308-722 5

Operation

Lubricator Operation

The

lubricator meters oil into the moving air stream to

automatically lubricate air-operated motors. A manual

adjustment in the housing sets the oil drip rate into the

air stream, which can be monitored through a sight

glass. One to two drops of oil per minute is common.

Use an oil rated at 50 to 200 SUS (ISO grade 7 to 46)

at 100

F (38

C), such as Graco motor oil, Part No.

202–659.

WARNING

T

o reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

on page 4.

T

o refill, unscrew the fill plug (F

, page 8) and pour in

the oil. The lubricator

’

s capacity is 7 oz (0.2 liter).

Check the oil level with the sight glass. The lubricator

can be refilled with the system pressurized. However

,

always

relieve the system pressure

before removing

the bowl for any reason.

Service

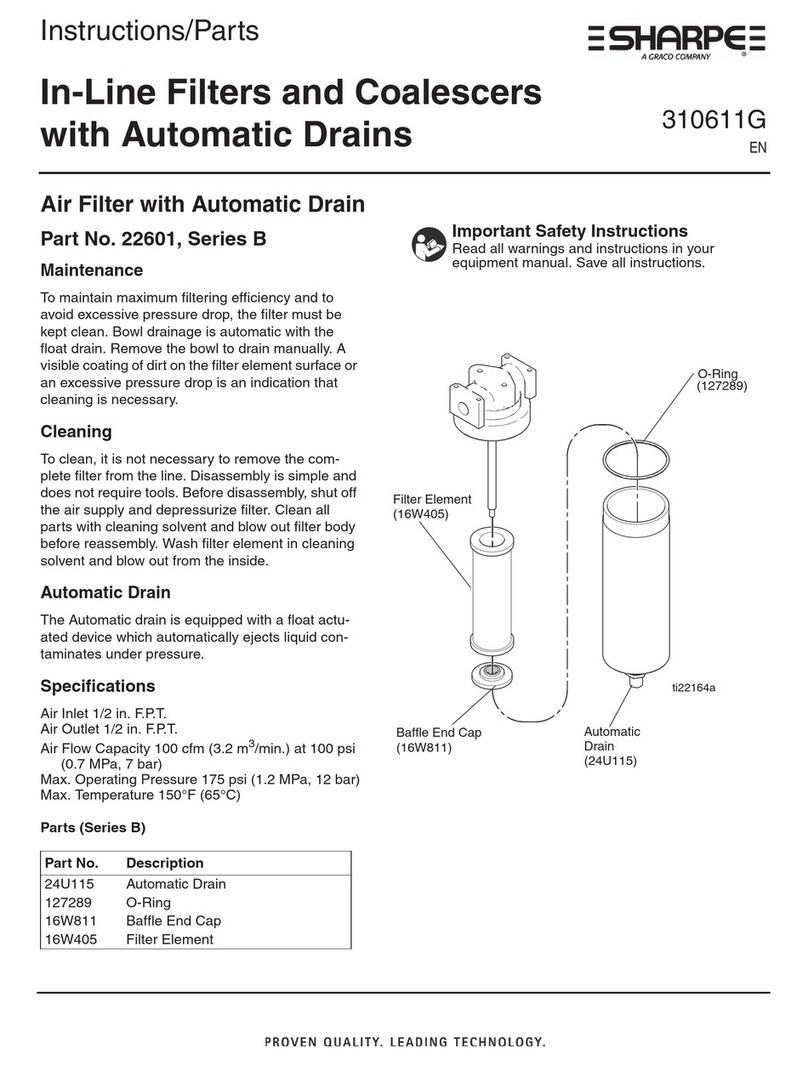

Air Filter Service

Repair

Kits are available. Refer to page 6.

Every day

, drain contaminants from the bowl before

reaching the baf

fle level by opening the drain (D) at the

bottom of the bowl (B).

WARNING

T

o reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

on page 4.

Clean the air filter regularly to maximize filtering ef

fi-

ciency and to avoid excessive pressure drop. Fully

relieve pressure

to remove the bowl (B).

Clean the filter element (1

1

1) and bowl using house

-

hold soap and water or denatured alcohol. Use com

-

pressed air to blow out the filter body

. Blow the filter

element out from the inside.

Clean the sight glass (109) thoroughly

. Do not leave

solvent residue in the sight glass as it may attack or

weaken the glass. If the sight glass appears damaged,

replace it immediately

.

Regulator Service

Repair

Kits are available. Refer to pages 6 and 7.

If the regulator fails to operate, operates roughly

, or

vibrates, service it as follows.

WARNING

T

o reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

on page 4.

Fully

relieve pressure

and remove the regulator from

the air line.

Refer to pages 6 and 7. Disassemble the regulator

.

If it is a filter/regulator

, clean the filter bowl and ele

-

ment as described under

Air Filter Service.

Clean the parts with household soap and water or

denatured alcohol. Wipe dry with a clean, soft cloth.

Use compressed air to blow dirt and contaminants out

of the regulator body

.

Inspect all parts for wear or damage. Replace dam

-

aged parts.

Lubricate the bearing area, all o-rings, adjusting screw

threads, and spring ends with no. 2 lithium-base

grease. Reassemble the regulator

.