10 308-552

Troubleshooting

Pressure Relief Procedure

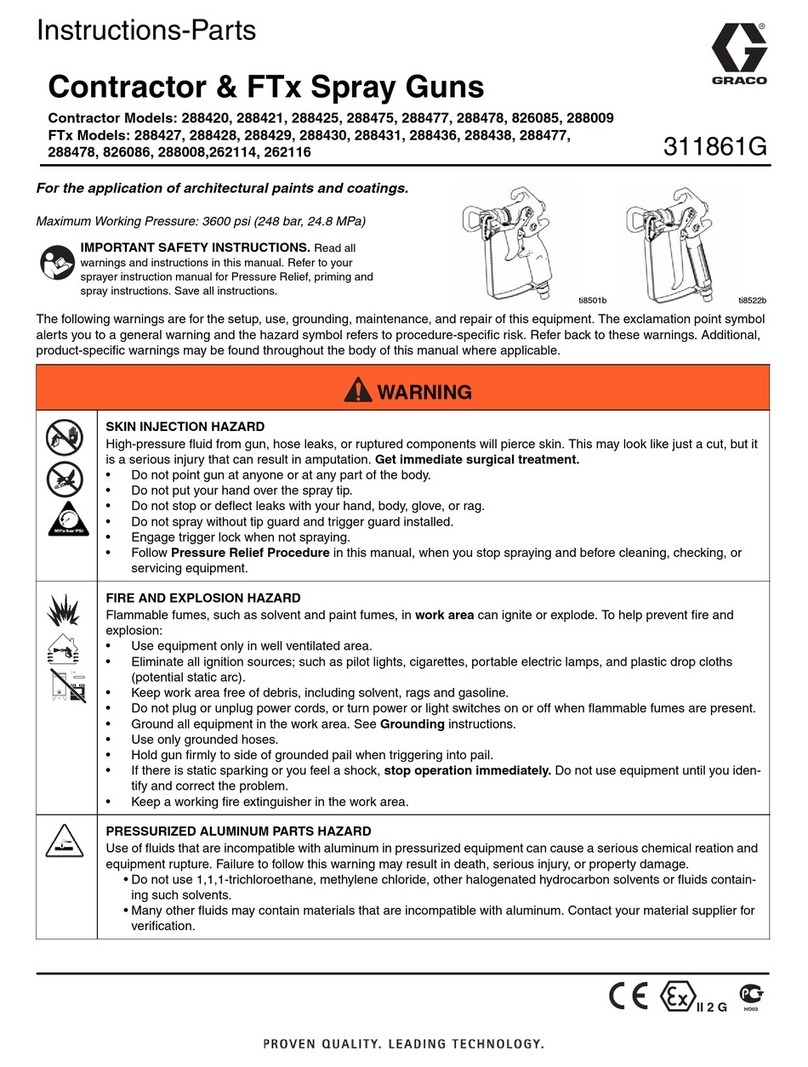

To

reduce the risk of serious injury

,

including fluid injec

-

tion,

injury from splashing fluid or

solvent in the eyes or

on

the skin, moving parts or electric shock, always fol

-

low this procedure whenever you shut off the

sprayer

,

when checking or servicing any part of the spray sys-

tem, when installing, cleaning or changing spray tips,

and

whenever you stop spraying.

1.

Engage the gun safety latch.

2. T

urn the ON/OFF switch to OFF

.

3.

Unplug the power supply cord.

4.

Disengage the gun safety latch. Hold a metal

part of the gun firmly to a grounded metal pail.

T

rigger the gun to relieve pressure.

5.

Engage the gun safety latch.

6.

Open the pressure drain valve. Leave the pres

-

sure drain valve open until you are ready to

spray again.

If you suspect that the spray tip or hose is completely

clogged,

or that pressure has not been fully relieved af

-

ter following the steps above

, VERY SLOWLY loosen

the tip guard retaining nut or hose end coupling to re-

lieve

pressure gradually

, then

loosen completely

. Now

clear

the tip or hose obstruction.

Check everything in the guide before disassembling the sprayer

.

TYPE OF PROBLEM WHA

T T

O CHECK

If check is OK, go to next check

WHA

T T

O DO

When check is not OK refer to this column

Building circuit breaker opens

Check all electrical wiring for damaged

insulation.

Replace any damaged wiring.

Check for other electrical appliances on

circuit.

Shutdown other electrical appliances on

circuit.

Check position of 10–12 (Lo–High) amp

switch.

Put switch in 10 amp (LO) position.

Sprayer circuit breaker opens

Check for locked motor rotor

. Unplug cord

and try to turn fan blades with a screwdriver

.

Repair gear train or pump, if damaged.

Thaw

the sprayer

, if frozen; See NOTE 1. Replace

the pressure control, if damaged.

Check for shorted motor

. Use ohmmeter to

check for shorts between motor leads or

between motor leads and motor frame.

Inspect for damage to motor brush leads.

Replace motor

, if necessary.

Check electrical supply with voltmeter

. Meter

should read 210–250 V

AC.

Connect to outlet of correct voltage.

Sprayer will not run

Check pressure control knob setting. Motor

will not run if it is at minimum setting (fully

counterclockwise).

Slowly increase pressure setting to see if

motor starts.

Check for a clogged spray tip. Refer to

separate gun or tip instruction manual.

Relieve pressure. Refer to separate gun or

tip instruction manual for tip cleaning.

Check extension cord for visible damage.

Use a volt meter or test lamp at extension

cord outlet to check.

Replace extension cord.

Check sprayer power supply cord for visible

damage such as broken insulation or wires.

Replace power supply cord.

Check electrical supply with volt meter

. Meter

should read 210–250 V

AC.

Reset building circuit breaker; replace

building fuse. T

ry another outlet.

Check for motor damage. Remove drive

housing assembly

. See page 17. T

ry to rotate

fan by hand.

Replace motor (1) if fan won’t turn.

Poor spray pattern

Check for worn spray tip.

Relieve pressure and then replace the tip.

See the separate gun or tip manual.