Graphic Products Logan F700-1 User manual

Instruction Manual

WALL MOUNT

MULTI-MATERIAL

CUTTER

Model F700-1

G1089 1/22

www.logangraphic.com

Description

The Model 700-1 has been designed as

a full featured Multi-Material Wall

Mounted Cutter. Features include

interchangeable cutting tools for glass,

matboard / foamboard, and plastic.

Large capacity 60” cutting length, 48”

material bed, smooth bearing guided and

counter-balanced cutting head, solid all

metal construction makes this an ideal

machine for your framing requirements.

WALL MOUNT

MULTI-MATERIAL CUTTER

1. Cutting Bar / Cutting Head Assembly

2. Left Cutting Bed

3. Right Cutting Bed

4. Steel Gusset

5. Support Arm

6. Top Mounting Bracket

7. Bottom Mounting Bracket

8. Side Mounting Bracket

9. Material Clamp Assembly

10. Production Stop

11. Glass Cutting Tool

12. Plastic Cutting Tool

13. Mat Board Cutting Tool

14. Counter-Weight & Cable

15. Wall Screws (9)

16. Wall Washers (9)

17. Wall Mollies (9)

18. Mounting Nuts (8)

19. Support Arm Screws (4)

20. Support Arm Wrench

21. Gusset Screws (7)

22. Gusset Wrench

23. Debris Brush

24. Mat Blade 5-Pack

25. Glass Cutting Oil

26. Parts Tray

27. Adjustment Wrench

28. Pulley

1

2 3

4 5

69

10

11 12 13

14

23

24

25

26

28

27

7

88

Instruction Manual Model F700-1

Identification of

Carton Contents:

G1089 1/22

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com

2

15

16

17

18

19

21

20

22

BLADES

WALL MOUNT

MULTI-MATERIAL CUTTER

G1089 1/22

Cutting Bar

Counterweight

Material Clamp

Gusset

Left Cutting Bed

Glass Cutting Oil

Adjustment

Wrench

Debris Brush

Mat Blades Board Cutter Glass Cutter Plastic Cutter

Right Cutting BedProduction Stop

Cutting Head

Support Arm

Instruction Manual Model F700-1

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com

3

Machine Components

WALL MOUNT

MULTI-MATERIAL CUTTER

G1089 1/22

Instruction Manual Model F700-1

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com

4

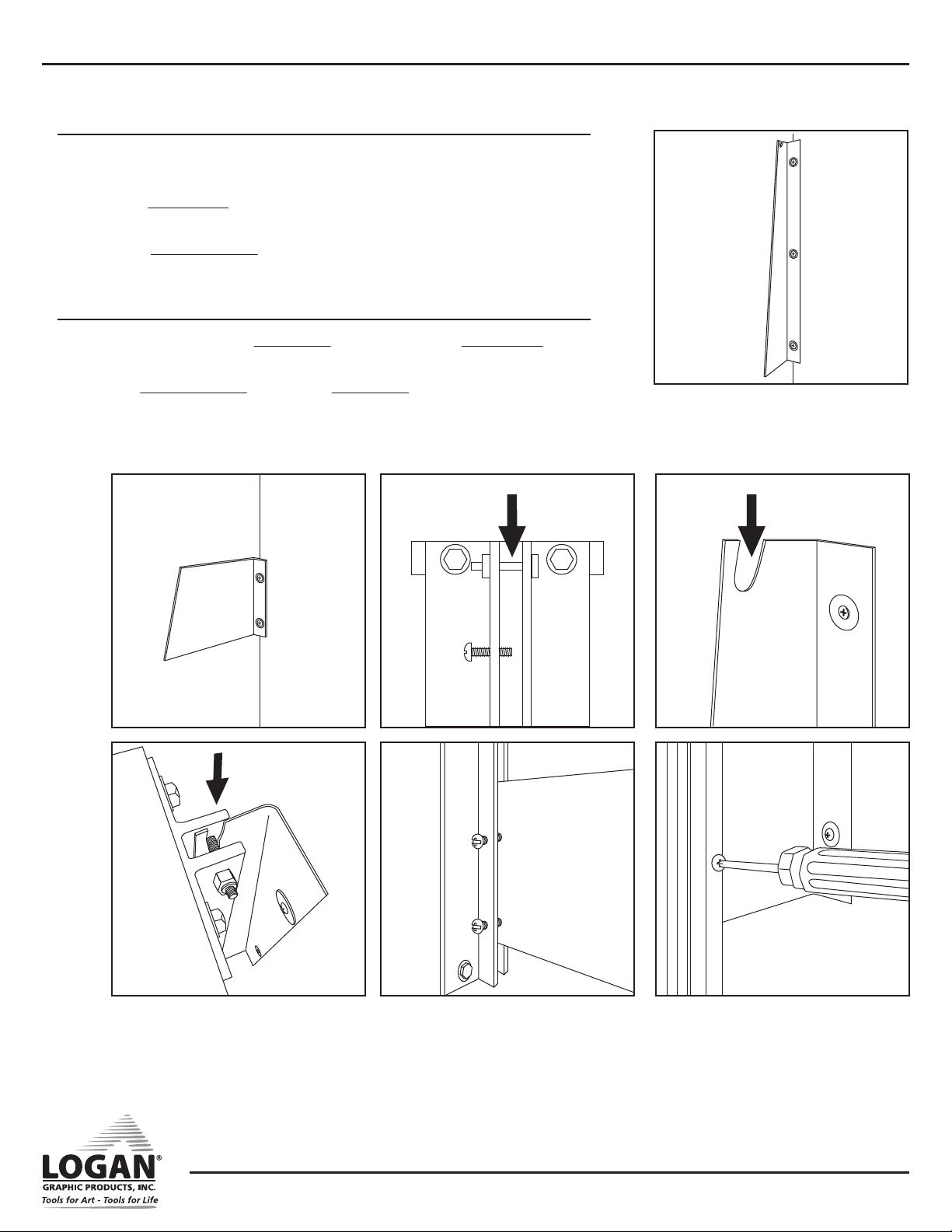

Installation

Mounting Top and Bottom Brackets

1. For drywall / wood wall, use a stud finder to locate vertical stud at

preferred machine location.

2. Using a level, draw a vertical line at stud location and mark five drill

hole locations on vertical line per chart (Fig. 1)

66”

27”

15”

15”

32”

Vertical Line

Stud Location

Floor

Drill Hole

Locations

4”

Tools needed for installation

• Step Ladder

• Level (24”-36”)

• Drill

• 1/8” drill bit

• 1/4” drill bit

• 1/4” masonry bit (for masonry wall)

• Hammer

• Phillips head screwdriver

• Tape measure

• Stud finder

• Carpenters square 16” x 24”

• Pencil

• Adjustable wrench or 7/16” wrench

Fig. 1

WALL MOUNT

MULTI-MATERIAL CUTTER

G1089 1/22

Instruction Manual Model F700-1

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com

5

Mounting Top and Bottom Brackets

4. Drill holes using 1/8” drill bit for wood or 1/4” masonry bit for masonry

wall (insert wall mollies using hammer).

5. Mount Top Bracket aligning top three holes on wall with holes in bracket

and secure using washers and screw (Fig. 2).

6. Mount Bottom Bracket aligning bottom two holes on wall with holes in

bracket and secure using washers and screws (Fig. 3).

Mount Cutter Bar

1. Carefully fit top pin in Cutting Bar (Fig. 4) into slot in Top Bracket

(Fig. 5) and align bracket edges along bar assembly edge (Fig. 6).

2. Align Bottom Bracket edge along Cutting Bar side (Fig. 7).

3. Tighten five (5) Mount Screws (Fig. 8).

Fig. 2

Fig. 6

Fig. 4Fig. 3 Fig. 5

Fig. 7 Fig. 8

WALL MOUNT

MULTI-MATERIAL CUTTER

G1089 1/22

Instruction Manual Model F700-1

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com

6

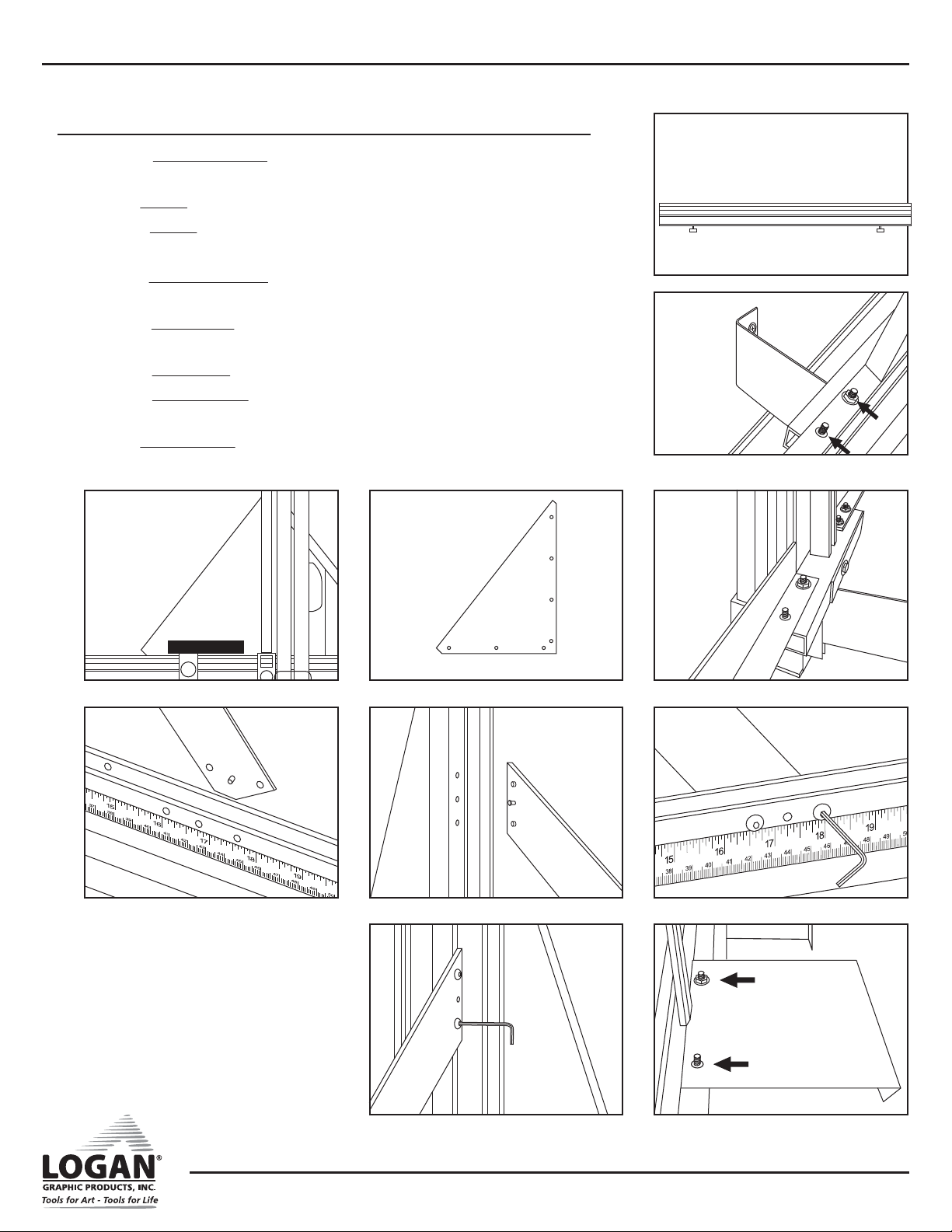

Mounting Cutting Beds

1. Attach Left Cutting Bed (long 48”) (Fig. 9) onto mount bar studs and

secure with two (2) mount nuts (Fig. 10).

2. Align Gusset with left cutting bed and cutting bar assembly (Fig. 11).

3. Attach Gusset with seven (7) flat head screws.

*Note* Attach screws in the order shown (Fig. 12).

4. Attach Right Cutting Bed (shorter 24”) onto mount bar studs and secure

with two (2) mount nuts (Fig. 13).

5. Attach Support Bar by aligning pins in support bar with holes in Right

Cutting Bed and Cutting Bar (Fig. 14 & 15).

6. Secure Support Bar with four (4) screws (Figs. 16A & 16B).

7. Attach Side Brackets onto cutting bed studs with four (4) mount nuts

(Fig. 17).

8. Align Side Brackets to wall, and mark holes with a pencil.

Fig. 9

Fig. 10

Fig. 11 Fig. 12

1

254

7

6

3

Fig. 13

Fig. 14 Fig. 15 Fig. 16A

Fig. 16B Fig. 17

WALL MOUNT

MULTI-MATERIAL CUTTER

G1089 1/22

Instruction Manual Model F700-1

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com

7

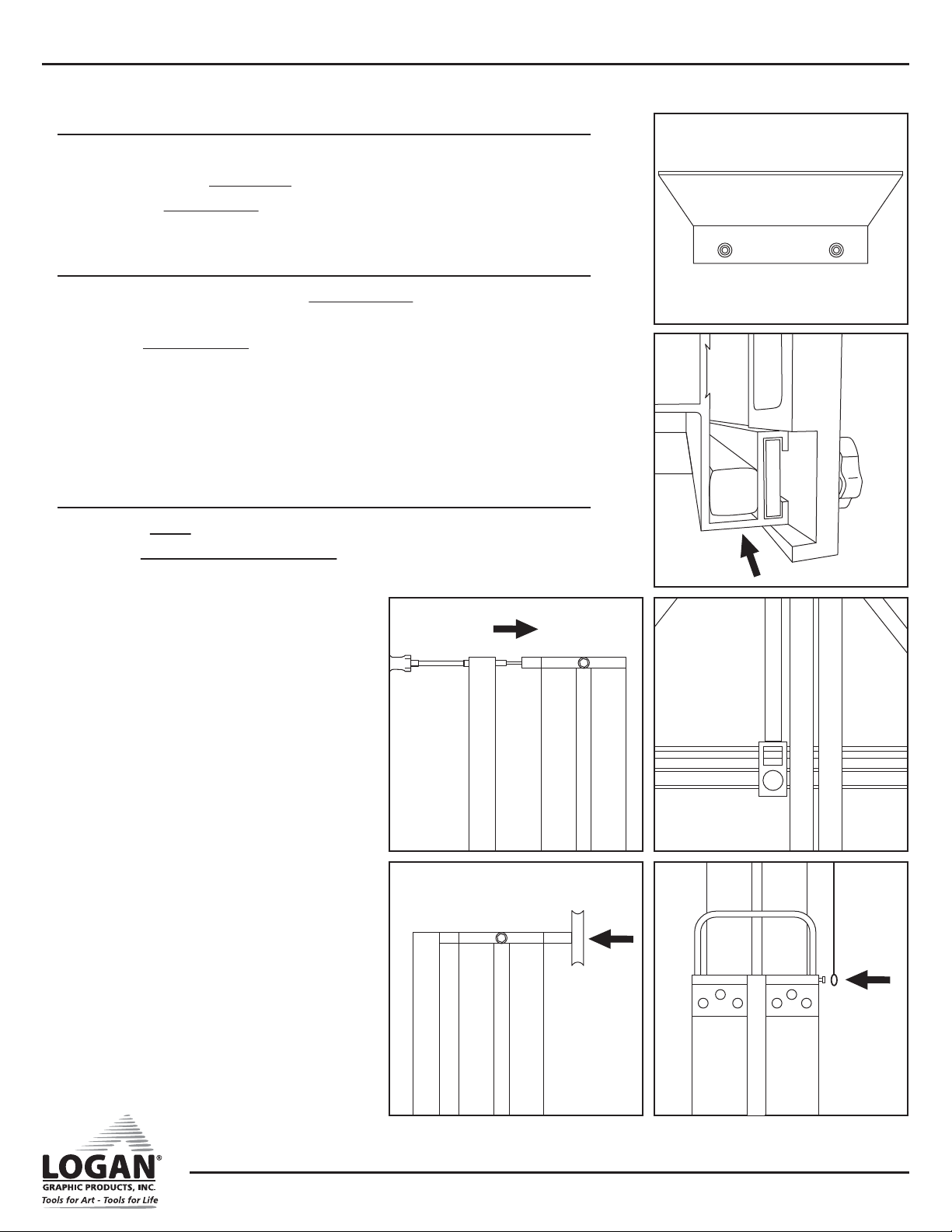

Mounting Cutting Beds

9. Drill marked hole centers.

10. Insert four (4) Wall Mollies into wall holes and hammer flush (Fig. 18).

11. Secure Side Brackets to wall with screws and washers.

Install Material Clamp

1. Holding clamp vertically, slide Material Clamp bracket lock nut into Left

Cutting Bed (Fig. 19).

2. Slide Material Clamp until top mounting screw aligns with top mount

block.

3. Attach top mounting screw (Fig. 20).

4. Adjust clamp to be parallel with guide bars (Fig. 21).

5. Tighten clamp bracket knob.

Attach Counter-Balance Weight Bag

1. Attach Pulley to top mount block (Fig. 22).

2. Hook Counter-Balance Weight Bag onto cable post located on right side

of cutting head (Fig. 23).

Fig. 18

Fig. 19

Fig. 21

Fig. 23

Fig. 20

Fig. 22

WALL MOUNT

MULTI-MATERIAL CUTTER

G1089 1/22

Instruction Manual Model F700-1

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com

8

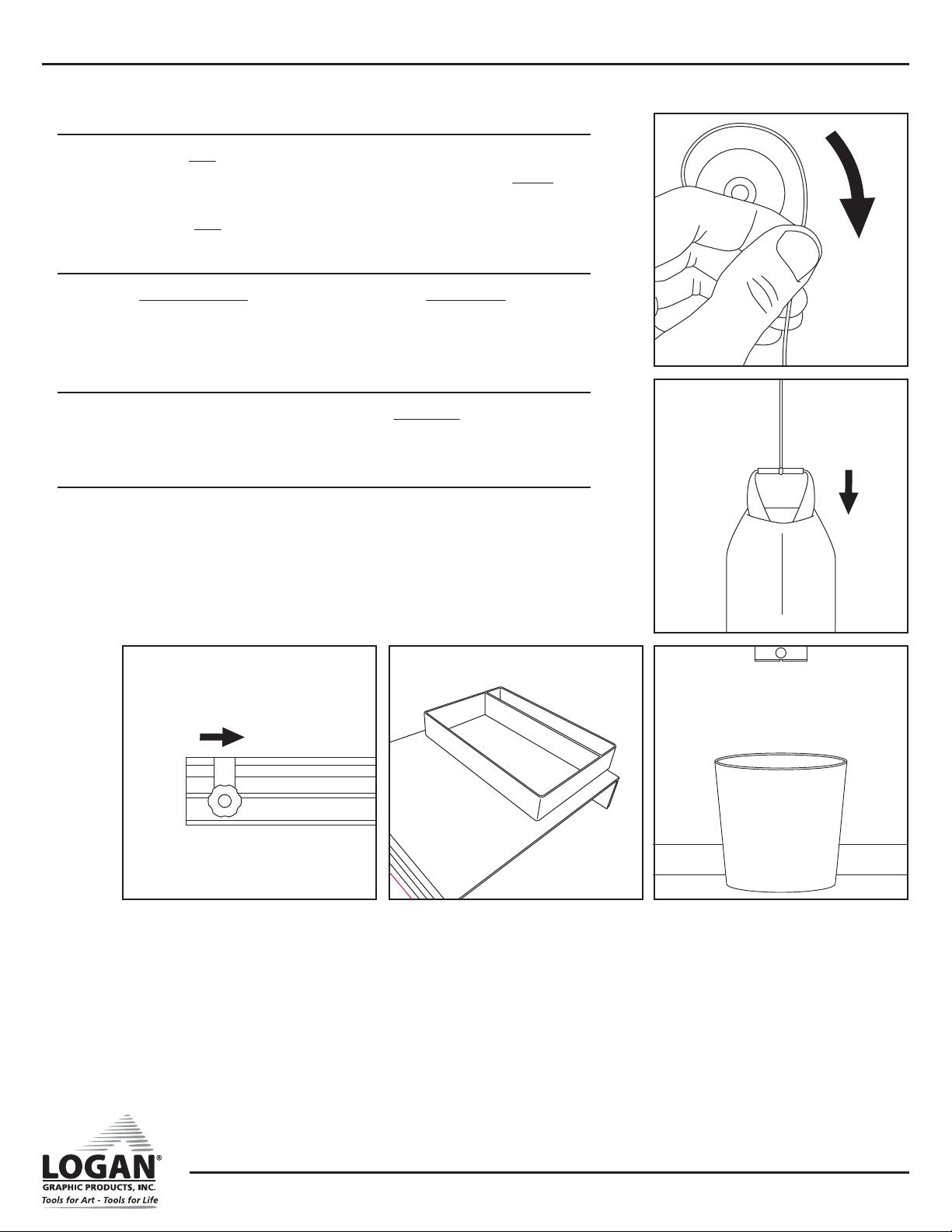

Attach Counter-Balance Weight Bag

3. Holding the Bag in your right hand and keeping tension on the cable

with your left hand, step up on ladder and loop cable over Pulley with

left hand (Fig. 24).

4. Slowly lower Bag until cable is taut (Fig. 25).

Install Production Stop

1. Slide Production Stop lockplate into right or left Cutting Bed and slide to

desired location (Fig. 26).

2. Tighten stop knob to secure.

Install Parts Tray

1. Remove adhesive backing from bottom of Parts Tray.

2. Stick onto right side bracket (Fig. 27).

Use Trash Can

It is recommended that you place a small trash can under bottom of

cutting bar to catch debris (Fig. 28).

Fig. 24

Fig. 25

Fig. 28Fig. 27Fig. 26

WALL MOUNT

MULTI-MATERIAL CUTTER

G1089 1/22

Instruction Manual Model F700-1

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com

9

Cutting Tool Details

The machine includes three separate interchangeable cutting tools:

• Glass Cutting Tool

• Board Cutting Tool

• Plastic Cutting Tool

Glass Cutting Tool (Red Tip)

• Cuts glass up to 1/4” thick.

• Features a turret design which carries six (6) carbide wheels. Wheels are

numbered 1-6 (Replacement part F57).

• Includes cutting oil for best results.

• Glass wheels “score” glass which is then cracked to separate pieces.

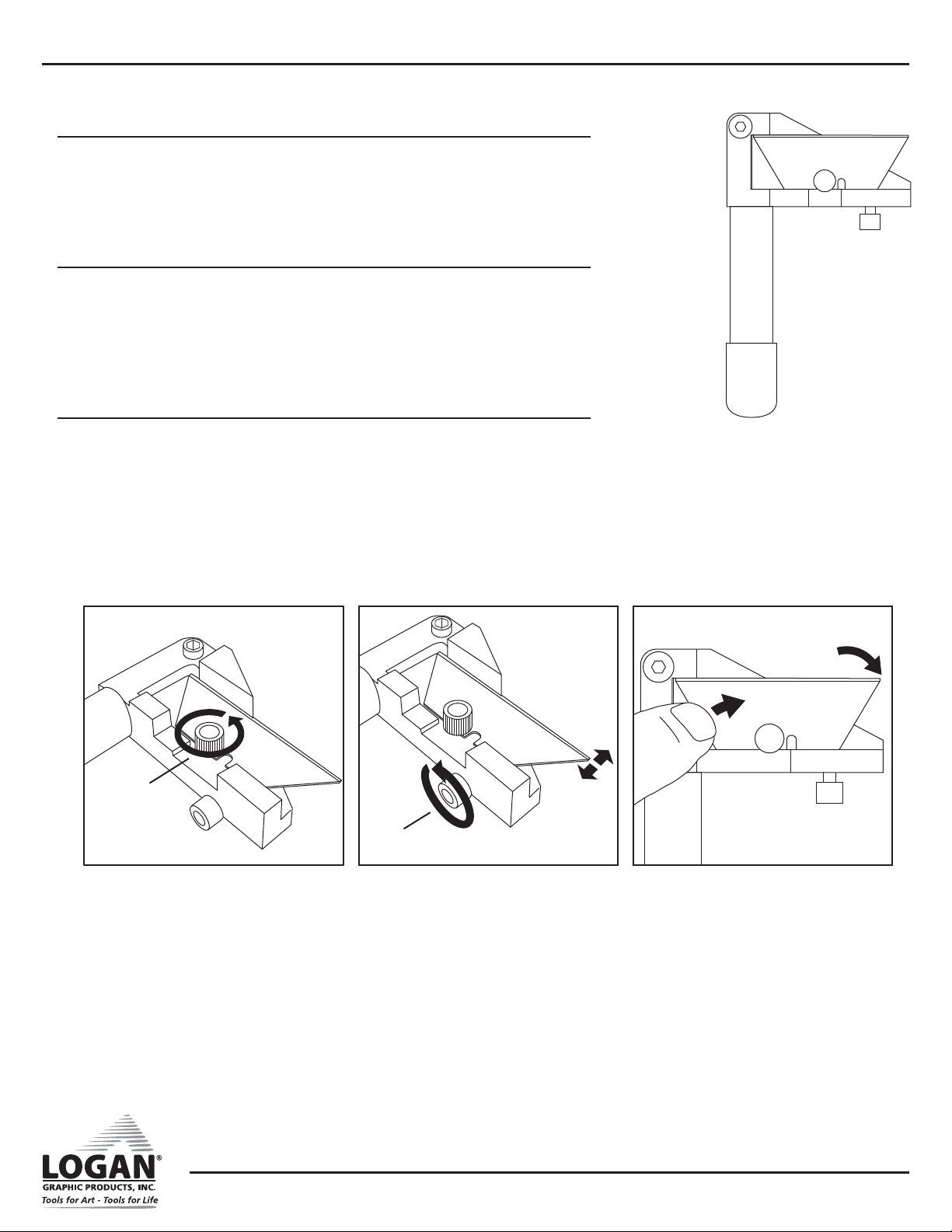

Glass Cutting Tool Wheel Change

1. Loosen turret nut and turret rotation screw (Fig. 29).

2. Rotate turret until next number appears (Fig. 30).

3. Re-tighten both nut and screw.

Glass Cutting Tool Turret Change

1. Loosen turret rotation screw one full turn.

2. Remove turret nut.

3. Push turret screw to remove turret (Fig. 31).

4. Replace new turret (Fig. 32).

5. Rotate turret to setting “1” or “I”.

6. Tighten turret rotation screw.

7. Replace and tighten turret nut.

Fig. 32Fig. 31Fig. 30

Fig. 29

Nut

Rotation

Screw

WALL MOUNT

MULTI-MATERIAL CUTTER

G1089 1/22

Instruction Manual Model F700-1

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515 www.logangraphic.com

10

Board Cutting Tool (Yellow Tip)

• Cuts up to 1/2” foam board, mat board, gator board, and cardboard.

• Uses standard utility blade (Replacement Number F58).

• Uses both ends of blade.

• Features blade depth adjustment screw.

Board Cutting Tool Blade Change

1. Remove blade screw (Fig. 33).

2. Rotate or replace blade.

3. Replace blade screw but do not tighten.

4. Push back of blade to reposition blade against depth screw.

5. Tighten blade screw.

Board Cutting Depth Adjustment

1. To adjust, loosen blade screw (Fig. 34).

2. Push back of blade to reposition it against depth screw (Fig. 35).

3. Tighten blade screw.

Fig. 33

Blade Screw

Depth Screw

Fig. 34 Fig. 35

Table of contents

Popular Cutter manuals by other brands

Milwaukee

Milwaukee HEAVY DUTY M12 FCOT Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual