Fabric

Suction scale

Pure Silk & wool Knitted Fabric

4-6 7-9

Tatting & Jeans

2-3

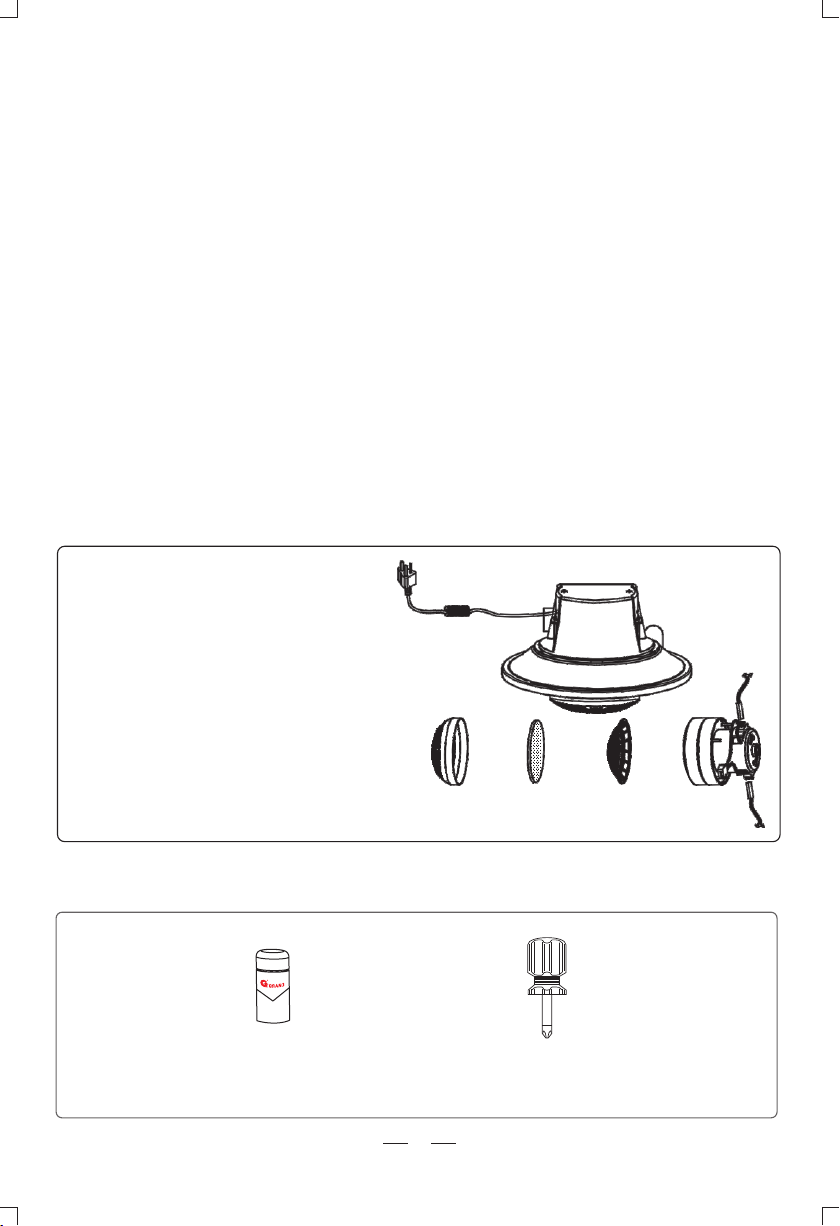

◆ Description of operation

操作使用方法

Pefer to the following form 列表 如 下作为 参 考

面料

吸气量刻度

真丝面料,毛制面料 针织面料

梭织面料,牛仔服面料

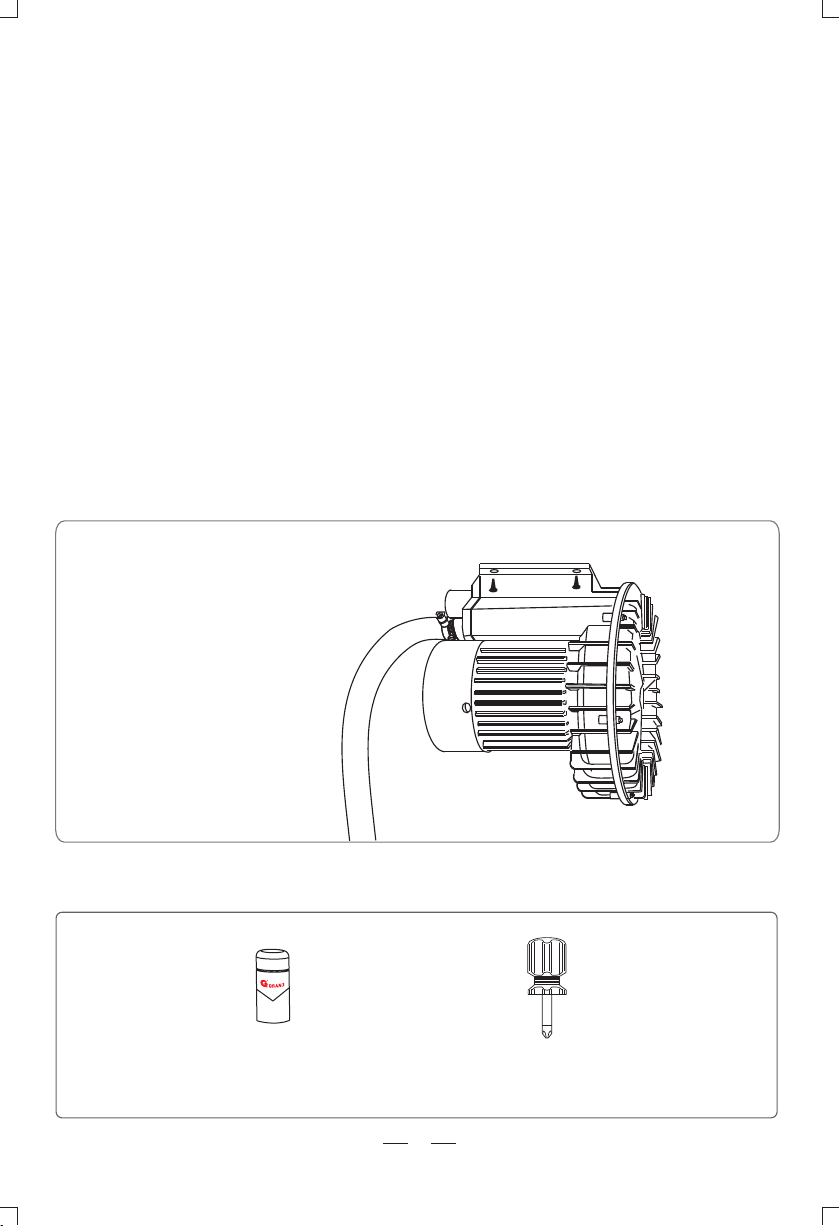

◆ Trimmer clipper maintenance

剪线刀的保养

2

1、

teeth of blade and cut off.

成衣的线头沿刀齿方向由左向右平行移动即可达到剪线目的。

2、In the light of laborer's habit, he she can casually adjust the gap between blade head and operator so as to mitigate

worker's labor strength.

根据操作习惯,可任意调节刀片组对操作人员的距离,以减轻疲劳。

3、In the light of different cloth material, select different suction speed so as not to damage any cloth material.

根据不同的面料选择不同的刀型和风速,以免对面料造成损伤。

Move the garment along with the direct of blade teeth from left to right, whilst the thread ends are sucked into the

1、

correct position exactly. Active blade tip is 0.604mm shorter than fixed one. Such adjustment only needs to release

screw with spring washer and in parallel impel active blade.

2、Whilst adjustment for clipper blade wing guard, please retain approximate 1.28mm gap between wing guard and

clipper blade tip after completion of the blade installation; if the cloth is extremely thin, 0.64mm adjustment is also

acceptable, such manner should avoid any damage of garment or over-lock thread whilst cutoff.

3、Blade tip and wing guard shall retain 0.5mm gap, that is to say, wing guard is 0.5mm higher than blade tip;

however, garment or over-lock thread is easily damaged if they both are equal to each other at height; as for some

comparatively thinner garment or requirement for over 2mm thread length after cut operation, the gap between

wing guard and blade tip must be adjusted into comparative larger setup, herein, only release screw (see Diagram 3)

and push down blade assembly until onto appropriate position, replace some thicker wing guard is also acceptable if

available.

4、In case clipper blade is blunt, please release the screw tightened on the blade, review if any peculiar substance exists

between blade and blade teeth, if some accumulative dirt completely exists which results in unsuitable position

whilst thread head feeds into blade, must immediately clean up it completely; also review the stress of tension

spring, first left hand holds on fixed blade, and then right thumb and first finger impel active blade, it is ok if feeling

3-3.5kg push force, otherwise, please rectify the spring pressure or replace new one.

5、Once some special sound such as “Dadada” takes place on the blade head, please release the screw tightened on the

blade, review the matching gap between eccentric block and fixed blade, immediately replace the eccentric block if

too larger matching gap, whilst checking up if some axial gap exists, also immediately reset it if too larger

clearance.

6、No use sewing machine oil or WD-40 instead of grand special thread trimmer oil since these kinds of oil shall

shorten the life of blade, however, grand lubricant is one of composite oil with quiet fine, higher specification value,

easier solubility to water and mobile viscosity, also beneficial for improvement for blade life.

Whilst re-installation for clipper blade, firstly assure the active blade tip and fixed blade are put together to the