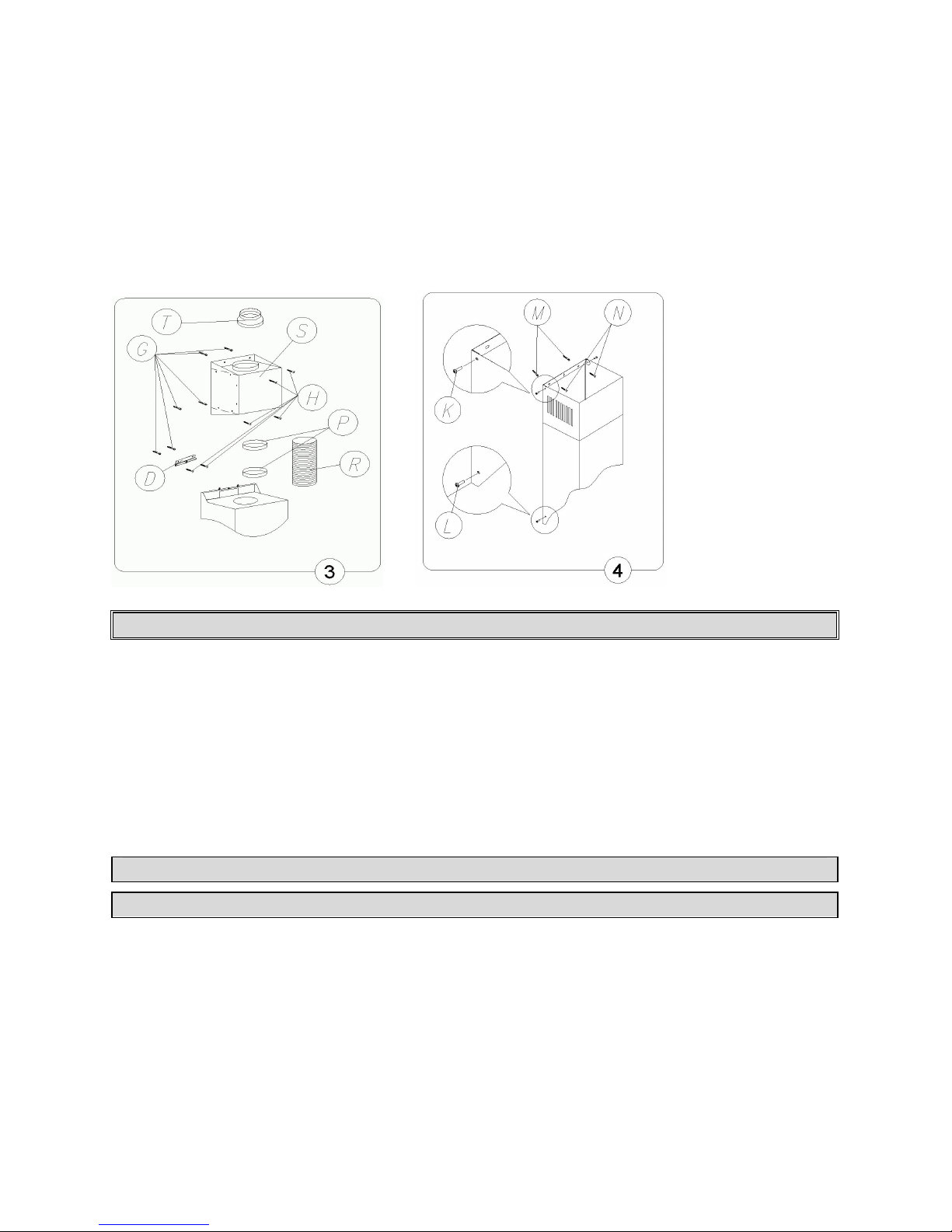

- The lighting pushbutton "L" is used to switch on and off the extraction hood lighting;

independently of the motor work status, push this pushbutton to switch on/off the

lighting; holding it pushed down for about 2 seconds causes the lighting switchover

from the maximum level to the nearest lower level.

2.2. Program function

ODOUR SENSOR:

The automatic system operation is activated before the beginning of cooking and after

5 minutes of the moment of the first connection of the plug to the 230 V ~ power

network (calibration of the air sensor for the surrounding conditions). The switching-on

the automatic operation mode puts the process of air examining by means of the odour

sensor into operation. The appearance of a pollution on a determined level has the

switching-on of the extraction hood with the speed adequate to this pollution level as

the consequence. The reduction of the pollution level causes a gradual reduction of the

extraction hood power up to the switching off. The reduction of the extraction hood

power is carried out every 1 minute. The not reduction of the pollution level extends

the working time of the extraction hood at the same power by another minute. The

appearance of the pollution on the higher level causes an immediate rise of the

extraction hood power. The discovery of the maximum pollution level puts the

extraction hood into operation for one minute on the speed 4 and if after this time the

pollution level is reduced, the fan starts to work for a minute on the speed 3. A further

decline in the air pollution causes the reduction of the motor speed up to the switching

off.

-Switching-on of the automatic work (of the odour sensor): Hold pushbutton "+"

pushed approximately 2 seconds (A appears). Exit from the automatic mode: keep

the pushbutton "+" pushed approximately 2 seconds (0 appears).

- Timer: There is a possibility of pre-programming the automatic switching off of the

extraction hood fan in a moment chosen at own discretion in the area of 10 to 90

minutes in 10 minute steps.

-To activate the function of the programming switch on the extraction hood motor

with the pushbutton+ on the desired speed and then push the pushbutton T. A

flashing number appears on the display device to inform us that the control unit has

entered into the time programming mode.

IO 00236