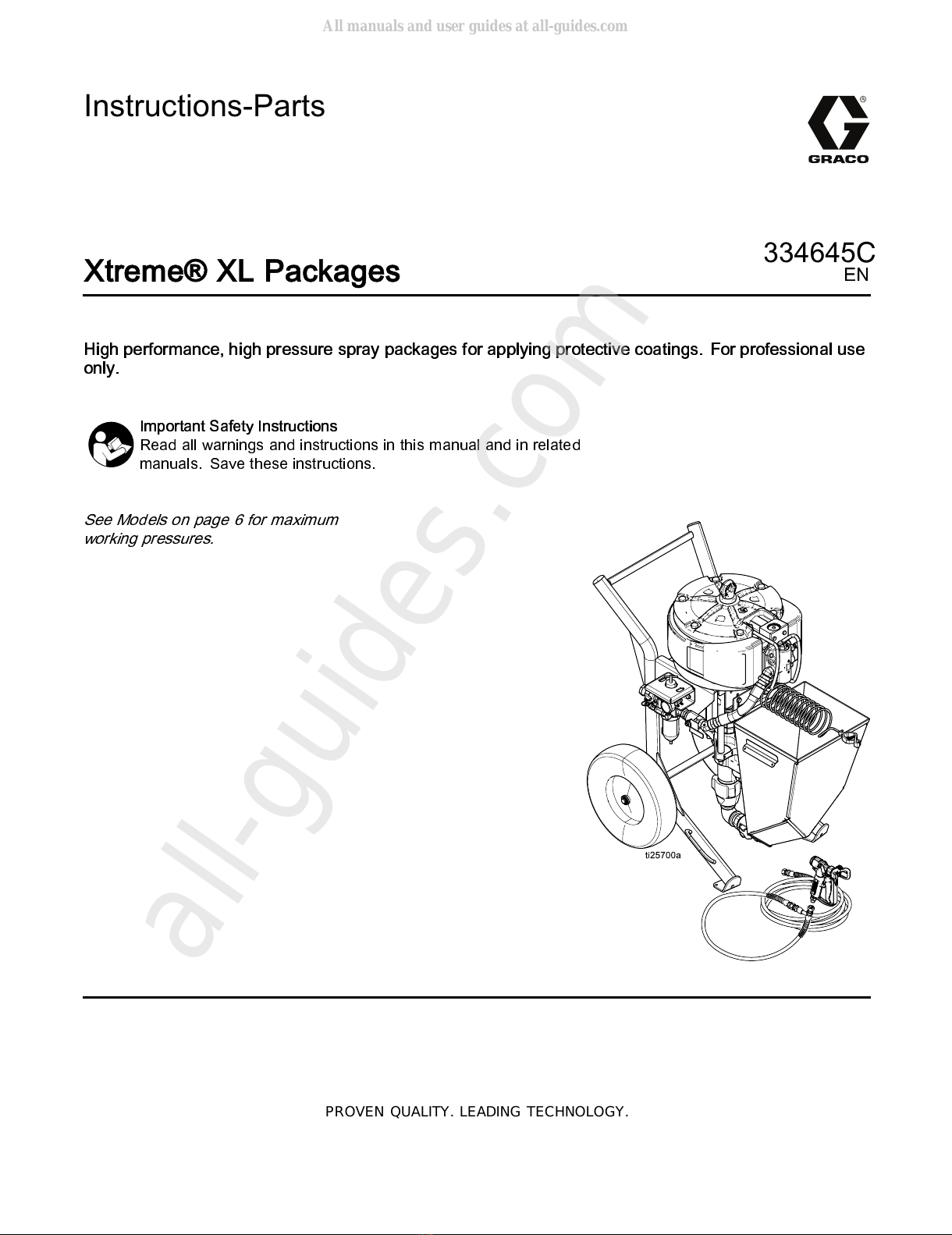

Graco Xtreme XL 45 Parts list manual

Other Graco Paint Sprayer manuals

Graco

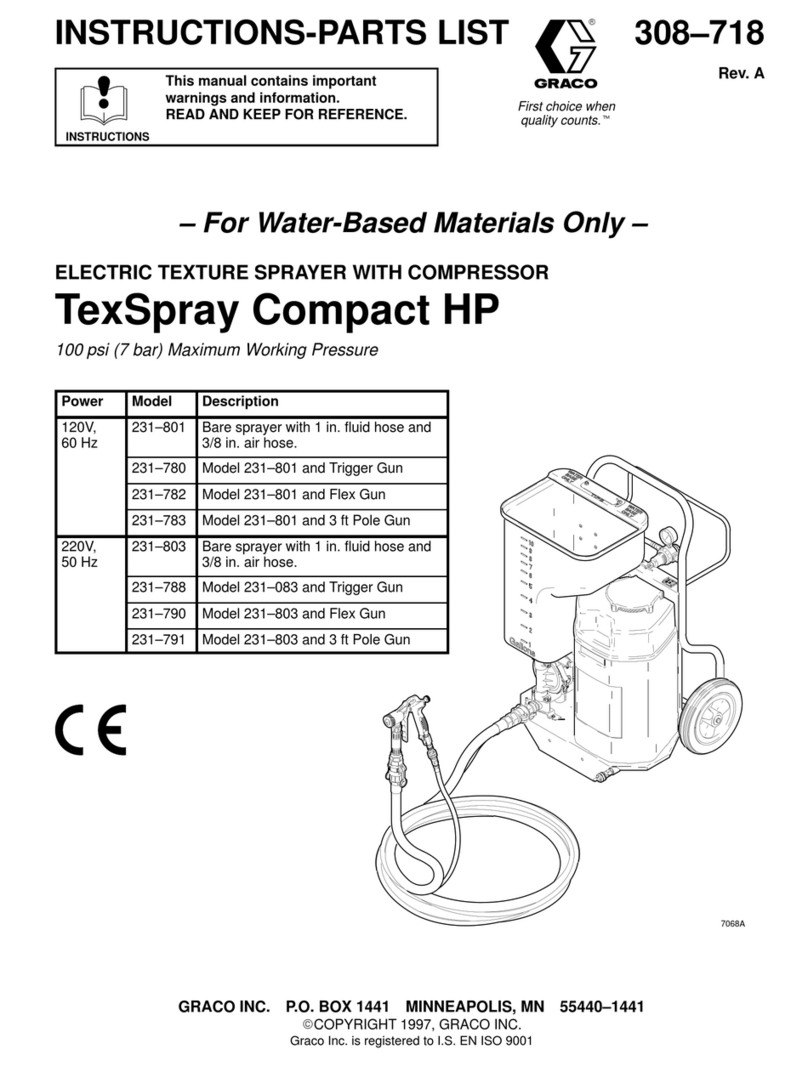

Graco TexSpray Compact HP 231-801 Operation manual

Graco

Graco RTX 900 Operating instructions

Graco

Graco 309489 User manual

Graco

Graco Reactor A-25 Use and care manual

Graco

Graco RTX2000 User manual

Graco

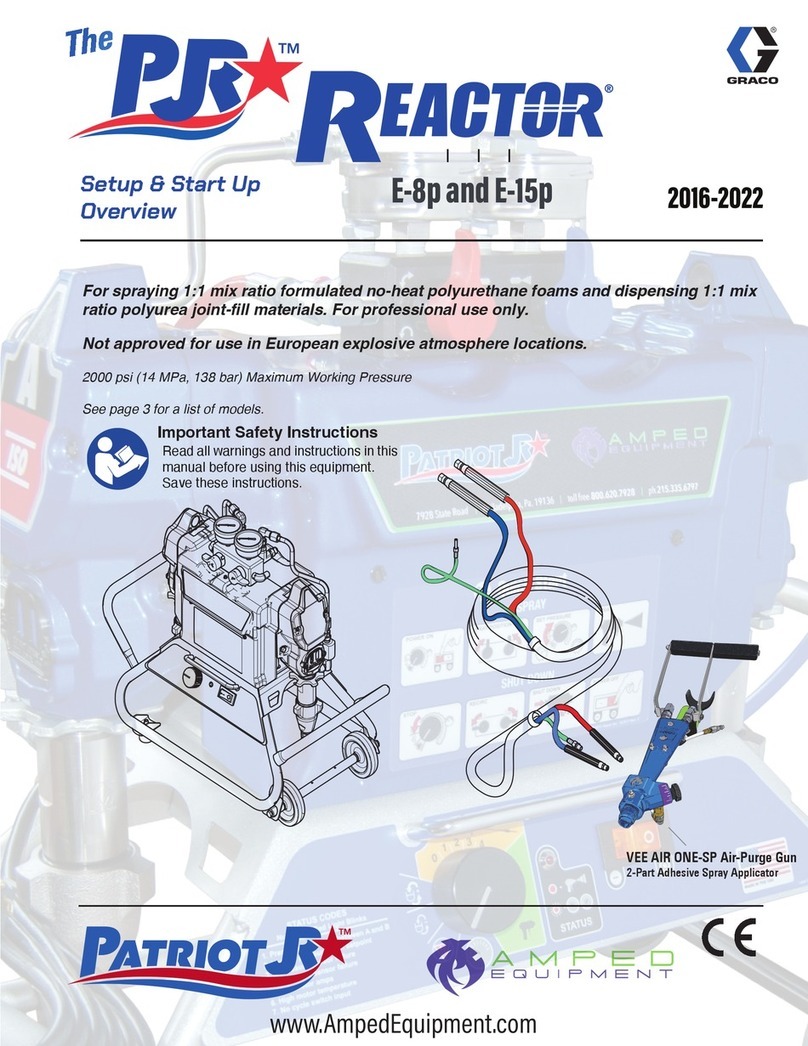

Graco PJR REACTOR E-8p Installation guide

Graco

Graco Fire-Ball A Series Operation manual

Graco

Graco HVLP TurboForce II 7.0 Manual

Graco

Graco RTX1400 Guide

Graco

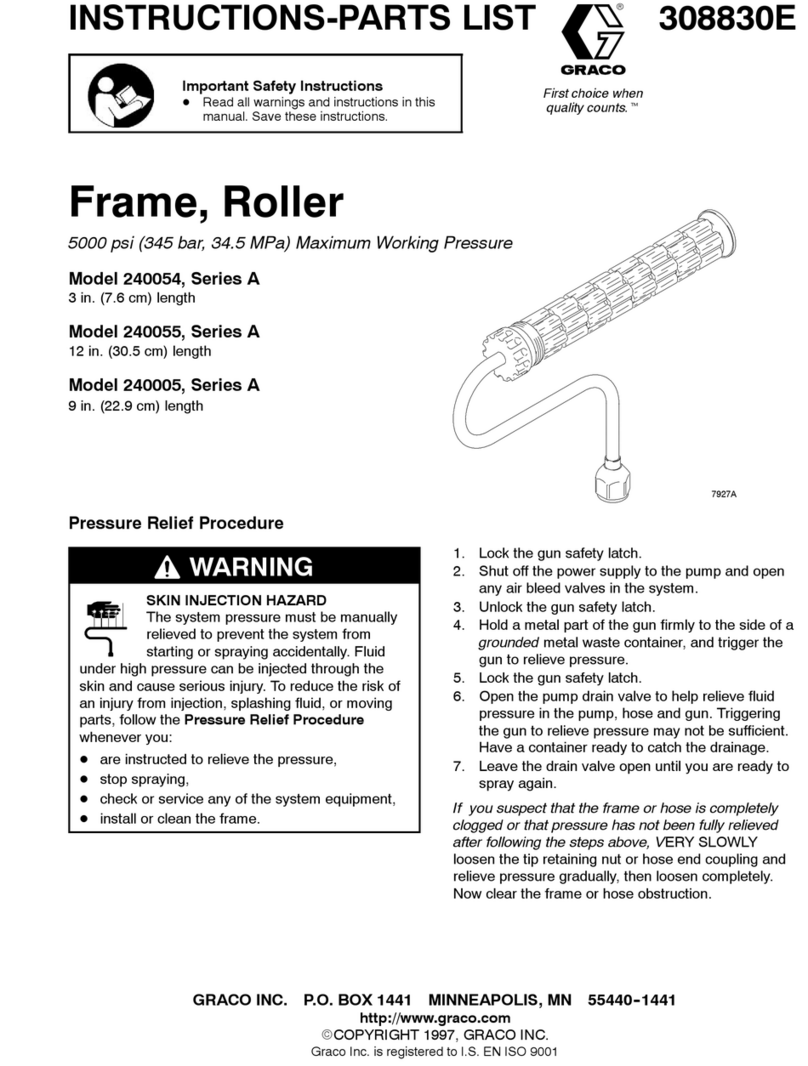

Graco 240054 Operation manual

Graco

Graco LineLazer II 3900 User manual

Graco

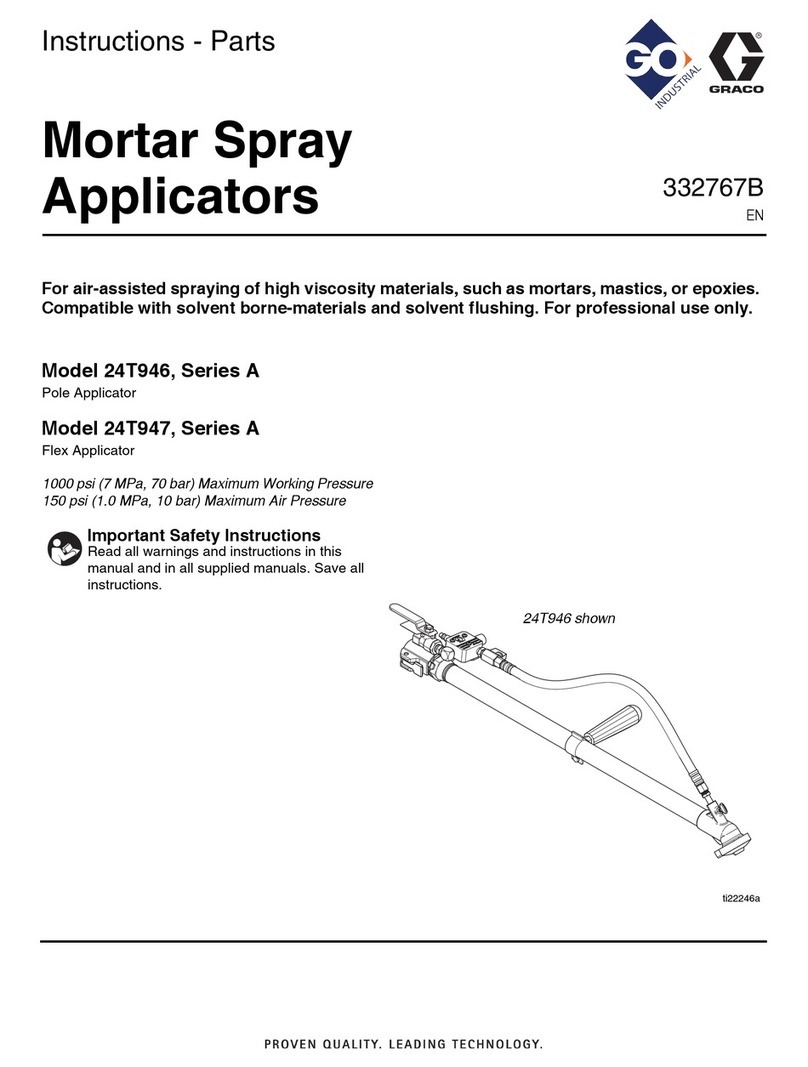

Graco 24T946 Operation manual

Graco

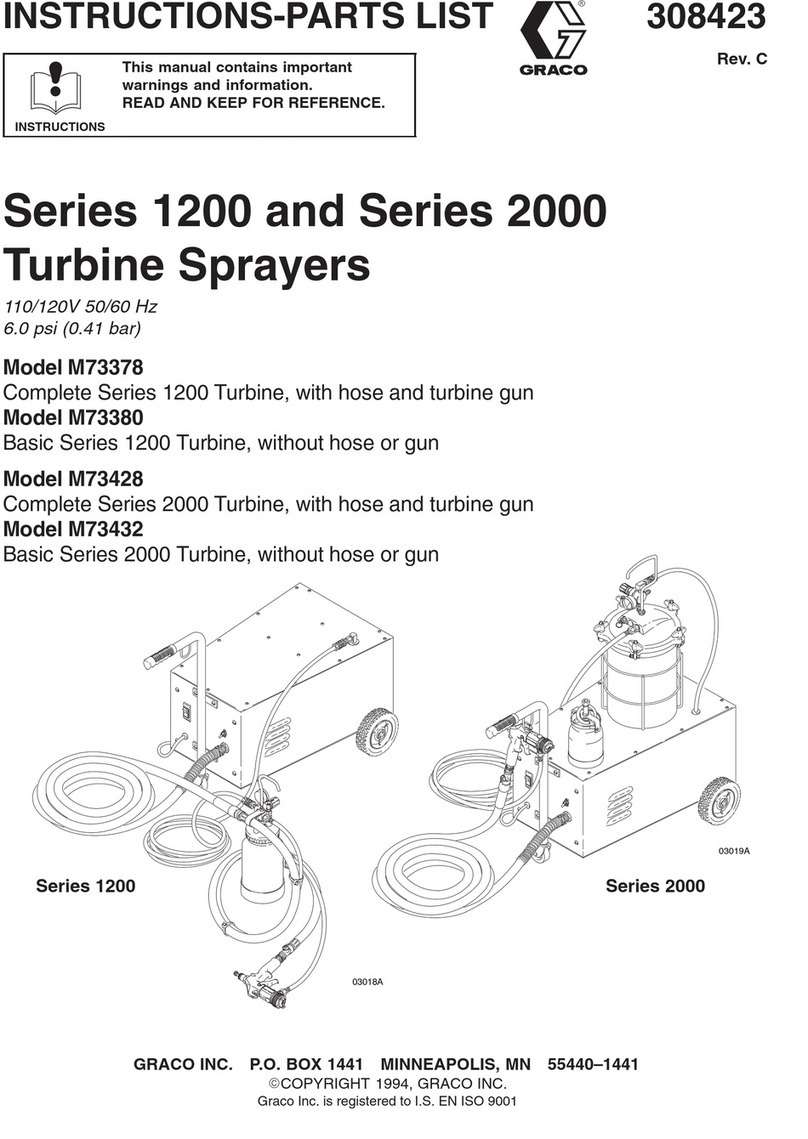

Graco M73380 Operation manual

Graco

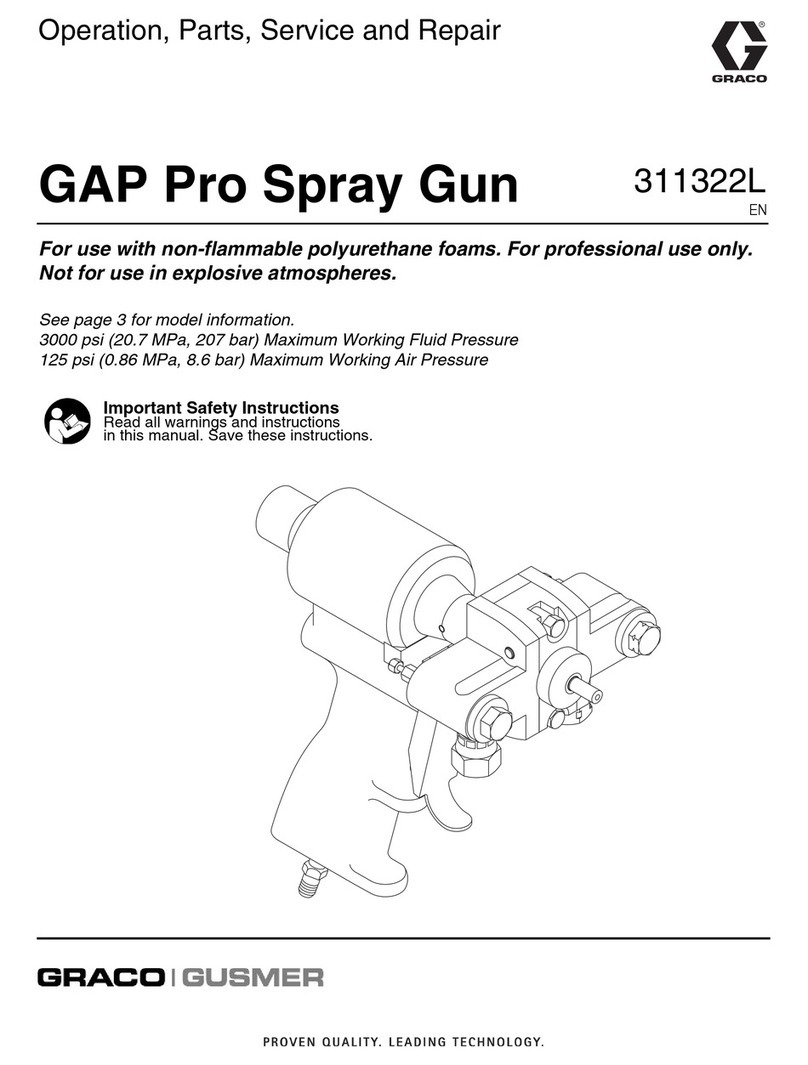

Graco 311322L Quick start guide

Graco

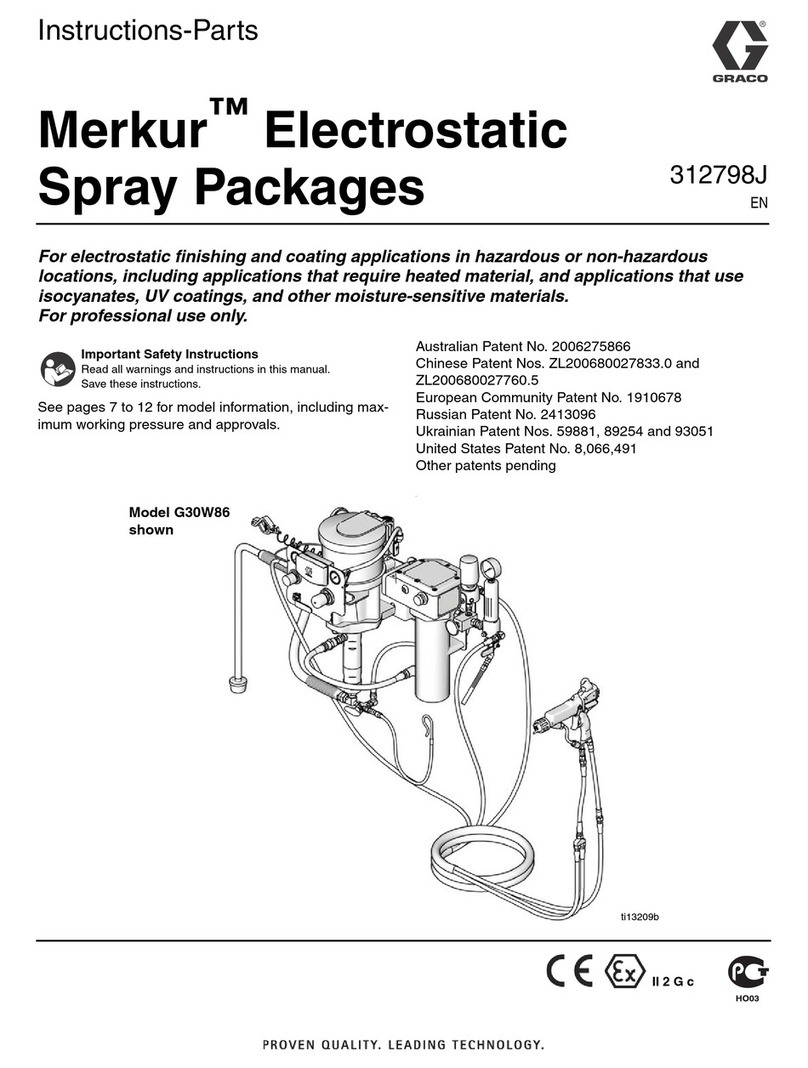

Graco Merkur G15W Series Parts list manual

Graco

Graco HYDRA-CLEAN C Series Operation manual

Graco

Graco SUPER NOVA SP User manual

Graco

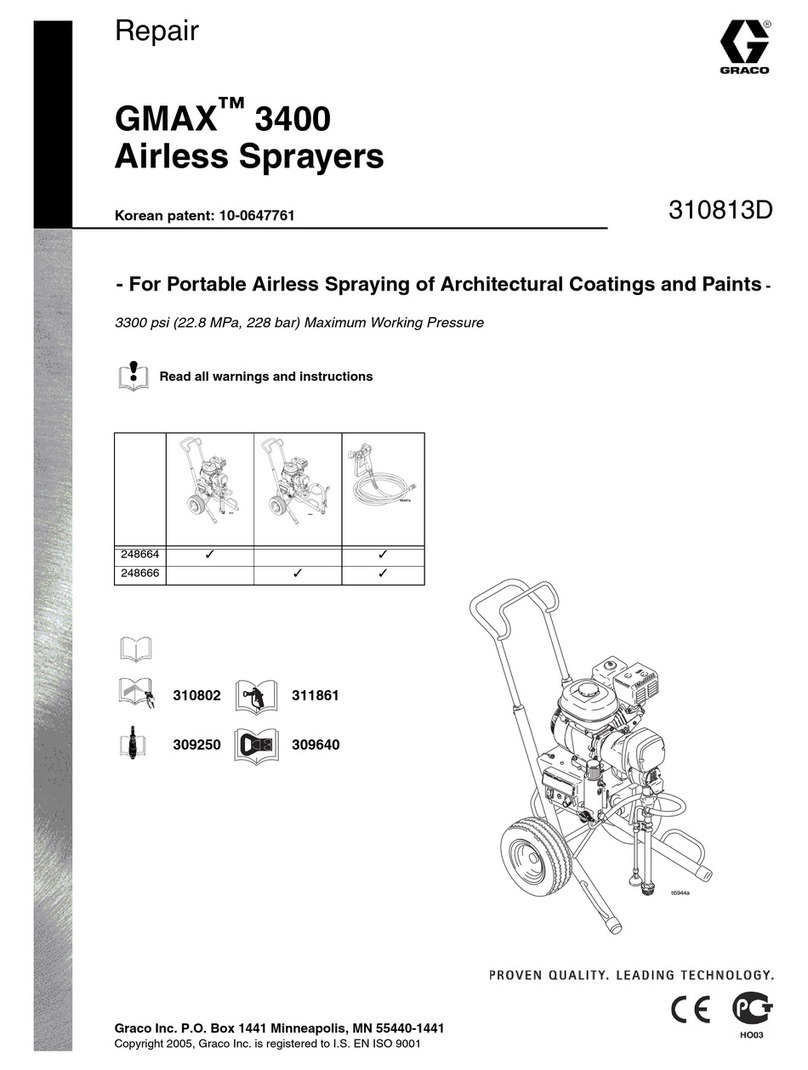

Graco 310813D Operating instructions

Graco

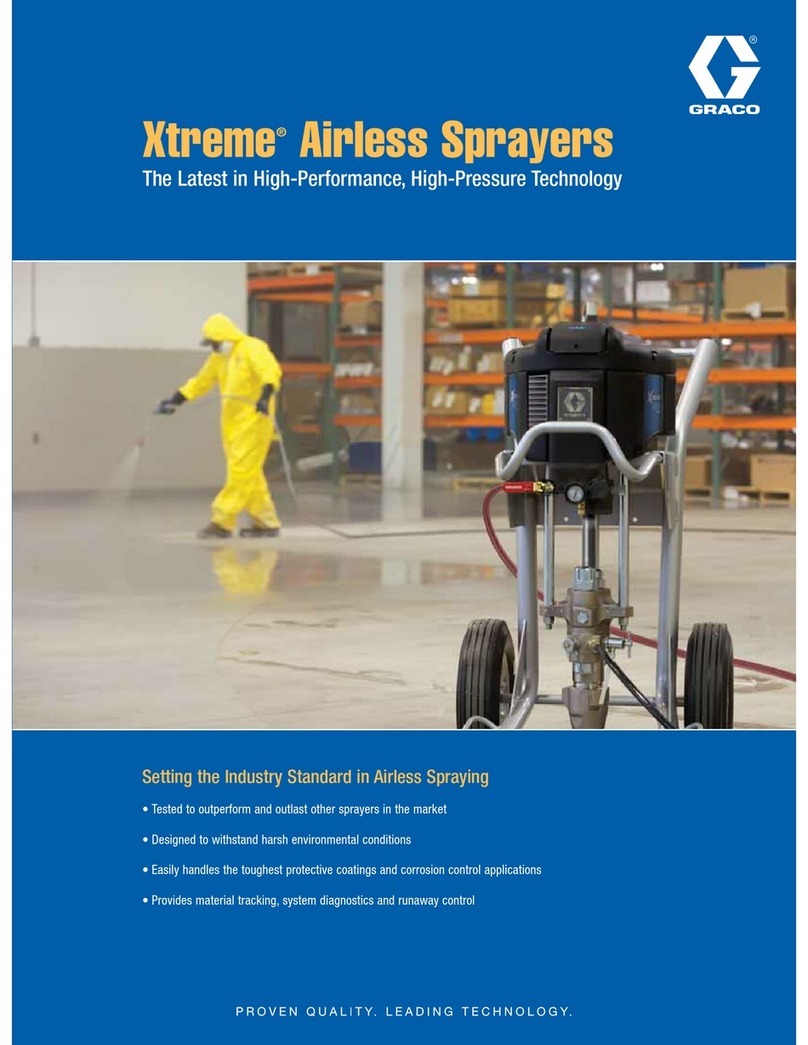

Graco Xtreme NXT User manual

Graco

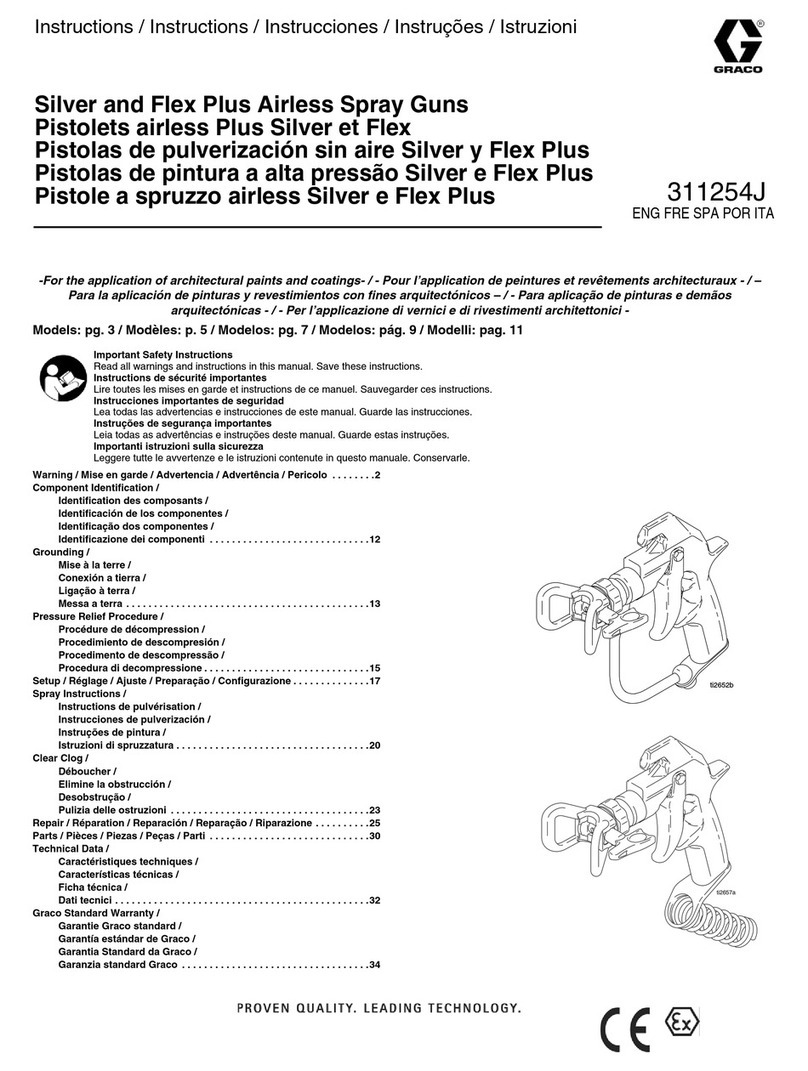

Graco ti2652b User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual