4

1. Introduction

We have the pleasure to deliver a Granberg Interior Verti lift unit for installation in wall cabinets.This is an electrically oper-

ated lifting and lowering system for installation in new or existing wall cabinets.It can be used separately, or together with the

Granberg work top units, and it becomes then a total adaptation of the kitchen.The lift is suitable for all wall cabinets of

various makes,which are made according the standards EN 1116 and EN 1153.

Only authorized persons may use the Verti!

Authorization means obligation to read and follow the instructions.

It is very important that you read and understands the instructions before you use Verti.

If you have any questions - contact your supplier.

This Instruction manual shall be available for all concerned persons,be kept in a protected place and shall follow the product, if

it is moved to another installation site or another house or apartment owner.

Correct use, operation, inspections and maintenance are

decisive for efficient and safe work.

2. Declaration of Conformity with EU-directive

This product is CE-marked and is granted to conform to the basic safety and operation requirements, in accordance with de

actual Machinery, EMC- and Low voltage Directives. A separate “CE-Declaration of Conformity” is available in section 13.

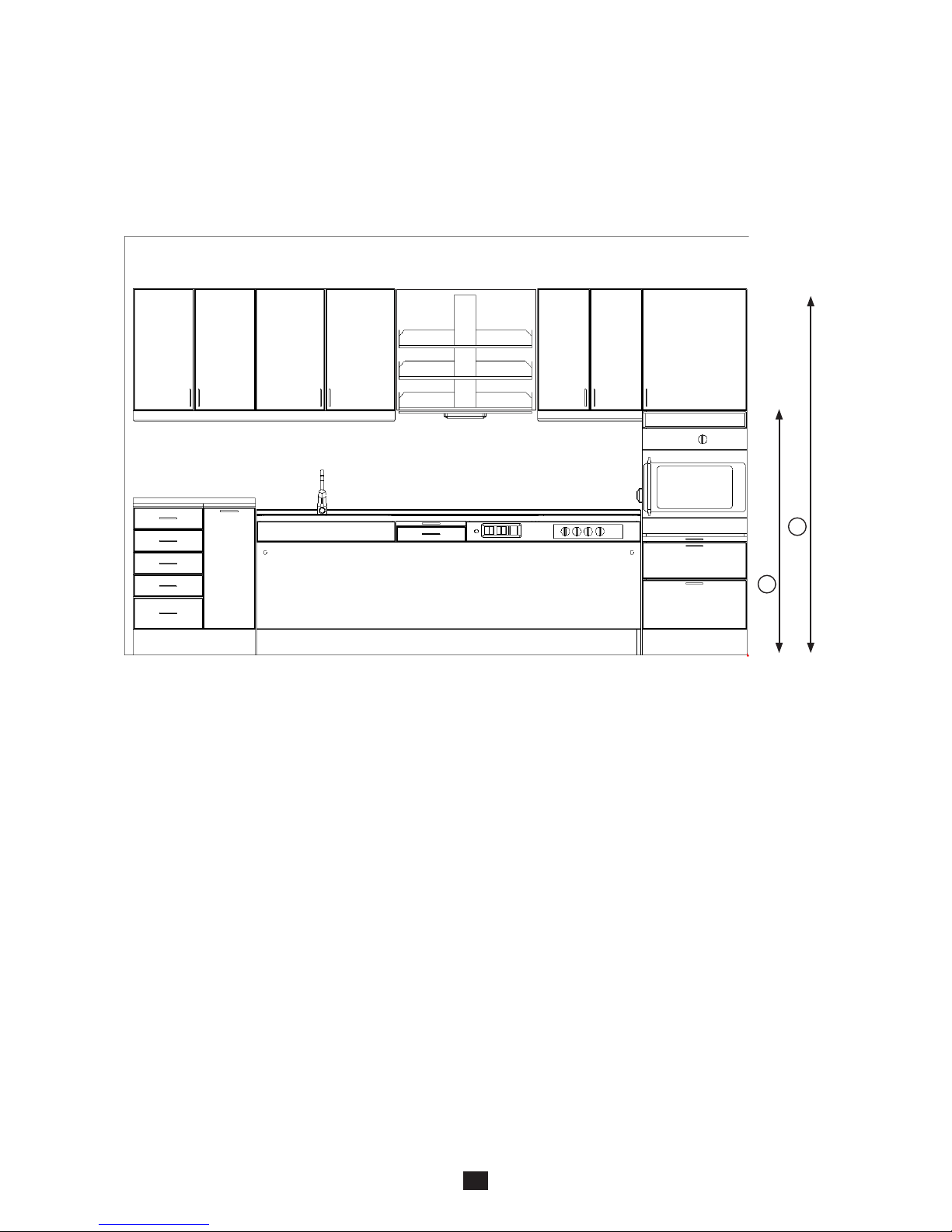

3. Intended use - Technical data

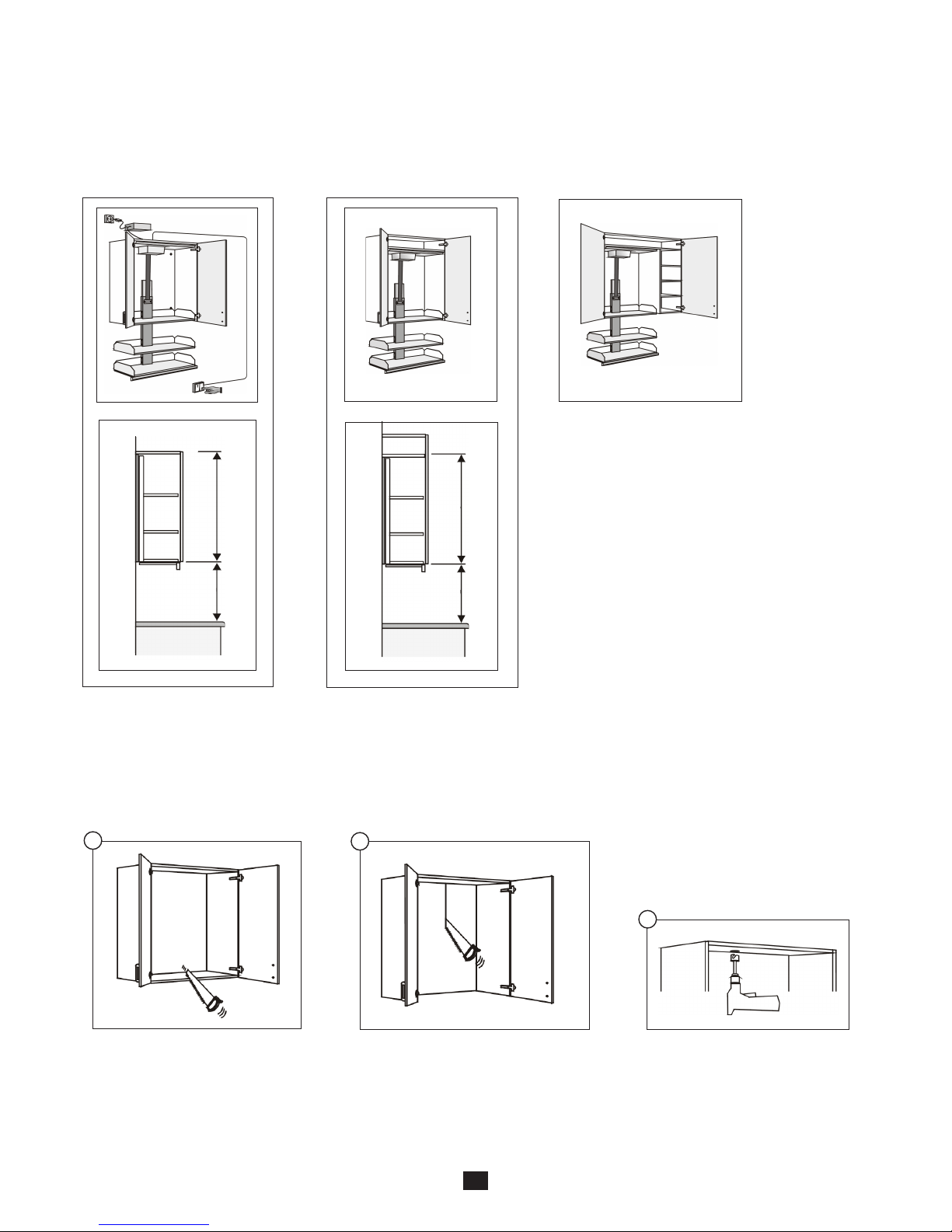

The Verti Cabinet lift unit is intended to achieve a convenient location to put or pick of normal kitchen cabinet items, e.g. dry

groceries and household objects, by means of manoeuvring the shelf system vertically.Verti is mounted in a kitchen cabinet

of massive wood or of lacquered or laminated chipboards.The operation shall be indoors, under normal housing conditions

regarding temperature,humidity and lighting.

Verti is not intended for use in moist environments.

The Verti Cabinet lift unit is delivered for installation in a new cabinet frame,comprising sides and a top board,or for

installation in existing cabinet.The shelves and the bottom board and possible backboard must be demounted before the

Verti is installed.

It is assumed that the wall cabinet is made according the standards EN 1116 and EN 1153.

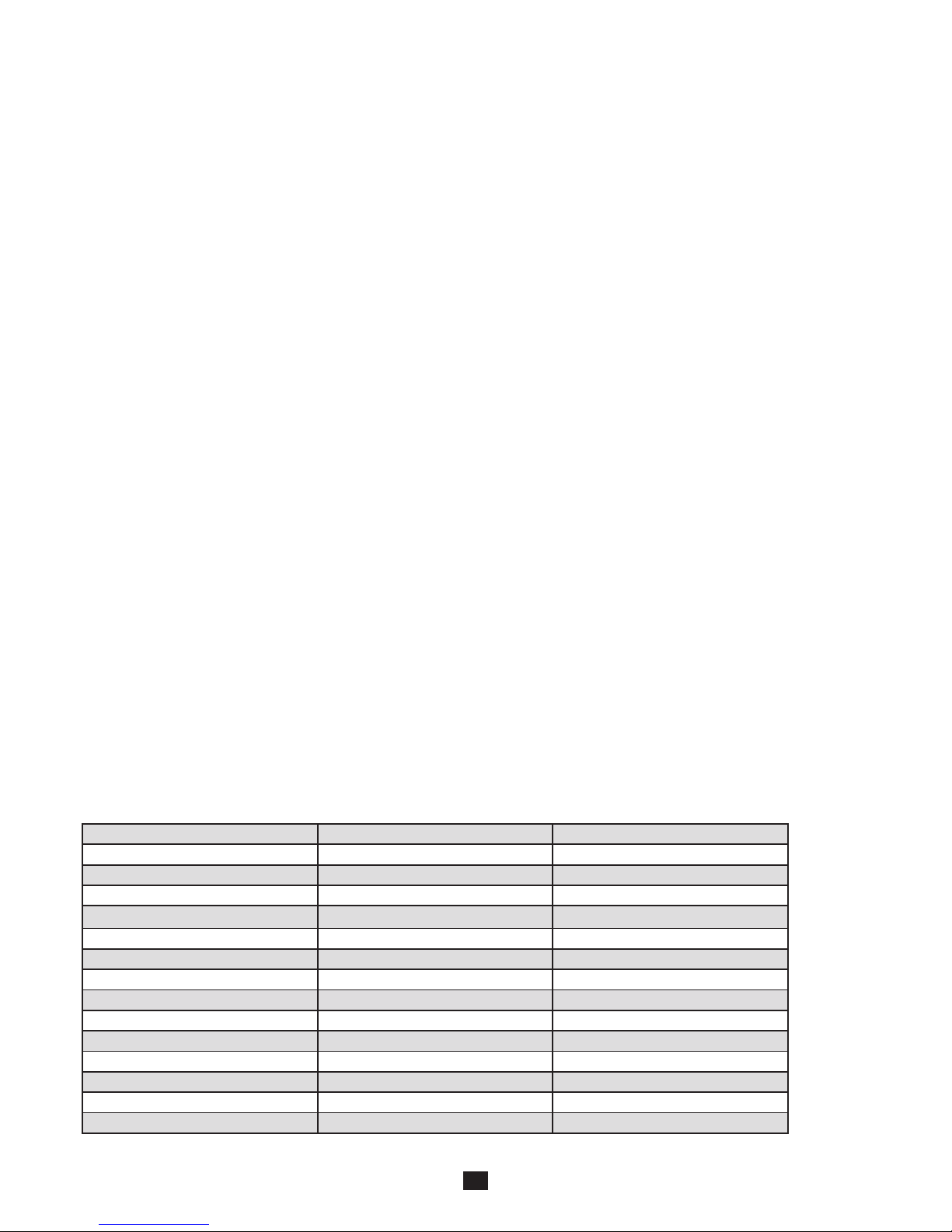

Technical data, Verti 830 / 831

Model 830 831

Cabinet width (inside) 360 - 960 mm 360 - 960 mm

Length of shelves 306 - 906 mm 306 - 906 mm

Cabinet height Min. 700 mm Min. 700 mm

Cabinet depth, min 265 mm 310 mm

Depth of shelves 242 mm 286 mm

Vertical stroke, max 470 mm 470 mm

Time for a lift or lowering stroke, approx. 10 s 10 s

Mains voltage* 120 V 1,5 A / 230 V 0,5 A 120 V 1,5 A / 230 V 0,5 A

Power consumption* 180 W / 105 W 180 W / 105 W

Max no. of full work cycles per hour 6 6

Control and lighting voltage 24 V DC 24 V DC

Weight including shelves, max. size 28 kg 28 kg

Max load in a cabinet 40 kg 40 kg

Noise pressure Less than 70 dB(A) Less than 70 dB(A)

* The voltage depends on which model that is delivered.