page 7

Living With a Watermaker

Now that you own a watermaker, what do you do with it? Making good drinkable water

for sure, but there is more to it. You may not think it now but your watermaker will probably

become a “mission critical” component for you. Like your engine, sails, and safety gear you

will not want to go to sea without it. The following is to help you better understand the process

of water making and making water reliably.

Theory of Reverse Osmosis

“Semi Permeable Membrane” You may remember that term from some science class.

Each cell in our bodies is covered with one. It’s designed to be able to exchange desired

chemicals in and out but reject unwanted ones. “Osmosis” (another science class term) is a

phenomenon where a solution with a high concentration of “something” (lets say salt water)

and a solution with a low concentration of the same dissolved “something” (fresh water) happen

to be separated by a semi permeable membrane, a very strange thing happens. The fresh water

wants to force itself through the membrane to dilute the salt water and the salt wants to migrate

to fresh water side. “Osmotic pressure” is created by the fresh water forcing itself into the salt

water side where there isn’t enough room for it. With sea water, osmotic pressure can build up

to almost 400 pounds per square inch (psi). “Reverse Osmosis” (RO) happens when an

artificial pressure, higher that the osmotic pressure, is applied to the sea water side. This will

force fresh water back through the membrane. A little salt does go through but is highly diluted

by the fresh water. There is a rub however. On the sea water side, as the fresh water passes

through the membrane, the salts molecules crowd up against the membrane surface which starts

to block the flow of fresh water. To stop this, a constant flow of new sea water must flow along

the membrane surface to wash away the concentrating salts. So to have reverse osmosis we

must have sea water flowing, at a pressure much higher than 400 psi, along the membrane

surface. The spiral wound “thin film composite” membrane “element” that is in your pressure

vessel was developed for this.

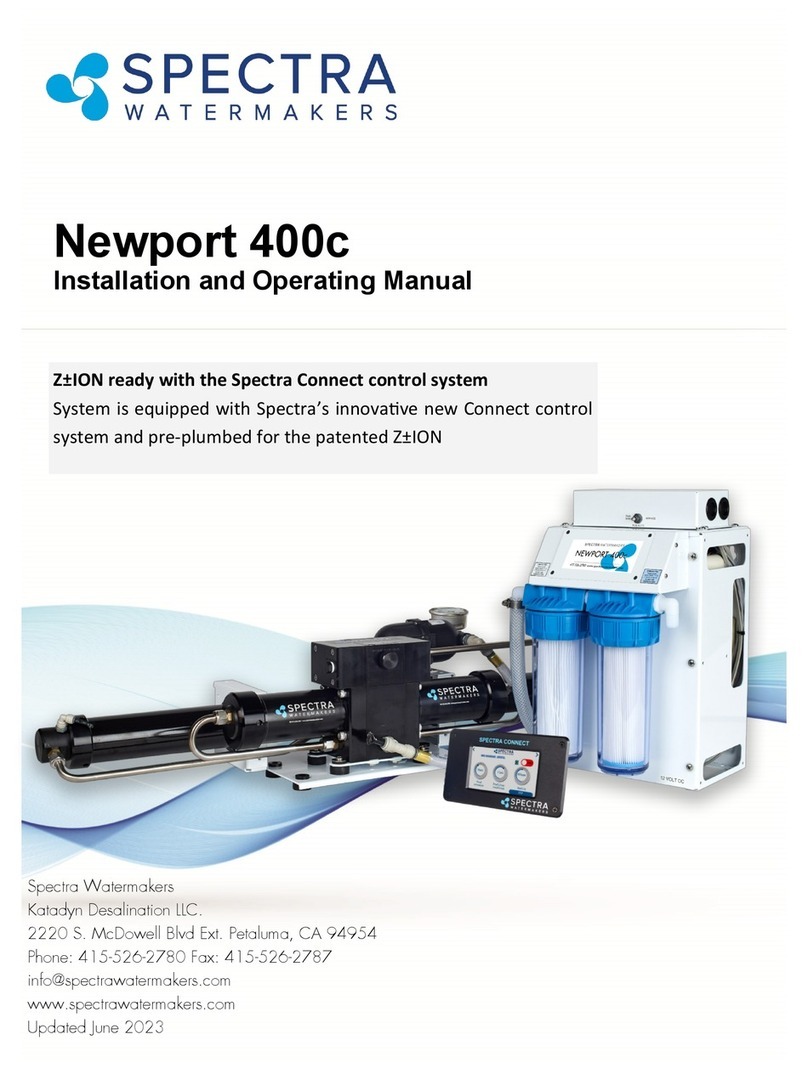

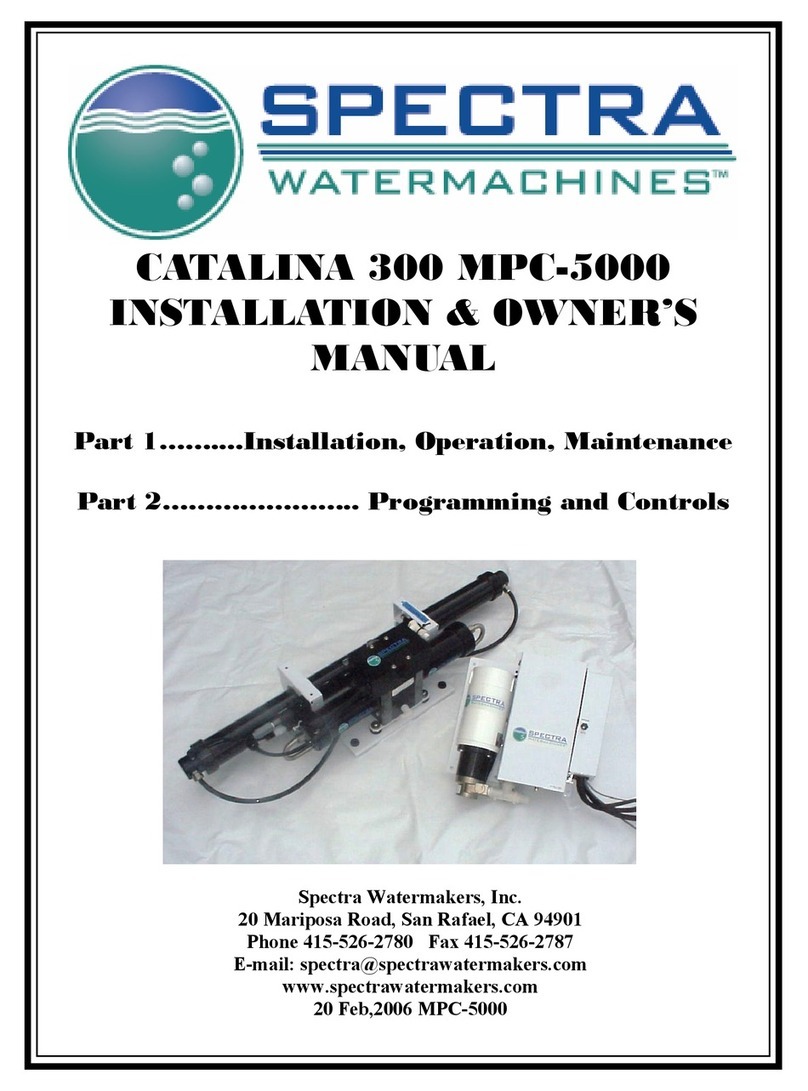

The Modern Marine Reverse Osmosis Watermaker

A water maker system must deliver a filtered high pressure flow of seawater through the

membrane. That’s it. Some may have more bells and whistles than others but they all generate

the high pressure flow. The trick is to do it efficiently, quietly, and reliably. Your Spectra

system, with its 21st century Clark Pump technology, does it all.

There are several things that can hamper a system, most caused by poor installation,

and/or operator error and neglect. With the system set up properly, there has to be an

unrestricted supply of seawater without air bubbles to the inlet of the system, the sea water must

be filtered to 5 microns, the power wiring must be the right size with good connections, the

system should be flushed with fresh water after use, if the system isn’t going to be used for a

while it has to be properly stored or “pickled” to stop bio-fouling and/or freezing which will

damage the membrane, and all service points placed in a convenient position.

Installing Your Watermaker

The installer must read the manual even if he or she has installed other Spectra systems.

New information is constantly being added to our documentation. A lot comes from customer

input. Pay special attention to the intake instructions, they must be followed. Even if you are

not installing the watermaker yourself, read through the whole introduction and operation

sections of the manual before starting. This will help you plan the layout of your watermaker.→