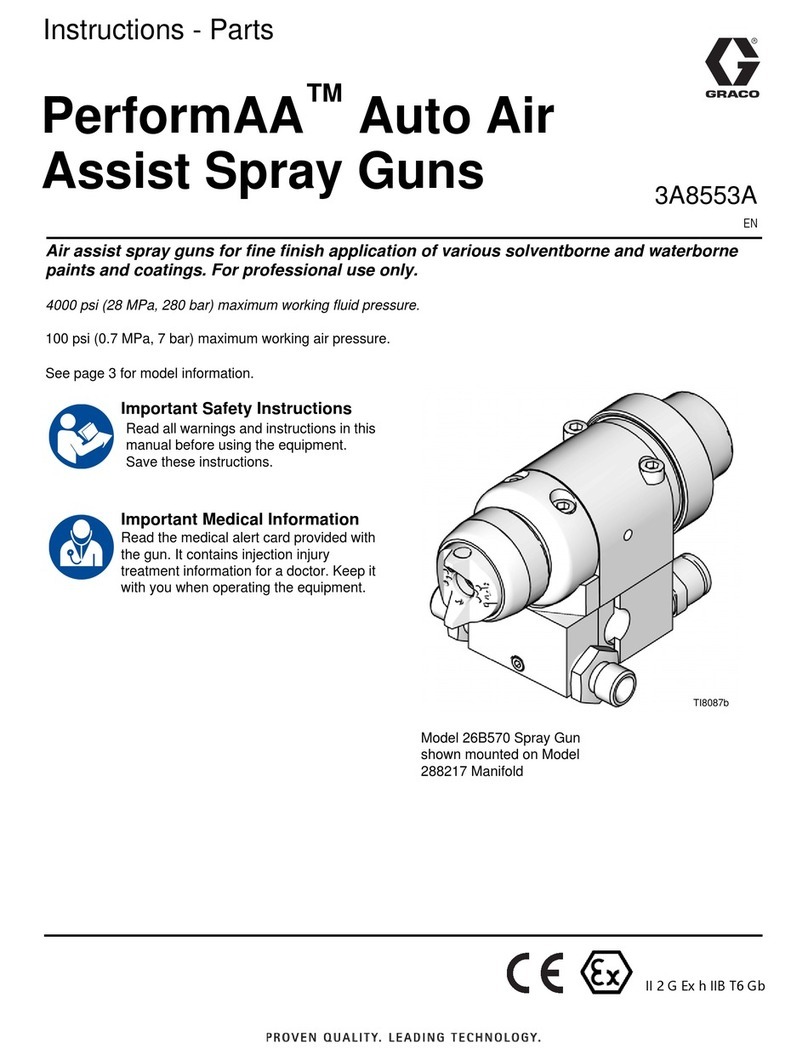

Graco PerformAA 26B570 User manual

Graco

Graco Ultra-lite 235627 Datasheet

Graco

Graco TrueCoat 360 User manual

Graco

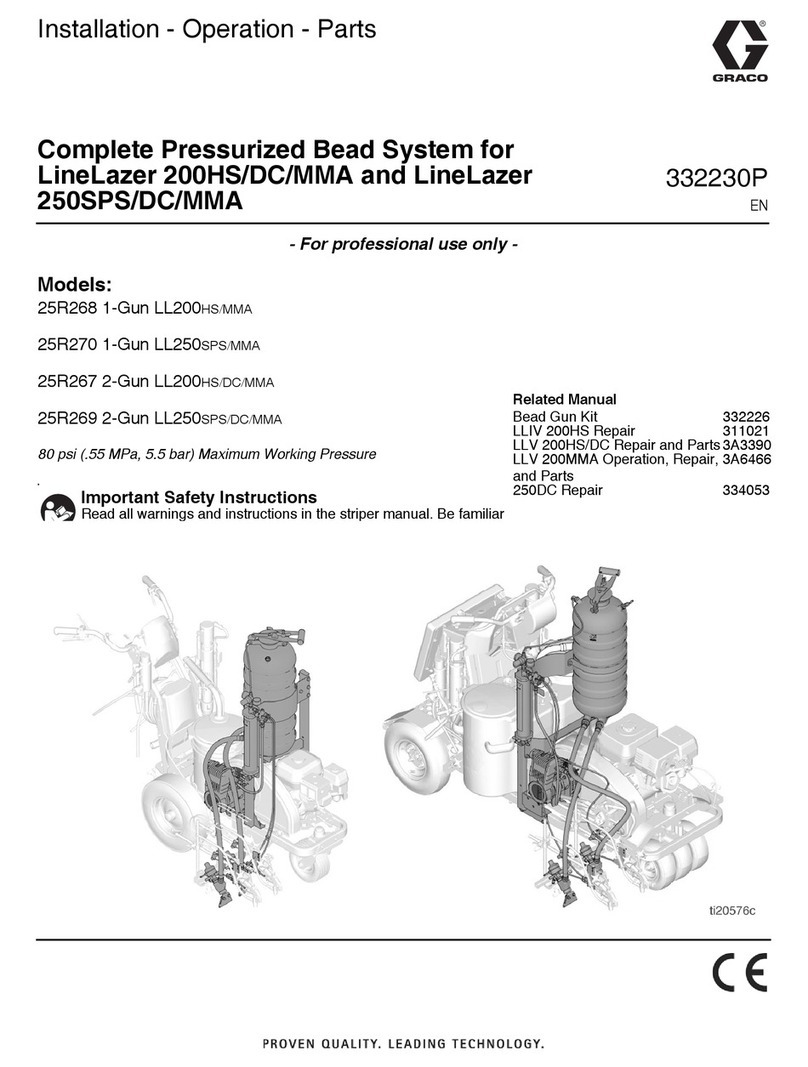

Graco 25R268 Guide

Graco

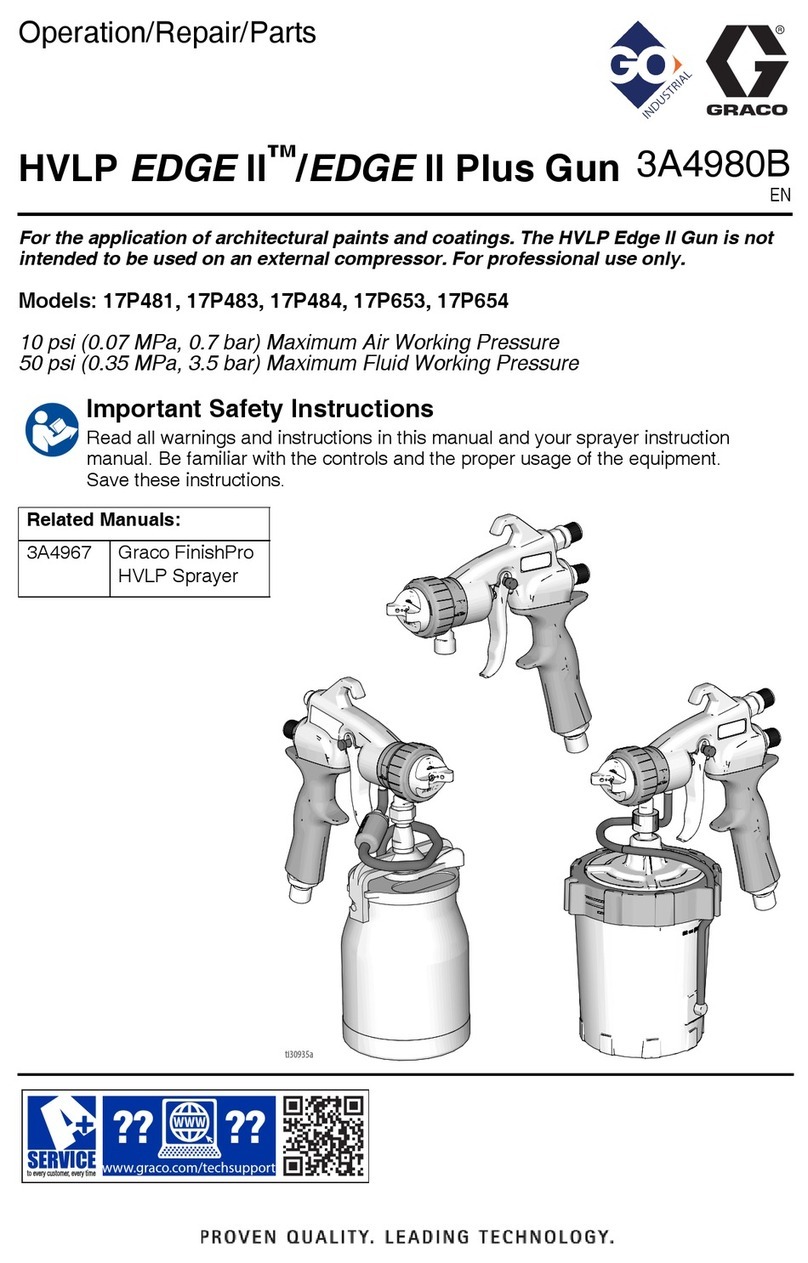

Graco 17P481 Use and care manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual