Contents

Related Manuals ................................................ 2

Warnings ........................................................... 3

onfiguration Number Matrix............................... 6

Ordering Information........................................... 8

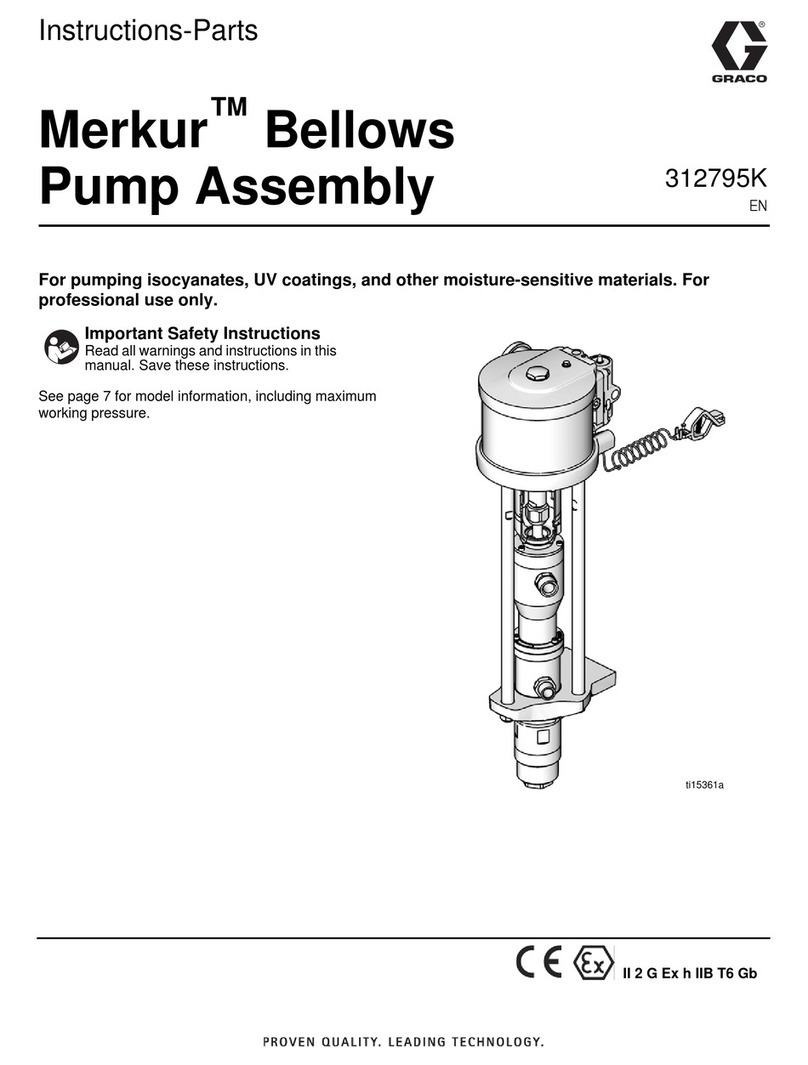

Overview............................................................ 9

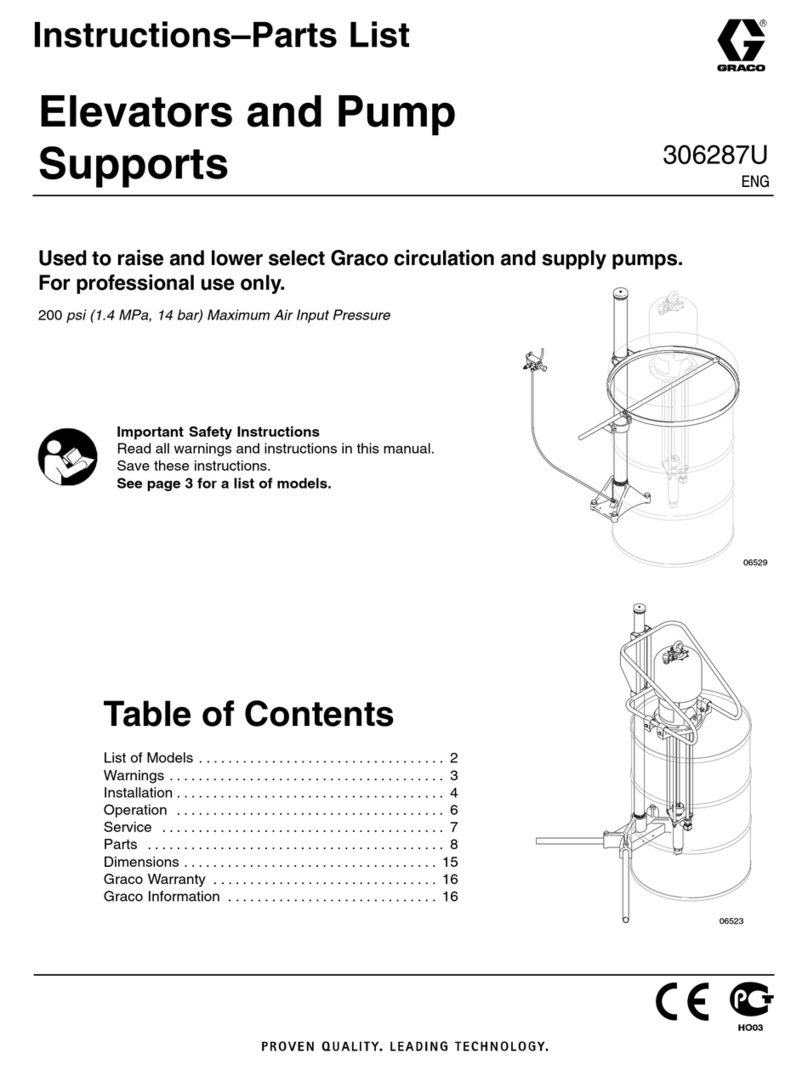

Installation.......................................................... 10

General Information ..................................... 10

Tighten Fasteners........................................ 10

Tips to Reduce avitation............................. 10

Mount the Pump ..........................................13

Grounding ................................................... 14

Air Line........................................................ 15

Fluid Supply Line ......................................... 15

Fluid Outlet Line........................................... 15

Leak Sensor ................................................ 16

Electrical onnections (A Models)..................... 17

Wire onnections at the Variable

Frequency Drive (VFD) ................... 17

Wire onnections at the Standard

Motor............................................. 17

Wire onnections at the ATEX Motor............ 18

Wire onnections at the Explosionproof

Motor............................................. 18

Leak Sensor Wiring (A Models) .................. 19

Electrical onnections (BLD Models)................. 20

onnect ables ........................................... 20

Wiring Tips .................................................. 21

BLD Motor Wiring ...................................... 22

ontroller Wiring.......................................... 23

Leak Sensor Wiring (BLD Models).............. 24

PL Wiring.................................................. 24

ompressor Wiring............................................. 25

art Wiring......................................................... 26

Operation........................................................... 27

Tighten Fasteners........................................ 27

Initial onfiguration (A with VFD)................ 27

Initial onfiguration (BLD with Graco

Motor ontrol) ................................ 27

Flush the Pump Before First Use .................. 27

Transfer Mode Vs. Low Pulsation

Mode ............................................. 27

Start and Adjust the Pump............................ 28

Flow alibration Procedure........................... 28

Batch alibration Procedure ......................... 29

Pressure Relief Procedure............................ 29

Pump Shutdown .......................................... 29

Graco Motor ontrol Operation (BLD

Models) ................................................ 30

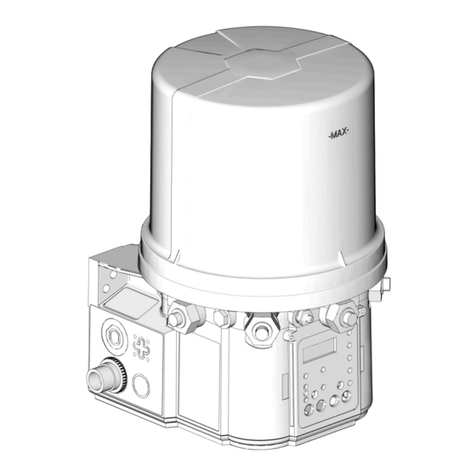

Display........................................................ 30

Graco Motor ontrol Software

Overview........................................ 31

Operation Modes ......................................... 34

Maintenance ...................................................... 41

Maintenance Schedule................................. 41

Tighten Threaded onnections..................... 41

lean the Graco Motor ontrol ..................... 41

Upgrade Graco Motor ontrol

Software ........................................ 41

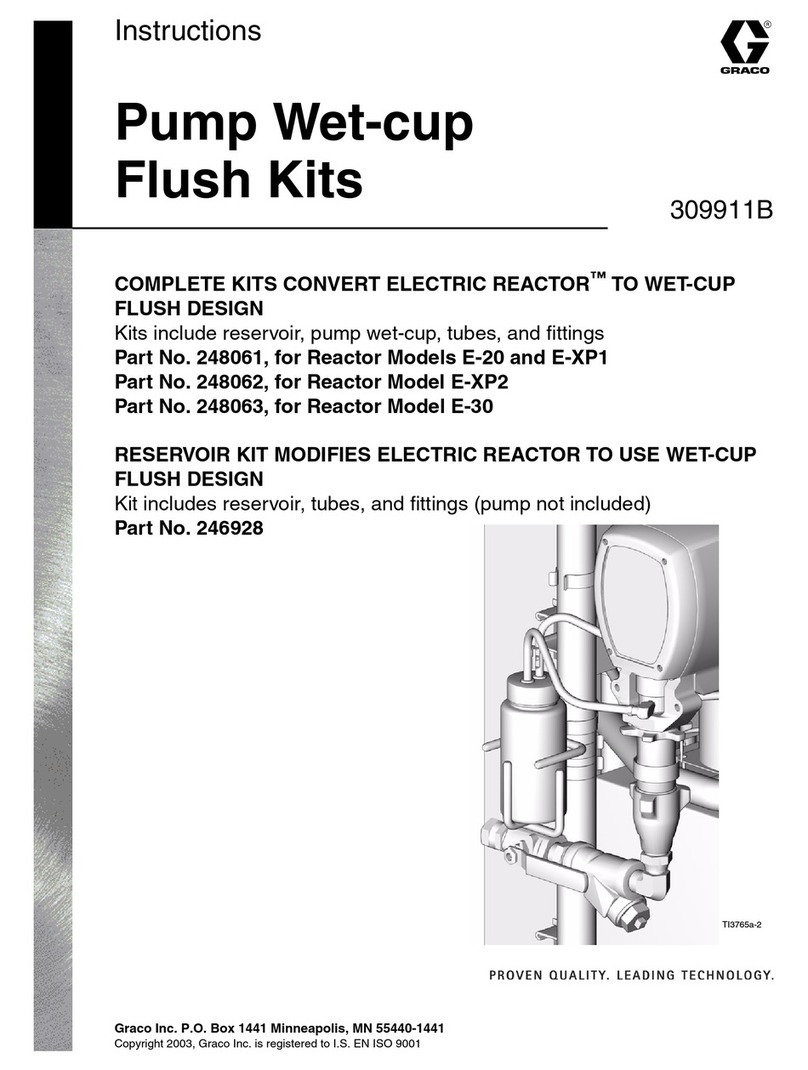

Flushing and Storage ................................... 42

Troubleshooting the Graco Motor ontrol............. 43

Diagnostic Information.................................. 44

Power Line Voltage Surges ..........................45

Test Power Line with Multimeter ................... 45

Events......................................................... 46

Torque Instructions............................................. 49

Performance harts............................................ 50

Dimensions........................................................ 56

Technical Data ................................................... 66

Graco Standard Warranty.................................... 72

Related anuals

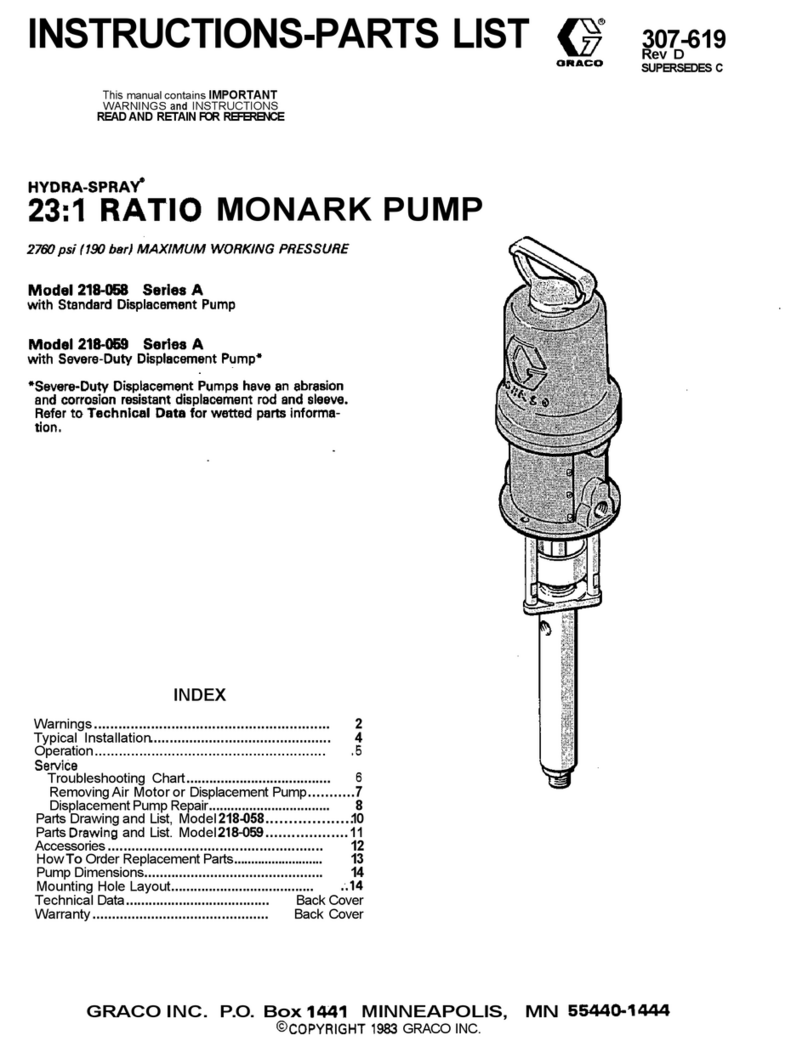

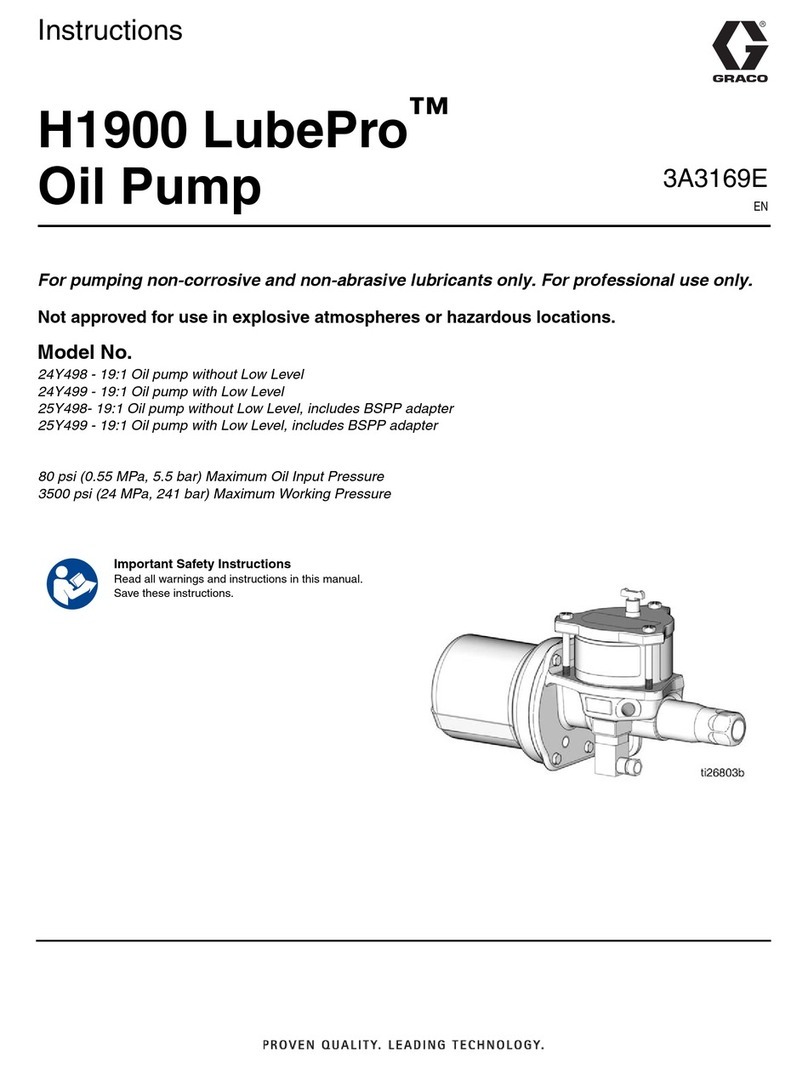

Manual Number Title

334189 Husky 1050E Electric Double Diaphragm Pump, Repair/Parts

334188P