FIRE

OR

EXPLOSION

HAZARD

through the pump and hose. If every part of thespray equip-

Static electricity is created by the high velocity flow

of

fluid

rnent is not properly grounded, sparking may occur, and the

systemmay become hazardous. Sparking mayalso occur

when plugging in or unplugging

a

power supply cord.Sparks

can ignite fumes from solvents and the fluid being sprayed,

dust particles and other flammable substances. whether you

are spraying indoors or outdoors, and can cause

a

fire or ex-

plosionand seriousbodily injury and propertydamage. Do not

plug

in

or unplug any power supply cords in the spray area

when there is any chance of ignitingfumes still in the

air.

If you experienceany static sparking or evena slight shock

whileusingthis equipment,STOPSPRAYING IMMEDIATE-

thesystem again untiltheproblem hasbeen identified and

LY. Check the entire system forproper grounding. Do notuse

corrected.

Grounding

To reducethe risk of staticsparking, ground the pump andall

other spray equipment usedor located inthe spray area.

CHECK yourlocalelectrical code fordetailedgrounding in-

structions for your area and type of equipment. BE SURE to

ground

all

of

this

spray equipment:

1.

Pump:

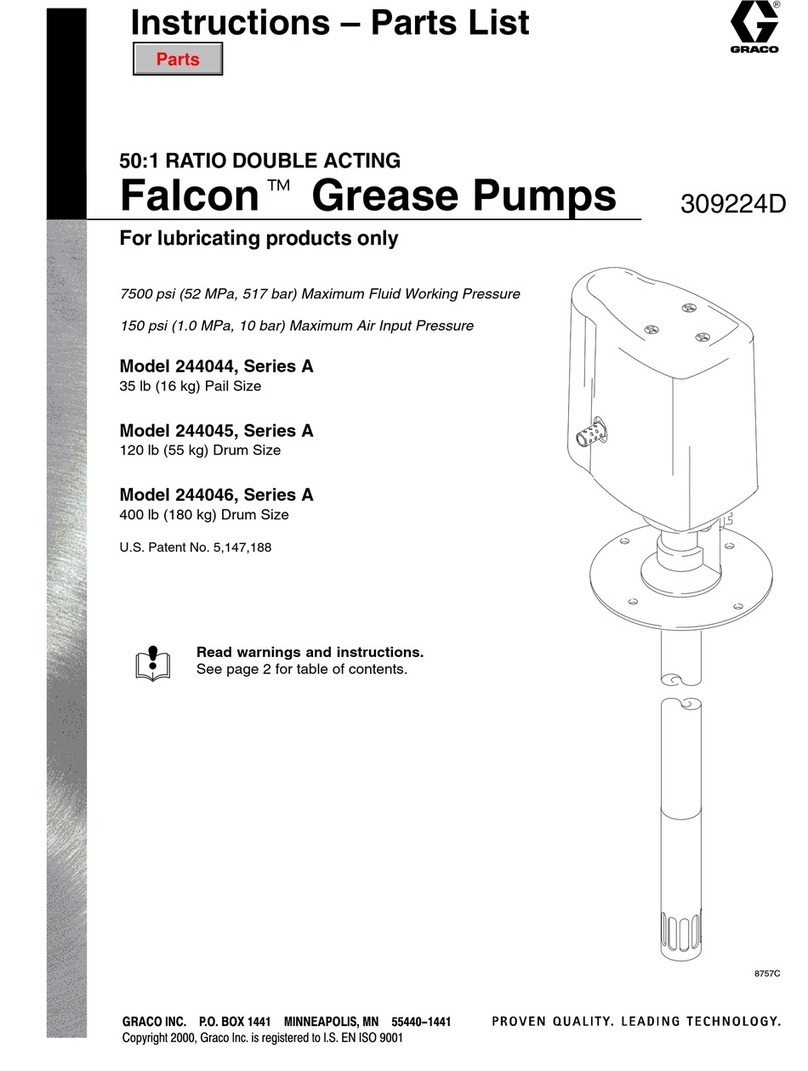

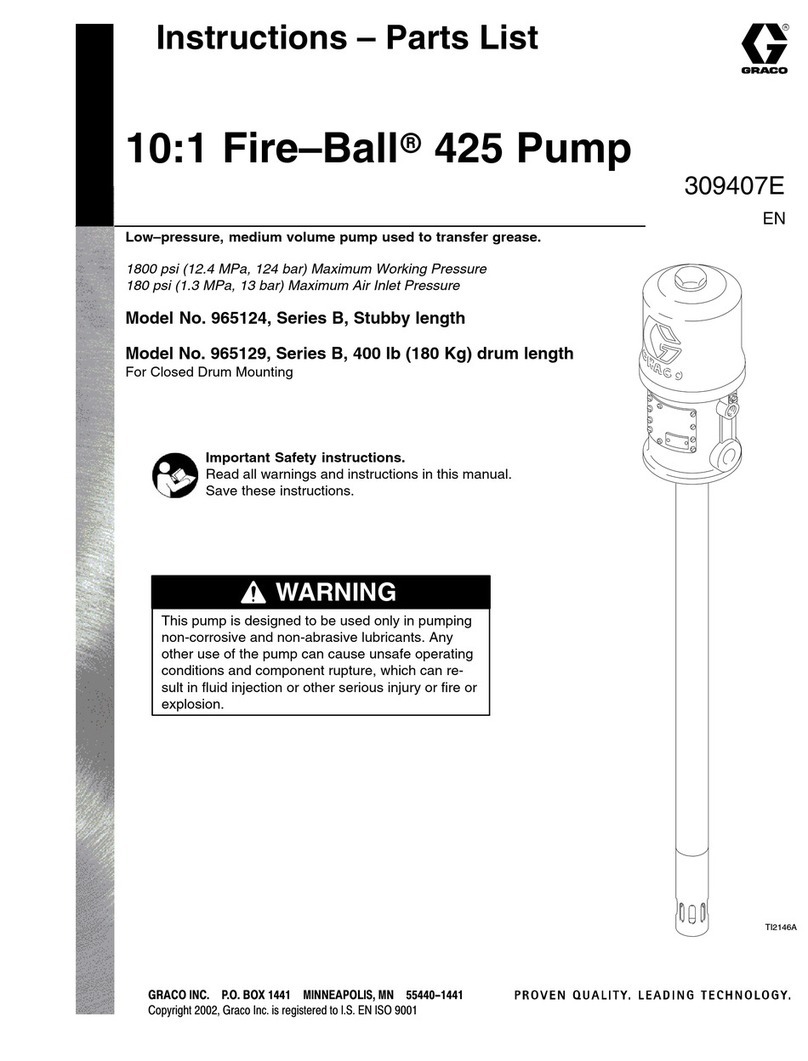

use a ground wire and clamp as shown in Fig

1.

2.

Air hoses:use only grounded air hoses.

3.

Fluid

hoses:use only grounded fluid hoses.

4.

Air compressor: follow manufacturer'srecommendations.

5.

Spray

gun

or

dispensing velve: grounding is obtained

through connection to

a

properly grounded fluidhose and

pump.

6.

Fluid

supply container: accordingto local code.

7.

Object beingsprayed: according to your

lo&l

code.

8.

All solventpails used whenflushing,according to local

code. Use only metalpails, which are conductive, placed

on

a

grounded surface.

Do

notplace the pail on a non-

terrupts the grounding continuity.

conductive surface, such as paper or cardboard, which in-

9.

To

maintain grounding continuity when flushing or reliev-

ing

pressure, alwayshold a metalpart ofthegunlvalve

firmly to the side of a groundedmetalpail, then trigger the

gunlvalve.

Fig

1

Togroundthepump,lwsenthegroundingluglocknut~andwasher

the

slot

inlug

(2)

and tighten locknutsecurely.See Fig.

1.

Mnnecttb

(X).

lnselt one end

of

a

12

ga.

(1.5

mmz) minimum groundwire

M

into

otherendofthewiretoatruee~ground.Refertopage18ioordera

ground wire and clamp.

Flushing

Safety

Toreduce the risk of injection injury, static sparking, or

splashing follow the Pressure Relief Procedureon page

2,

and remove the spray

tip

(spray guns or spray valves only)

before flushing. Hold a metal part of the gunlvalve firmly

to

the side of a grounded metalpail and use the lowest possible

fluid pressure during flushing.

MOVING PARTS HAZARD

The piston

in

the air motor,locatedbehindthe air motor

plates, moveswhen air

is

suppliedtothe motor. Movingpa-

can pinchoramputateyourfingers or otherbodyparts.

Therefore, NEVER operate the pumpwith theair motor plates

removed. KEEPCLEAR of movingpartswhenstartingor

operating the pump. Before checking or servicing the pump,

follow the Pressure

Relief

Procedure onpage

2

to

prevent

the pump from starting accidentally.

HOSE

SAFETY

High pressure

fluid

in

the

hoses

can

be

verydangerous.

If

the HANDLEAND ROUTE

HOSES

CAREFULLY. Donotpullon

hose develops

a

leak, split or rupture due

to

any kind of wear,hoses to move equipment.

Do

not usefluids or solvents which

damageormisuse, the highpressuresprayemittedfrom

it

canare notcompatiblewith the inner tube andcover of the hose.

cause a fluid iniection iniurv or other serious bodilv iniurv or

property damage.

,.

I

,~

,

ALLFLUIDSPRAY HOSES MUSTHAVE SPRING

GUARDS

ON

BOTH ENDS1The spring guardshelp protect

the

hosa

fromkinks or bends at orcl&e toihecoupling which

can result in hose rupture.

TIGHTENa11 fluid connectionssecurely beforeeach use. High

pressure fluid can dislodge

a

loose coupling or allowhigh

pressure spray

to

be emitted from the coupling,

hose for cuts,leaks,abrasion, bulging cover, or damageor

NEVER useadamagedhose.Beforeeach use, check entire

exist, replace the hose immediately. DO NOT

try

to recouple

movement of the hose couplings.

If

any of these conditions

high pressure hoseor mend

it

withtape or any otherdevice. A

repaired hosecannot contain the

high

pressure

fluid.

Hose

Grounding

Continuity

Proper hosegrounding continuityis essentialto maintaininga

air and fluidhosesat least oncea week. If yourhose doesnot

groundedspray system. Checkthe electricalresistanceof your

havea tagon

it

which specifies themaximumelectrical

resistance, contact the hose supplier or manufacturerfor the

maximum resistance limits. Use a resistance meter in theap-

propriate range for your hose to check the resistance. If the

resistanceexceeds the recommended limits, replace

it

im-

mediately.An ungrounded or poorly groundedhosecanmake

yoursystem hazardous.Also,read

FIRE

OR

EXPLOSION

HAZARD, above.

IMPORTANT

ticulariy the General Standards, Part 1910, and the Construction Standards, Part 1926-should be consulted.

United States Government safetystandards have beenadopted under the Occupational Safetyand Health Act.Thesestandards-par.

306-726

3