EQUIPMENT MISUSE HAZARD

General

Safety

Any

misuse of the spray/dispensing equipment or accesso

-

ries, such as overpressurizing, modifying parts, using incom

-

patible chemicals and fluids, or using worn or damaged parts,

can cause them to rupture and result in fluid injection, splash

-

ing in the eyes or on the skin, or other serious bodily injury

, or

fire, explosion or property damage.

Never alter or modify any part of this equipment; doing so

could cause it to malfunction.

Check all spray/dispensing equipment regularly and repair or

replace worn or damaged parts immediately

.

Always wear protective eyewear

, gloves, clothing and respi

-

rator as recommended by the fluid and solvent manufacturer

.

System

Pressure

The

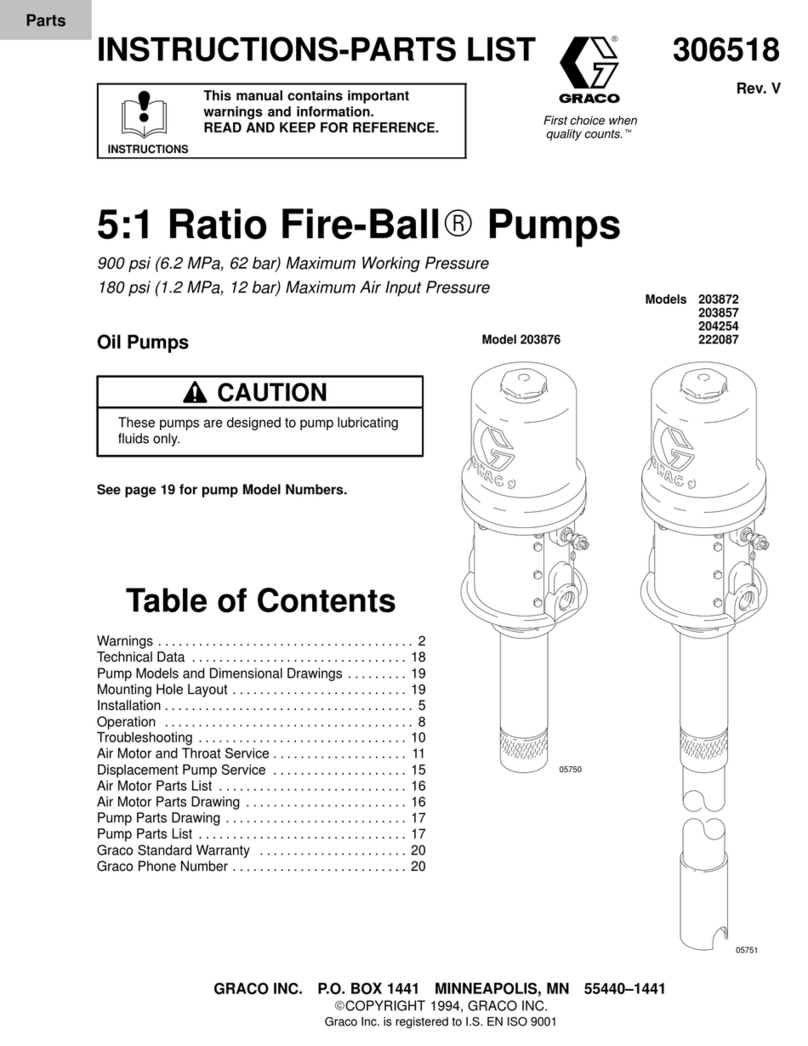

maximum safe working pressure is determined by the air

or hydraulic motor. Do not exceed the maximum working

pressure stated on your complete pump.

Be sure that all spray equipment

and accessories are rated to

withstand the maximum working pressure of the pump. Do

not exceed the maximum working pressure of any compo

-

nent or accessory used in the system.

Fluid

Compatibility

Be

sure that all fluids and solvents used are chemically com

-

patible with the wetted parts shown in the

T

echnical Data

on

the back cover

. Always read the manufacturer

’

s literature

before using fluid or solvent in this pump.

FIRE

OR EXPLOSION

HAZARD

Static

electricity is created by the high velocity flow of fluid

through the pump and hose. If every part of the spray/dis

-

pensing equipment is not properly grounded, sparking may

occur

, and the system may become hazardous. Sparking

may also occur when plugging in or unplugging a power sup

-

ply cord. Sparks can ignite fumes from solvents and the fluid

being sprayed/dispensed, dust particles and other flammable

substances, whether you are spraying/dispensing indoors or

outdoors, and can cause a fire or explosion and serious bod

-

ily injury and property damage. Do not plug in or unplug any

power supply cords in the spray/dispensing area when there

is any chance of igniting fumes still in the air

.

If you experience any static sparking or even a slight shock

while using this equipment,

stop spraying/dispensing im

-

mediately.

Check the entire system for proper grounding. Do

not use the system again until the problem has been identi

-

fied and corrected.

Grounding

T

o reduce the risk of static sparking, ground the pump and all

other spray/dispensing equipment used or located in the

spray/dispensing area. Check your local electrical code for

detailed grounding instructions for your area and type of

equipment. Be sure to ground all of this spray/dispensing

equipment:

1.

Pump:

Ground the complete pump as indicated in your

separate pump instruction manual.

2.

Air or hydraulic hoses:

use only grounded hoses.

3.

Fluid hoses:

use only grounded fluid hoses.

4.

Air compressor or hydraulic supply:

follow manufactur

-

er’

s recommendations.

5.

Spray gun/dispensing valve:

grounding is obtained

through connection to a properly grounded fluid hose

and pump.

6.

Fluid supply container:

according to your local code.

7.

Object being sprayed:

according to your local code.

8.

All solvent pails used when flushing,

according to your

local code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the pail on a

nonconductive surface, such as paper or cardboard,

which interrupts the grounding continuity

.

9.

T

o maintain grounding continuity when flushing or reliev

-

ing pressure

, always hold a metal part of the spray gun/

dispensing valve firmly to the side of a grounded

metal

pail, then trigger the spray gun/dispensing valve.

Flushing

Safety

Before

flushing, be sure the entire system and flushing pails

are properly grounded. Refer to

Grounding

, at the left.

Follow the

Pressure Relief Procedure

on page 2, and

remove the spray tip/nozzle from the spray gun/dispensing

valve. Always use the lowest possible fluid pressure, and

maintain firm metal-to-metal contact between the spray

gun/dispensing valve and the pail during flushing to reduce

the risk of fluid injection injury

, static sparking and splashing.

MOVING

P

ARTS HAZARD

Moving

parts can pinch or amputate your fingers or other

body parts. In air-powered systems, the air motor piston (lo

-

cated behind the air motor shield) moves when air is supplied

to the motor

. Therefore, never operate the pump with the air

motor

shield removed. Keep clear of moving

parts when start

-

ing

or operating the pump. Before checking or servicing the

pump, follow the

Pressure Relief Procedure

on page 2 to

prevent the pump from starting accidentally

.