4

This manual is intended to guide

engineers in the installation and

maintenance of Grant VORTEX Pro

External modules. A User guide for the

operation of this boiler is attached to

the reverse of this manual.

The following special text formats are

used in this manual for the purposes

listed below:

Warning of possible human injury as

a consequence of not following the

instructions in the warning.

Caution concerning likely damage

to equipment or tools as a

consequence of not following the

instructions in the caution.

Note text. Used for emphasis or

information not directly concerned

with the surrounding text but of

importance to the reader.

1.1 How a Condensing Boiler Works

During the combustion process,

hydrogen and oxygen combine to

produce heat and water vapour. The

water vapour produced is in the form

of superheated steam in the heat

exchanger. This superheated steam

contains sensible heat (available heat)

and latent heat (heat locked up in the

flue gas). A conventional boiler cannot

recover any of the latent heat and

this energy is lost to the atmosphere

through the flue.

The Grant VORTEX Pro condensing

boiler contains an extra heat

exchanger which is designed to

recover the latent heat normally lost by

a conventional boiler. It does this by

cooling the flue gases to below 90°C,

thus extracting more sensible heat

and some of the latent heat. This is

achieved by cooling the flue gases to

their dew point (approximately 55°C).

1Introduction

NOTE

!

CAUTION

!

WARNING

!

To ensure maximum efficiency, the boiler

return temperature should be 55°C or

less, this will enable the latent heat to be

condensed out of the flue gases.

• The boiler will achieve net thermal

efficiencies of 100%.

To achieve maximum performance

from the Grant Vortex Pro boiler, it is

recommended that the heating system

is designed so that a temperature

differential of 20°C between the flow

and return is maintained. The use of

modulating circulating pumps (now

widely available) and effective control

systems should be considered.

The Grant VORTEX Pro boiler will

however still operate at extremely

high efficiencies even when it is not

in condensing mode and therefore is

suitable for fitting to an existing heating

system without alteration to the radiator

sizes. The boiler is capable of a maximum

flow temperature of 75°C.

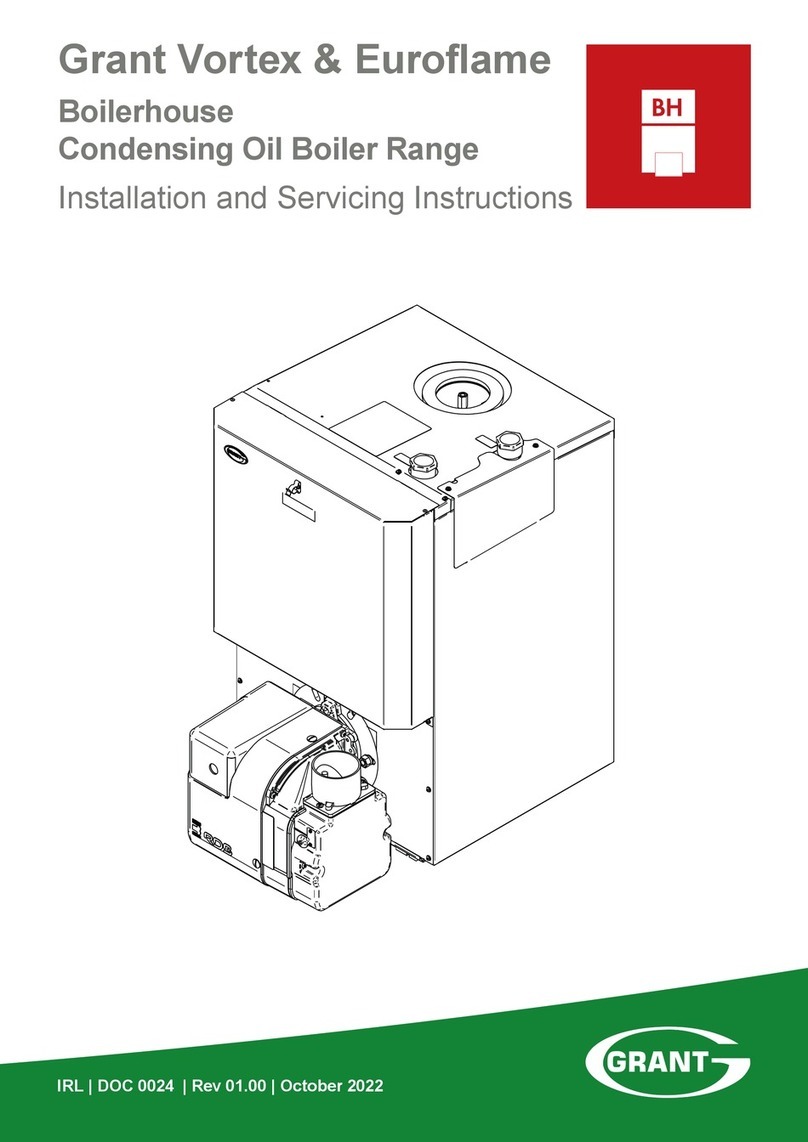

1.2 Boiler Description

Grant VORTEX Pro External modules

have an insulated weatherproof

enclosure made of galvanised steel with

a powder coated finish, and are designed

for external installation, either against a

wall or free standing some distance away

from the property, as required.

The External modules are part of the

Grant range of automatic pressure jet

oil boilers which have been designed for

use with a fully pumped central heating

system with indirect domestic hot water

cylinder. They are not suitable for use

with either a direct cylinder or a 'primatic'

cylinder or gravity hot water.

The boilers are suitable for use on

open vented or sealed central heating

systems.

All models are supplied with the

control panel and burner factory fitted.

The factory fitted low level discharge

flue system can be adjusted on site for

either rear, left hand or right hand flue

outlet position as required.

Introduction

An external conventional flue (Green)

system (Figure 9-3) is also available

from Grant UK. Refer to Section 9.2 for

further details.

A Hybrid flue (Green/Orange) system

(Figure 9-1) is also available which

allows the External module to utilise

an existing chimney stack. Refer to

Section 9.2 for further details.

Where an existing chimney is to be

lined - Grant recommends the use

of the Grant ‘Orange’ flue system,

specifically designed for the Vortex

range of condensing boilers. Refer to

Section 9.2 for further details.

Where a rigid conventional flue is

required, Grant recommends the use

of the Grant 'Green' and 'Orange'

flue system components. As no flue

adaptor is supplied with the boiler

it will be necessary to purchase the

correct Grant Starter Elbow in order

to connect this system to the boiler.

Refer to Section for further details.

The 'Green' and 'Orange' system

components can be used to construct

a flue of maximum vertical height 19

metres.

The flue system materials and

construction MUST be suitable

for use with oil-fired condensing

boilers. Failure to fit a suitable

conventional flue may invalidate the

warranty on the boiler.

A horizontal system - see Figure

9-4, is also available up to 3 metres -

components available:

• Straight starter

• Extensions 150 mm, 250 mm, 450 mm

and 950 mm

• Adjustable extension 195 to 270 mm

• 45° elbow

• Straight terminal

NOTE

!