GRAPHTEC Craft ROBO CC100-20 User manual

Craft ROBO

SERVICE MANUAL

MANUAL NO. CC100-UM-251

CC100-20

�

CC100-UM-251-02-9370

iCC100-UM-251-9370

HISTORY OF REVISIONS

No. Date issued Description of revision Page Edition

1 04.08.11 First printing All 01

2 04.11.25 CC100-20-ALR (Wishblade) parts added. 2-1,6-1,6-4 02

iiCC100-UM-251-9370

CONTENTS

1 PARTS NAMES and FUNCTIONS ................................ 1-1

2 RECOMMENDED PARTS LIST ..................................... 2-1

3 LIST OF TOOLS ............................................................ 3-1

4 DISASSEMBLY AND REASSEMBLY ............................ 4-1

4.1 How to Replace the Left Side Cover .................................................4-1

4.2 How to Replace the Top Cover .........................................................4-2

4.3 How to Replace the Right Side Cover ..............................................4-3

4.4 How to Replace the Front Guide .......................................................4-4

4.5 How to Replace the Rear Guide ........................................................4-5

4.6 How to Replace the Feed Guide .......................................................4-6

4.7 How to Replace the Pinch Roller Shaft Assembly ..........................4-7

4.8 How to Replace the Y Motor ..............................................................4-8

4.9 How to Replace the X Motor ..............................................................4-9

4.10 How to Replace the Feed Roller .....................................................4-10

4.11 How to Replace the Main Board .....................................................4-12

4.12 How to Replace the Y Belt ...............................................................4-14

4.13 How to Replace the Carriage Unit ..................................................4-15

4.14 How to Replace the Y Flexible Cable .............................................4-16

4.15 How to Replace the Solenoid ..........................................................4-18

4.16 How to Replace the Auto-Registration Mark Sensor Board .........4-19

5 ELECTRICAL ADJUSTMENTS ..................................... 5-1

5.1 Updating the System Firmware ........................................................5-1

5.2 DIP Switch Settings ...........................................................................5-3

5.3 Clearing the Non-Volatile RAM .........................................................5-3

5.4 Using the Adjustment Software ........................................................5-4

iiiCC100-UM-251-9370

5.5 Adjusting the Pen Force ....................................................................5-6

5.6 Adjusting the Auto-Registration Mark Sensor Sensitivity .............5-8

5.7 Adjusting the Offset of the Auto-Registration Mark Sensor ..........5-9

5.8 Adjusting the Distance Accuracy ...................................................5-10

6 PARTS LIST ..................................................................... 6-1

6.1 Main Unit Parts ...................................................................................6-1

6.2 Carriage ...............................................................................................6-3

6.3 Other ....................................................................................................6-4

7 BLOCK DIAGRAM ........................................................... 7-1

1-1

1 PARTS NAMES and FUNCTIONS

1 PARTS NAMES and FUNCTIONS

AC adapter jack

Pen carriage

Working table

Media roller

Cutting mat

Guide line

USB interface connector

Push roller

Standby switch

Plunger holder

Ball-point pen plunger

Feed knob

LED lamp

Pen carriage ........................ Drives the cutter pen to the left or right

Ball-point pen plunger ........ Used to plot using a ball-point pen

Plunger holder .................... Holds the cutter pen and drives it in the vertical direction

Standby switch ................... Used to set media in place, and to start or stop the main unit

Feed knob .......................... Drives media back and forth

USB interface connector ..... Used to connect the USB cable

AC adapter jack .................. Used to connect the cable for the AC adapter

Cutting mat ......................... Cutting or plotting work is performed on it

Push roller ........................... Pushes down on the media to hold it in place

Media roller ......................... Carries media

Working table ....................... Work is performed on it

Guide line ........................... Used as a guide when media is set in place

LED lamp ............................. Lights up when the unit is ready to operate and flashes when data is received

2-1

2 RECOMMENDED PARTS LIST

CC100-UM-251-9370

2 RECOMMENDED PARTS LIST

No. Part No. Description QTY Remarks

1 796212000 Main Board Assembly 1

2 796212001 Pen Carriage Assembly 1

3 796212002 Pinch Roller Assembly 1

796212006 Pinch Roller Assembly, Letter 1 For USA model.

4 796212003 Carriage Board Assembly 1

5 796212004 Auto Registration Mark Sensor Assembly 1

6 682124050 Standby Switch 1 PR304505

7 621240200 Motor Gear Assembly 2

Common part for X and Y

8 692124120 Flexible Cable for Auto Registration Mark Sensor 1 FPC304502

9 692124112 Y Flexible Cable 1 FPC304501B

10 796212005 Y Home Sensor Assembly 1 D3C-2220

11 621242001 Feed Roller Shaft 1

621240410 Feed Roller Shaft, Letter 1 For USA model.

12 621242030 X Feed Gear 1

13 621243051 Y Belt 1 460TN15-7.0W

14 621243200 Y Drive Gear Pulley 1

15 621243221 Y Idler Pulley 1

16 500052392 AC adapter YC-1048GRC1208P 1 UL,117V

500052390 AC adapter YC-1048GRC1175P 1 CE, 220V

500052407 AC adapter YC-1048GRC1210P 1 CCC, 240V

500052418 AC adapter YC-1048GRC1247P 1 BS, 240V

500051951 AC adapter SA45-3129 1 Japanese,100V

3-1

3 LIST OF TOOLS

CC100-UM-251-9370

3 LIST OF TOOLS

No. Adjustment Item Jig Tool

1 Firmware update Verup.exe (Firmware update program file) PC, USB I/F cable

2 Pen force adjustment Blade and blade holder, optionset.exe

(Electrical adjustment program)

Colex gauge (150 g, 300 g), PC,

USB I/F cable

3 Distance adjustment Blade and blade holder, optionset.exe

(Electrical adjustment program)

Glass scale 300 mm, PC, USB I/F

cable

4Auto Registration adjust-

ment

Blade and blade holder, optionset.exe

(Electrical adjustment program)

PC, USB I/F cable

4-1

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4 DISASSEMBLY AND REASSEMBLY

4.1 How to Replace the Left Side Cover

Disassembly

(1) Pull the feed knob from the left side of the unit, and then detach the feed knob.

Feed knob

Left side cover Top cover

M3L8 self-tapping screw

Hook

(2) Remove the two M3L8 self-tapping screws holding the left side cover.

(3) Release the bottom two hooks of the left side cover, and then detach the left side cover.

Hook

Hook hole

Release the hook here.

Reassembly

(1) To attach the left side cover, perform the above “Disassembly” procedure in reverse.

4-2

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.2 How to Replace the Top Cover

Disassembly

(1) Detach the left side cover (see Section 4.1).

(2) Pull out the top cover from the right side cover to detach the top cover.

Feed knob

Left side cover Top cover

Right side cover

M3L8 self-tapping screw

Hook

Reassembly

(1) To attach the top cover, perform the above “Disassembly” procedure in reverse.

4-3

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.3 How to Replace the Right Side Cover

Disassembly

(1) Remove the two M3L8 self-tapping screws holding the right side cover.

Note: Hold the right side cover after you have removed the screws; there is a flexible cable inside the cover.

Feed knob

Left side cover Top cover

Right side cover

M3L8 self-tapping screw

M3L8 self-tapping screw

Hook

(2) Release the bottom two hooks of the right side cover, and then detach the right side cover.

Hook

Hook hole

Release the hook here.

Reassembly

(1) To attach the right side cover, perform the above “Disassembly” procedure in reverse.

4-4

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.4 How to Replace the Front Guide

Disassembly

(1) Detach the left side cover (see Section 4.1).

(2) Detach the top cover (see Section 4.2).

(3) Detach the right side cover (see Section 4.3).

(4) Remove the two M3L6 pan head screws holding the front guide, and then detach the front guide.

Front guide M3L6 pan head screw

Note: Do not scratch the main frame when you are detaching the front guide.

Reassembly

(1) To attach the front guide, perform the above “Disassembly” procedure in reverse.

4-5

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.5 How to Replace the Rear Guide

Disassembly

(1) Detach the left side cover (see Section 4.1).

(2) Detach the top cover (see Section 4.2).

(3) Detach the right side cover (see Section 4.3).

(4) Remove the three M3L6 pan head screws holding the rear guide, and then detach the rear guide.

Rear guide

M3L6 pan head screw

Reassembly

(1) To attach the rear guide, perform the above “Disassembly” procedure in reverse.

4-6

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.6 How to Replace the Feed Guide

Disassembly

(1) Detach the left side cover (see Section 4.1).

(2) Detach the top cover (see Section 4.2).

(3) Detach the right side cover (see Section 4.3).

(4) Remove the two M3L8 pan head screws holding the ball-point pen plunger holder with the limiter bracket, and

then detach the ball-point pen plunger holder and the limiter bracket.

M3L8 pan head screw

Feed guide

M3L6 pan head screw

Limiter bracket

Ball-point pen plunger holder

(5) Remove the M3L6 pan head screw holding the feed guide, and then detach the feed guide.

Reassembly

(1) To attach the feed guide, perform the above “Disassembly” procedure in reverse.

4-7

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.7 How to Replace the Pinch Roller Shaft Assembly

Disassembly

(1) Detach the left side cover (see Section 4.1).

(2) Detach the top cover (see Section 4.2).

(3) Detach the right side cover (see Section 4.3).

(4) Detach the two pressure springs from the pressure bracket.

Pressure spring

Pressure bracket

(5) Lift up both sides of the pressure bracket, slide the pressure shaft assembly to the left side, and then detach

the pressure shaft assembly from the right side.

Pressure shaft assembly

Pressure bracket

Reassembly

(1) To attach the pinch roller shaft assembly, perform the above “Disassembly” procedure in reverse.

4-8

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.8 How to Replace the Y Motor

Disassembly

(1) Detach the left side cover (see Section 4.1).

(2) Detach the top cover (see Section 4.2).

(3) Detach the right side cover (see Section 4.3).

(4) Detach the two pressure springs from the pressure bracket (see Section 4.7).

(5) Detach the rear guide (see Section 4.5).

(6) Disconnect the Y motor cable which is connected to J5 on the main board.

(7) Remove the two M3L6 TP head screws holding the Y motor, and then detach the Y motor.

Y motor M3L6 TP head screw

M3L6 TP head screw

X motor

Reassembly

(1) To attach the Y motor, perform the above “Disassembly” procedure in reverse.

4-9

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.9 How to Replace the X Motor

Disassembly

(1) Detach the left side cover (see Section 4.1).

(2) Detach the top cover (see Section 4.2).

(3) Detach the right side cover (see Section 4.3).

(4) Detach the two pressure springs from the pressure bracket (see Section 4.7).

(5) Detach the rear guide (see Section 4.5).

(6) Disconnect the X motor cable which is connected to J4 on the main board.

(7) Remove the two M3L6 TP head screws holding the X motor, and then detach the X motor.

Y motor M3L6 TP head screw

M3L6 TP head screw

X motor

Reassembly

(1) To attach the X motor, perform the above “Disassembly” procedure in reverse.

4-10

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.10 How to Replace the Feed Roller

Disassembly

(1) Detach the left side cover (see Section 4.1).

(2) Detach the top cover (see Section 4.2).

(3) Detach the right side cover (see Section 4.3).

(4) Detach the two pressure springs from the pressure bracket (see Section 4.7).

(5) Detach the front guide (see Section 4.4).

(6) Detach the Y motor (see Section 4.8).

(7) Remove the M3L6 flat head screw and the M3L6 pan head screw holding the motor bracket, and then detach

the motor bracket.

M3L6 TP head screw

Y motor

M3L6 flat head screw

Motor bracket

Feed roller

Feed roller gear

M3L6 pan head screw

(6) Disconnect the X motor cable which is connected to J4 on the main board.

4-11

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

(7) Remove the two M3L8 TP head screws holding the Y motor, and then detach the Y motor.

Collar

M3L6 pan head screw

Bearing

Feed roller

X feed roller gear

E-ring

(8) Remove the M3L6 pan head screw holding the X feed roller gear, and then detach the X feed roller gear.

(9) Detach the E-ring from the left side of the feed roller.

(10) Detach the two bearings and the collar from the feed roller, and then detach the feed roller from the main unit.

Reassembly

(1) To attach the feed roller, perform the above “Disassembly” procedure in reverse.

4-12

4 DISASSEMBLY AMD REASSEMBLY

CC100-UM-251-9370

4.11 How to Replace the Main Board

Disassembly

(1) Detach the left side cover (see Section 4.1).

(2) Detach the top cover (see Section 4.2).

(3) Detach the right side cover (see Section 4.3).

(4) Detach the front guide (see Section 4.4).

(5) Detach the rear guide (see Section 4.5).

(6) Remove the two M3L6 pan head screws holding the guide rail, and then detach the guide rail.

M3L6 pan head screw

Flexible cable clamp

Guide rail

(7) Detach the three flexible cable clamps from the guide rail, and then detach the Y flexible cable from the guide

rail.

(8) Disconnect all the cables from the main board (J2, J4, J5, J8, J9).

Other manuals for Craft ROBO CC100-20

1

Table of contents

Other GRAPHTEC Printer manuals

GRAPHTEC

GRAPHTEC JW220-06 User manual

GRAPHTEC

GRAPHTEC DP-581H Parts list manual

GRAPHTEC

GRAPHTEC SignJet JS310-25ES User manual

GRAPHTEC

GRAPHTEC JS500 User manual

GRAPHTEC

GRAPHTEC SignJet JS310 Series Installation and operation manual

GRAPHTEC

GRAPHTEC SignJet JS310 Series User manual

GRAPHTEC

GRAPHTEC JS500 User manual

Popular Printer manuals by other brands

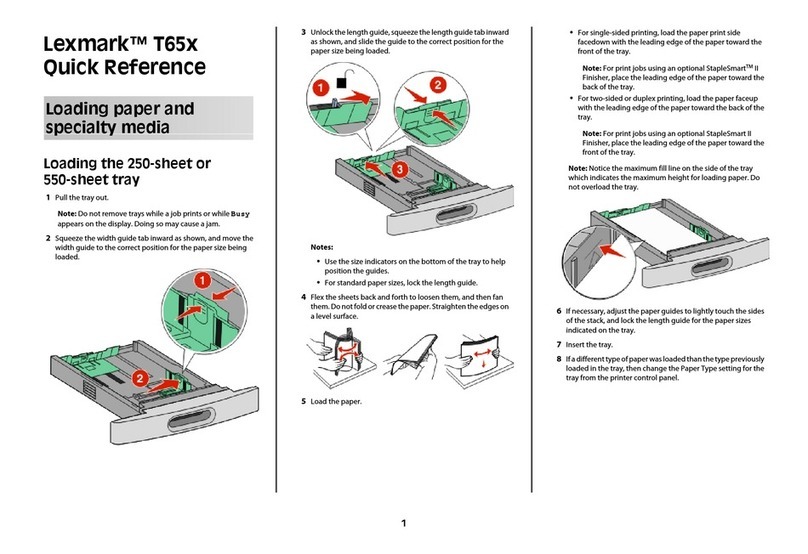

Lexmark

Lexmark T650dtn quick reference

Toshiba

Toshiba TEC B-850 Series Key Operation Specification

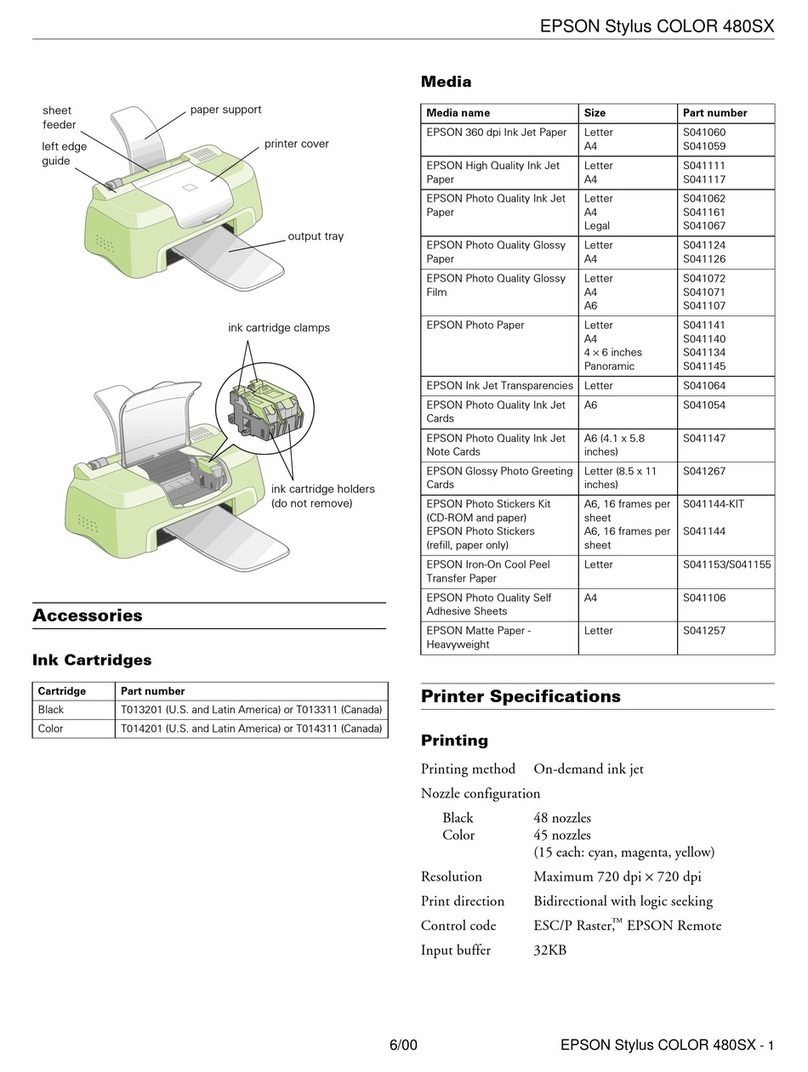

Epson

Epson Stylus COLOR 480/480SX - Stylus Color 480SX Ink Jet... Installation & operation

Samsung

Samsung ML 2851ND - B/W Laser Printer Manual Del Usuario

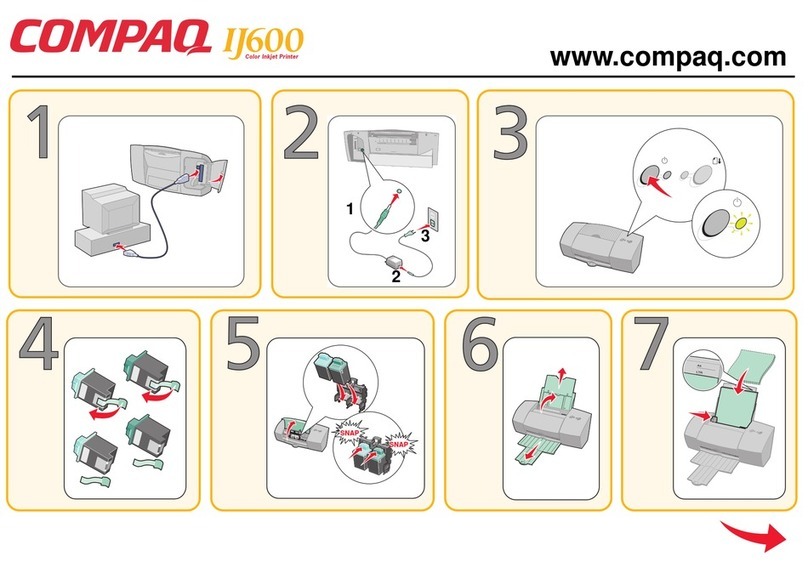

Compaq

Compaq Inkjet IJ600 quick start guide

ANDIG

ANDIG WSP-i450 manual