Fire Bowls and Inserts Premium Line

Automated Operation Page 5

Section 3. Installing the Grand Effects®

Fire Bowls

WARNING

Risk of Electrical Shock or Electrocution. This fire bowl must

be installed by a licensed or certified electrician or a qualified pool

serviceman in accordance with the National Electrical Code®(Canadian

Electrical Code, in Canada) and all applicable local codes and

ordinances. Improper installation will create an electrical hazard, which

could result in death or serious injury to pool or spa users, installers or

others due to electrical shock, and may also cause damage to property.

Always disconnect the power to the bowl at the circuit breaker before

installing or servicing the bowl. Failure to do so could result in death or

serious injury to serviceman, pool or spa users or others due to electrical

shock.

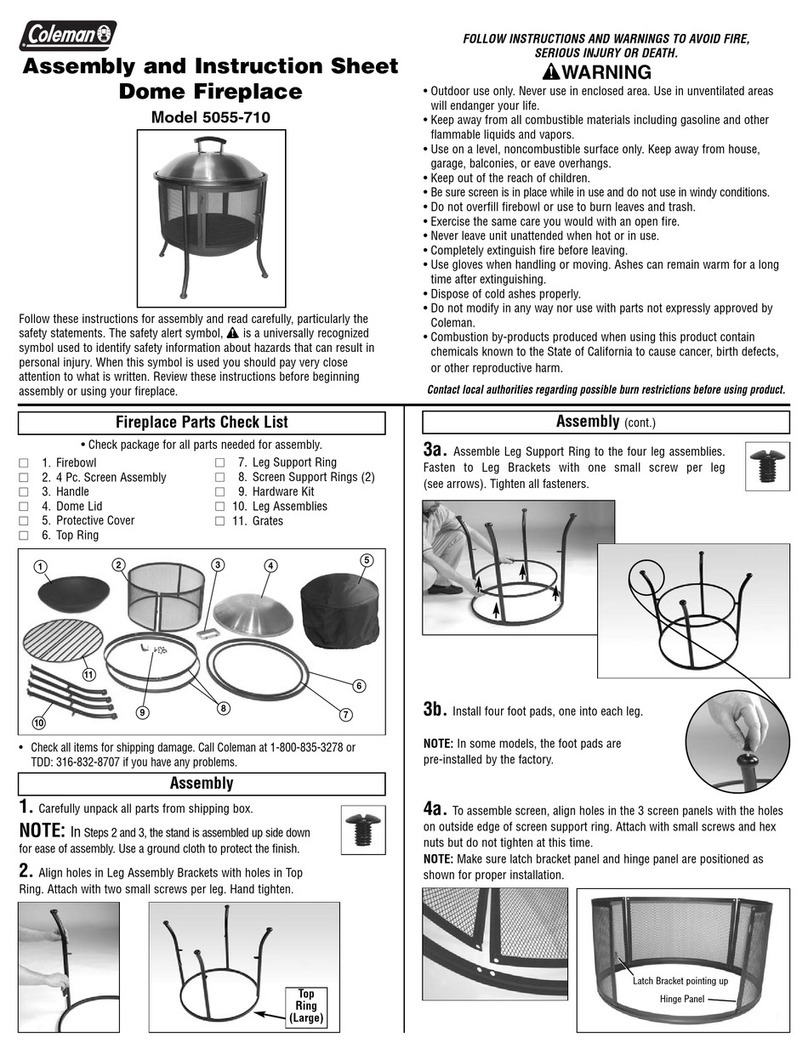

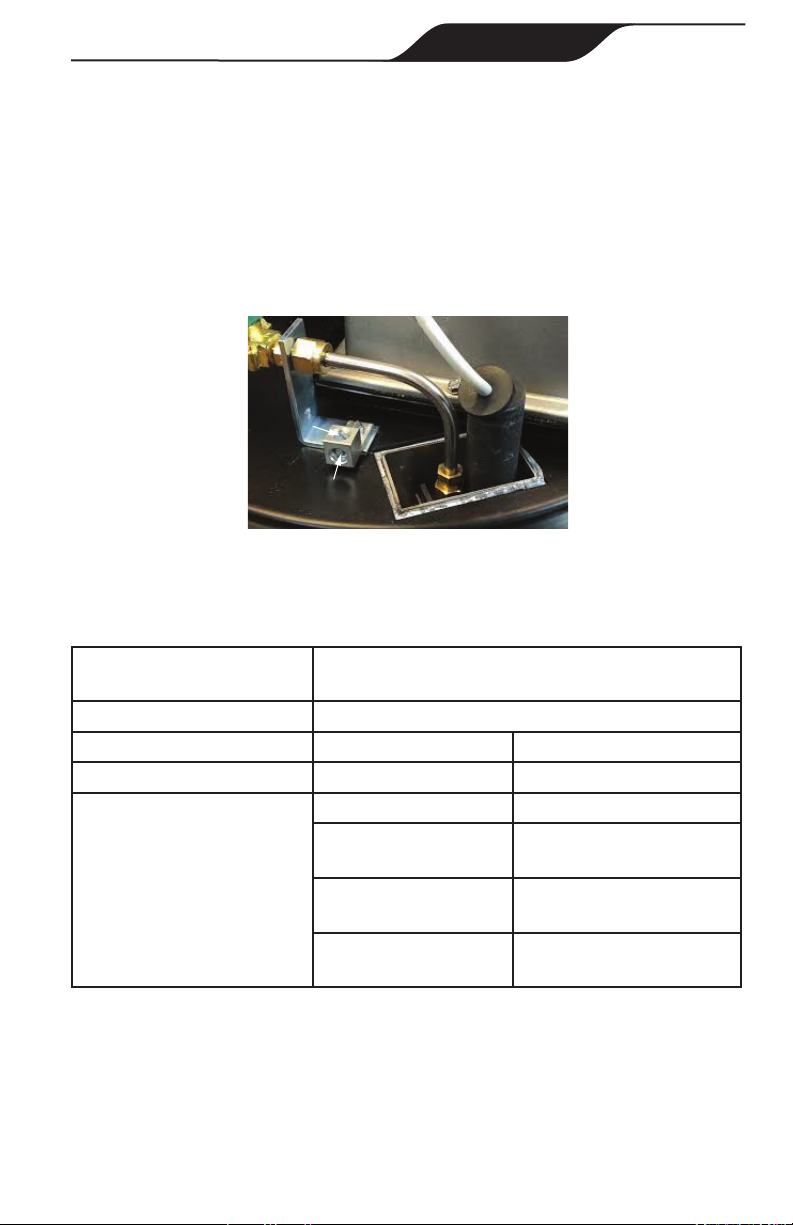

3.1 Preparing the Fire Bowl for Installation

NOTE: The installer must complete preparatory steps before re bowl is

installed.

The National Electrical Code (NEC®) allows listed low-voltage gas fired-

luminaires, decorative fireplaces, fire pits, and similar equipment using low

voltage ignitors that do not require grounding, and are supplied by a listed

transformer / power supply with outputs that do not exceed the low-voltage

contact limit (15 V RMS ac, 30 V continuous dc) to be permitted to be

located less than 1.5 m (5 ft) from the inside walls of the pool.

Metallic equipment, including metallic gas piping, shall be bonded in

accordance with the National Electrical Code in the US, and Canadian

Electrical Code in Canada.

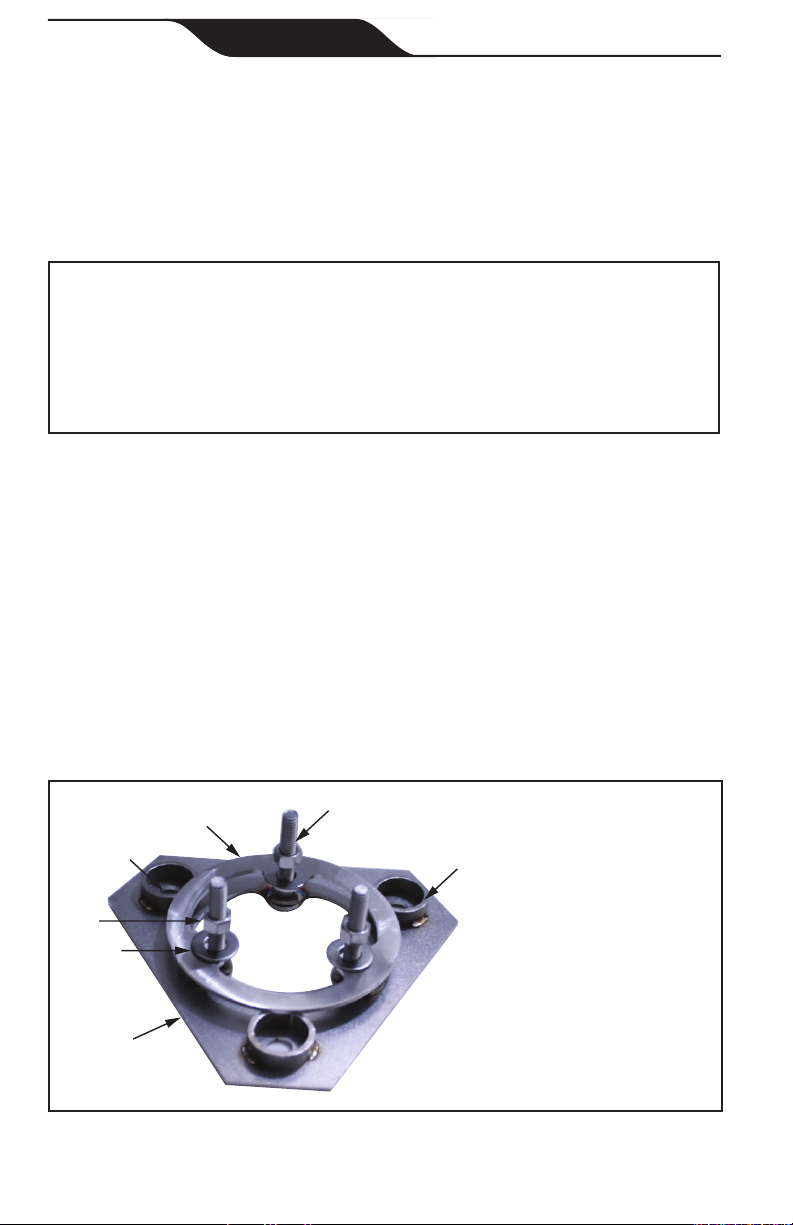

BONDING

In the United States the National Electrical Code® (NEC®) and in Canada

the Canadian Electrical Code (CEC), require that all metallic components

of a pool structure, including reinforcing steel, metal fittings and above

ground components be bonded together (forming an equipotential bonding

grid) with a solid copper conductor not smaller than an 8 AWG (6 AWG in

Canada).