Graco 24R253 User manual

Other Graco Water Pump manuals

Graco

Graco VRM User manual

Graco

Graco Series B Operation manual

Graco

Graco Hydra-Cat H.P. Series User manual

Graco

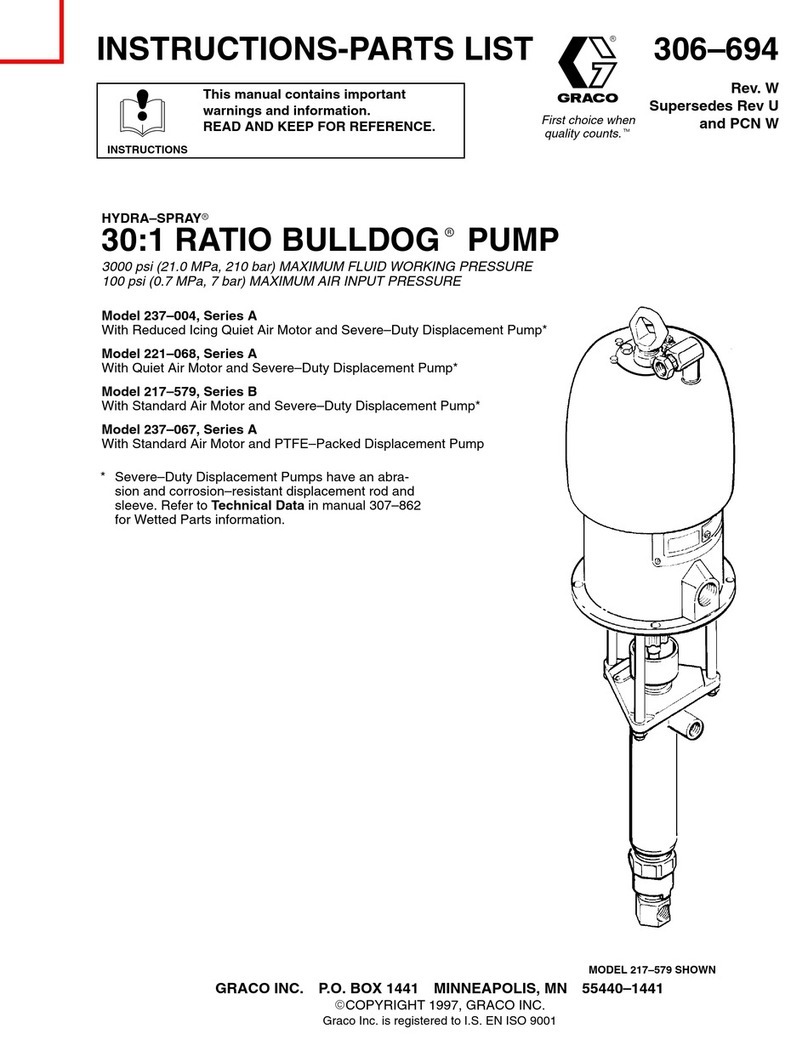

Graco 237-004 Operation manual

Graco

Graco President A Series Operation manual

Graco

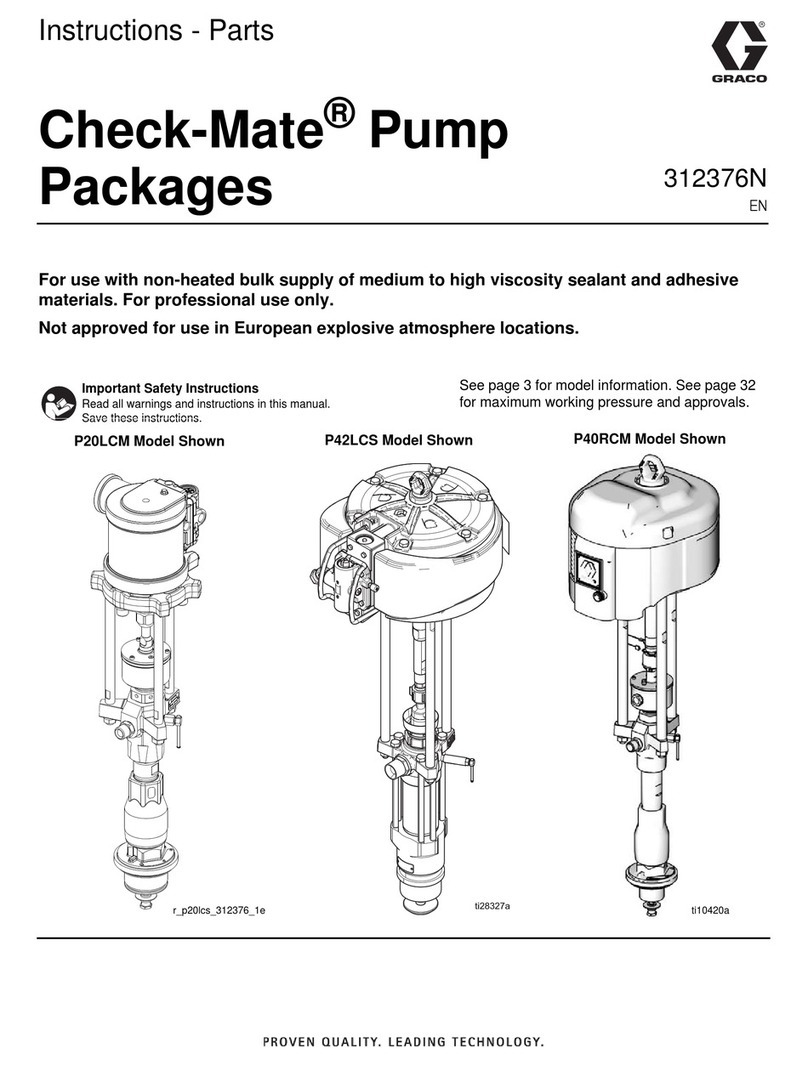

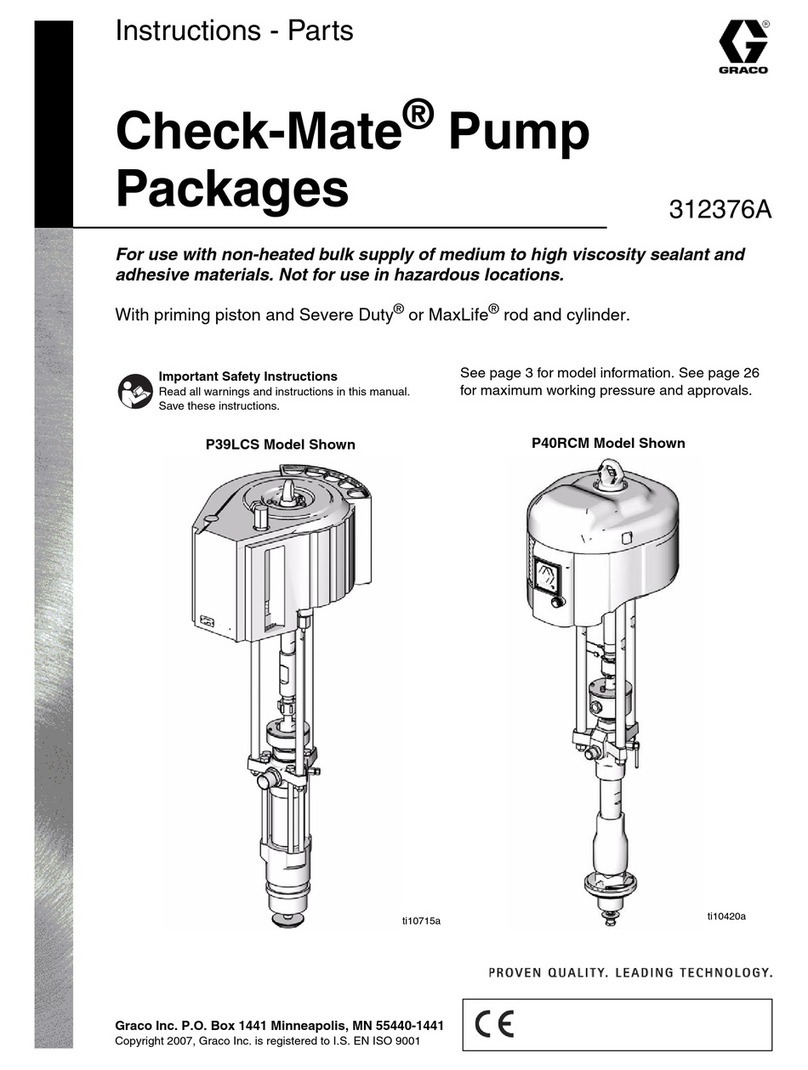

Graco Check-Mate P20LCM User manual

Graco

Graco ChemSafe 307 Parts list manual

Graco

Graco ChemSafe 205 Operation manual

Graco

Graco 25P031 User manual

Graco

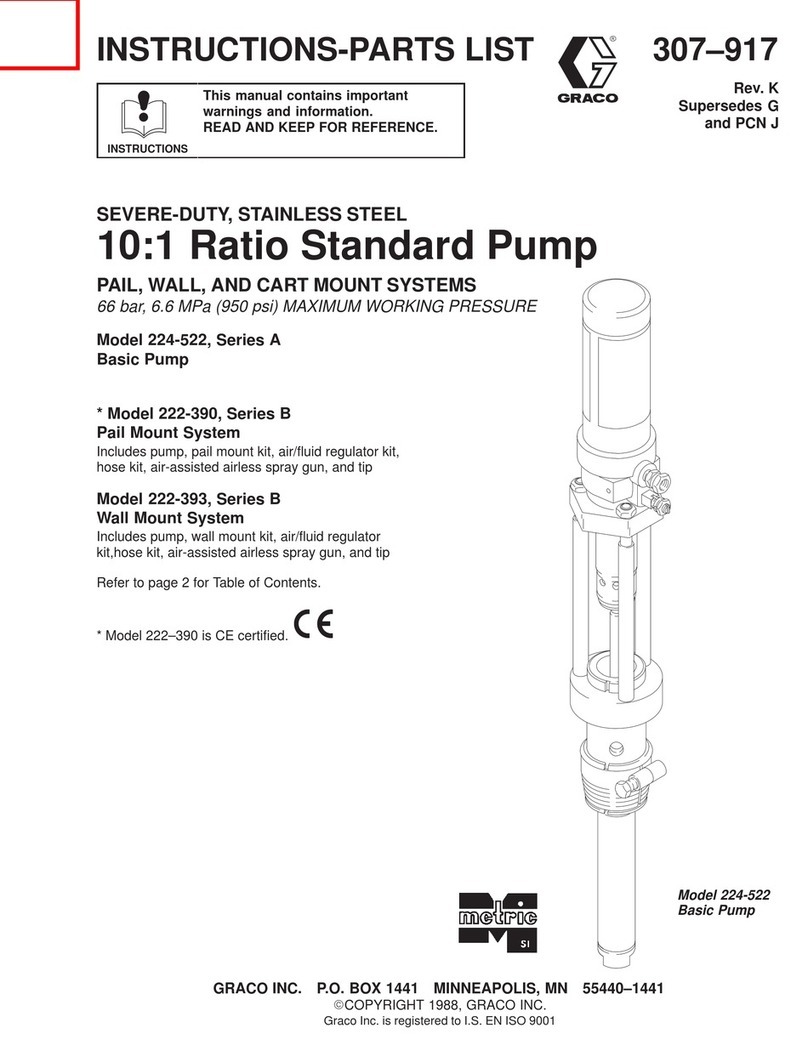

Graco Series A Operation manual

Graco

Graco SaniForce FW1111 User manual

Graco

Graco Check-Mate P40LCS User manual

Graco

Graco Fire-Ball 425 E Series Operation manual

Graco

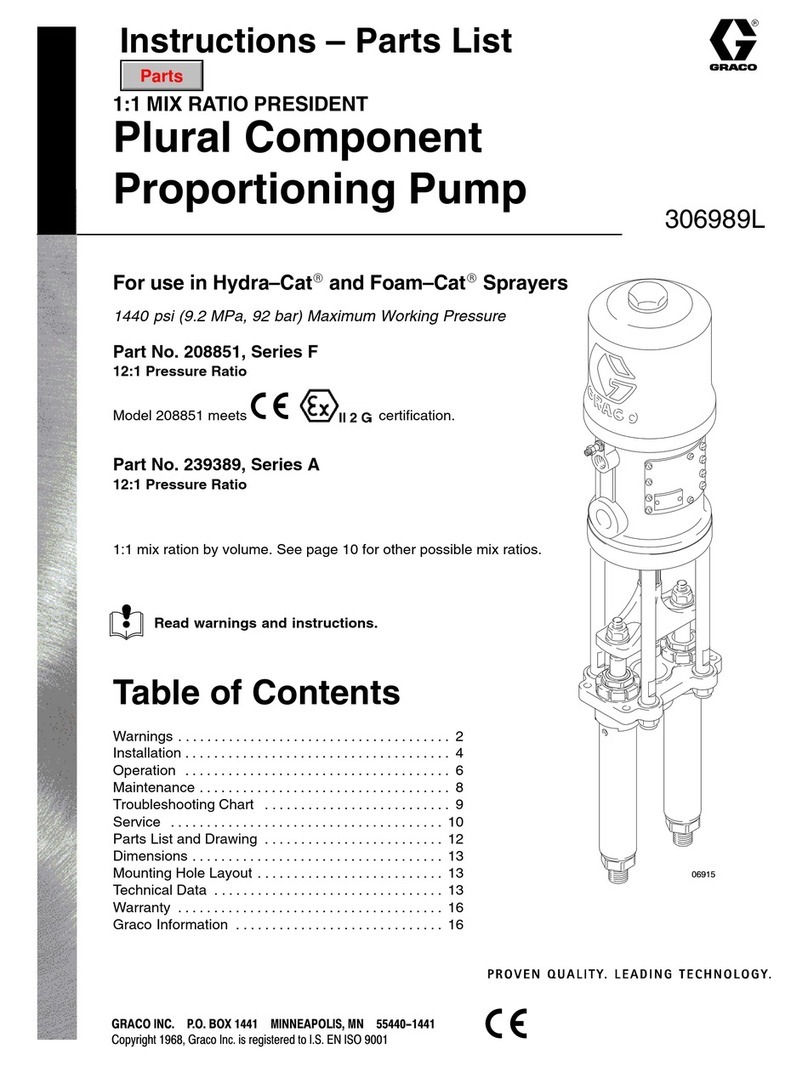

Graco SERIES F Operation manual

Graco

Graco SaniForce 2150e Instruction Manual

Graco

Graco Husky 1050 Series Instruction Manual

Graco

Graco Husky 2200 Use and care manual

Graco

Graco Series A Parts list manual

Graco

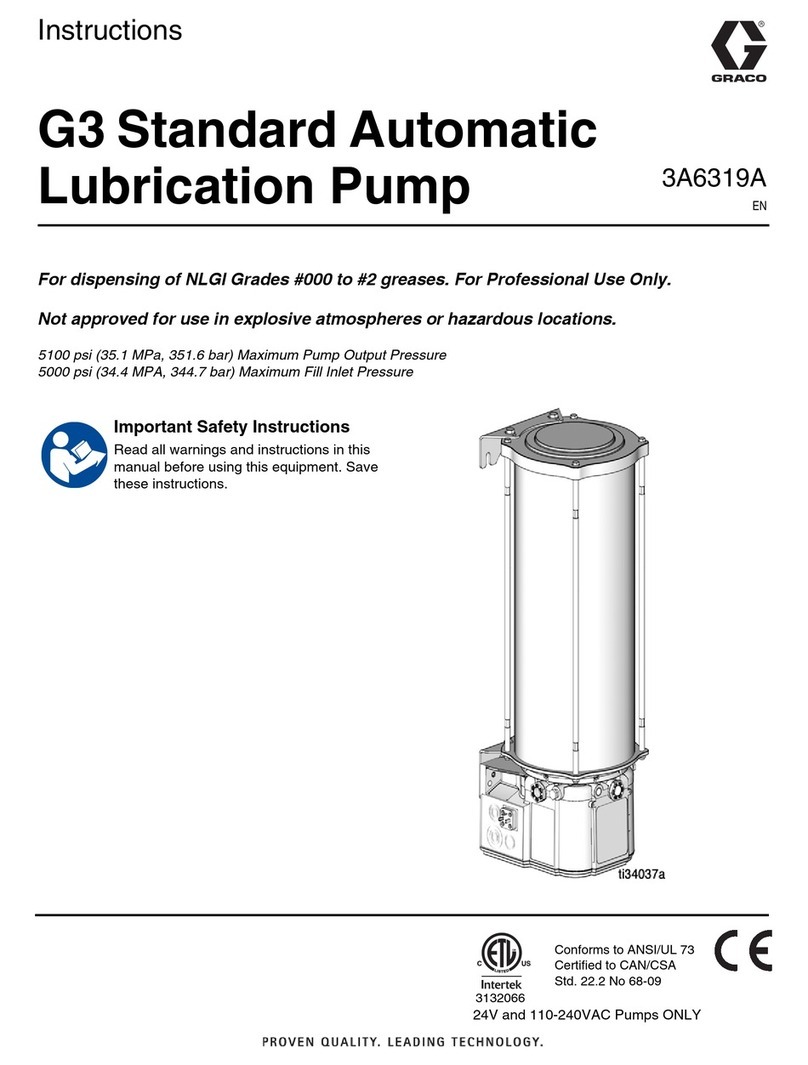

Graco G3 Series User manual

Graco

Graco Husky 1050e Use and care manual

Popular Water Pump manuals by other brands

Fieldmann

Fieldmann FVC 5015 EK user manual

Everbilt

Everbilt EFSUB5-122HD Use and care guide

esotec

esotec 101018 operating manual

Becker

Becker BASIC VASF 2.80/1-0.AC230 operating instructions

Sykes AmeriPumps

Sykes AmeriPumps GP100M Operation and maintenance instructions

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual

GÜDE

GÜDE HWW 900 GC Translation of the original instructions