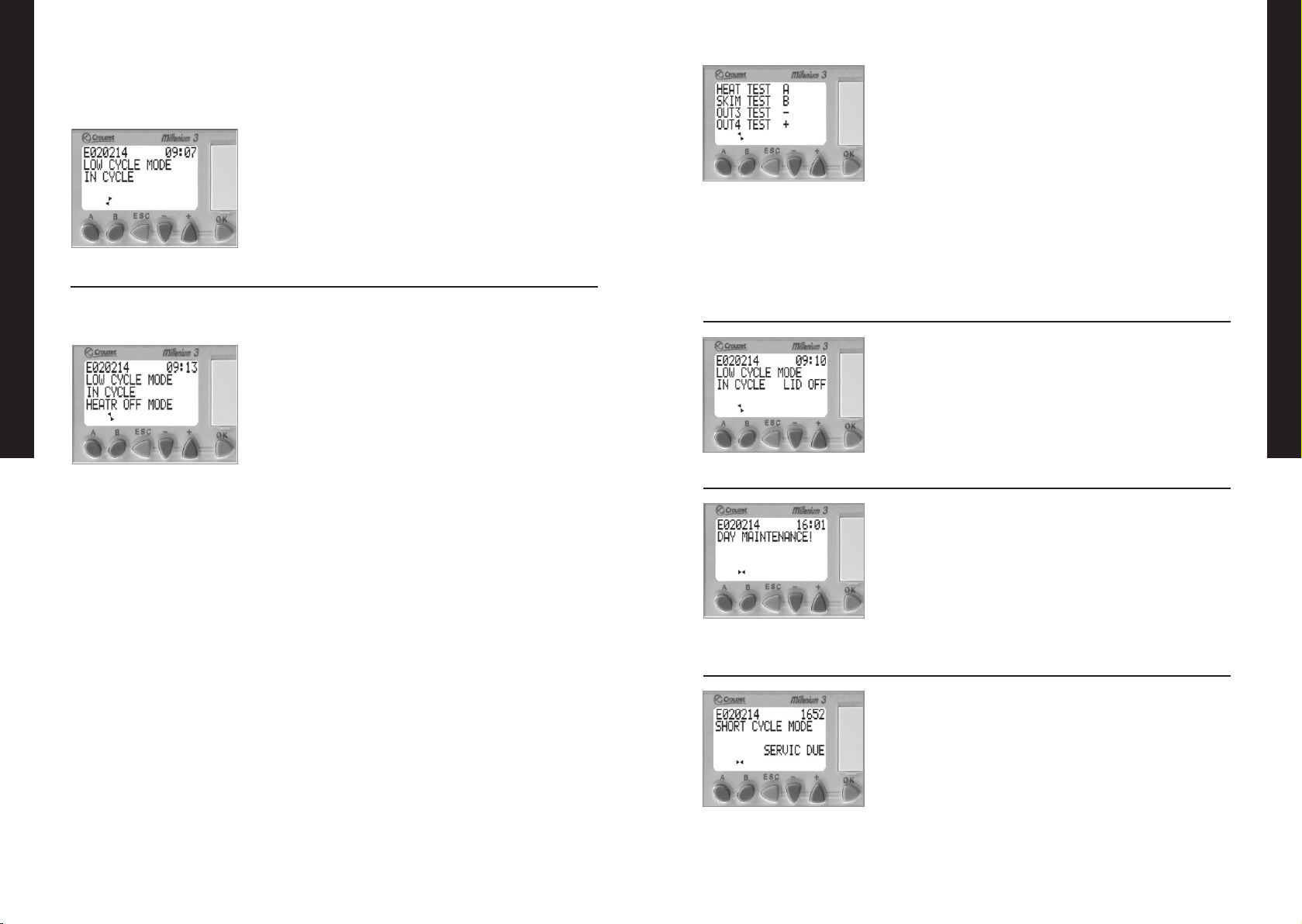

6 7

Initial Note: if no user adjustments are made a

factory setting from 8am-12pm starts the unit on

a LOW cycle daily. This is adequate for smaller

applications including out of town delis, or small

restaurants of less than 50 people.

Otherwise refer to Appendix 1 at back of this manual

for recommended settings for your application.

After machine switch-on, the home screen appears

displaying the controller software version (in this case

E for Europe and version date ddmmyy). The current

time of day, and factory set cycle mode ARE also

displayed.

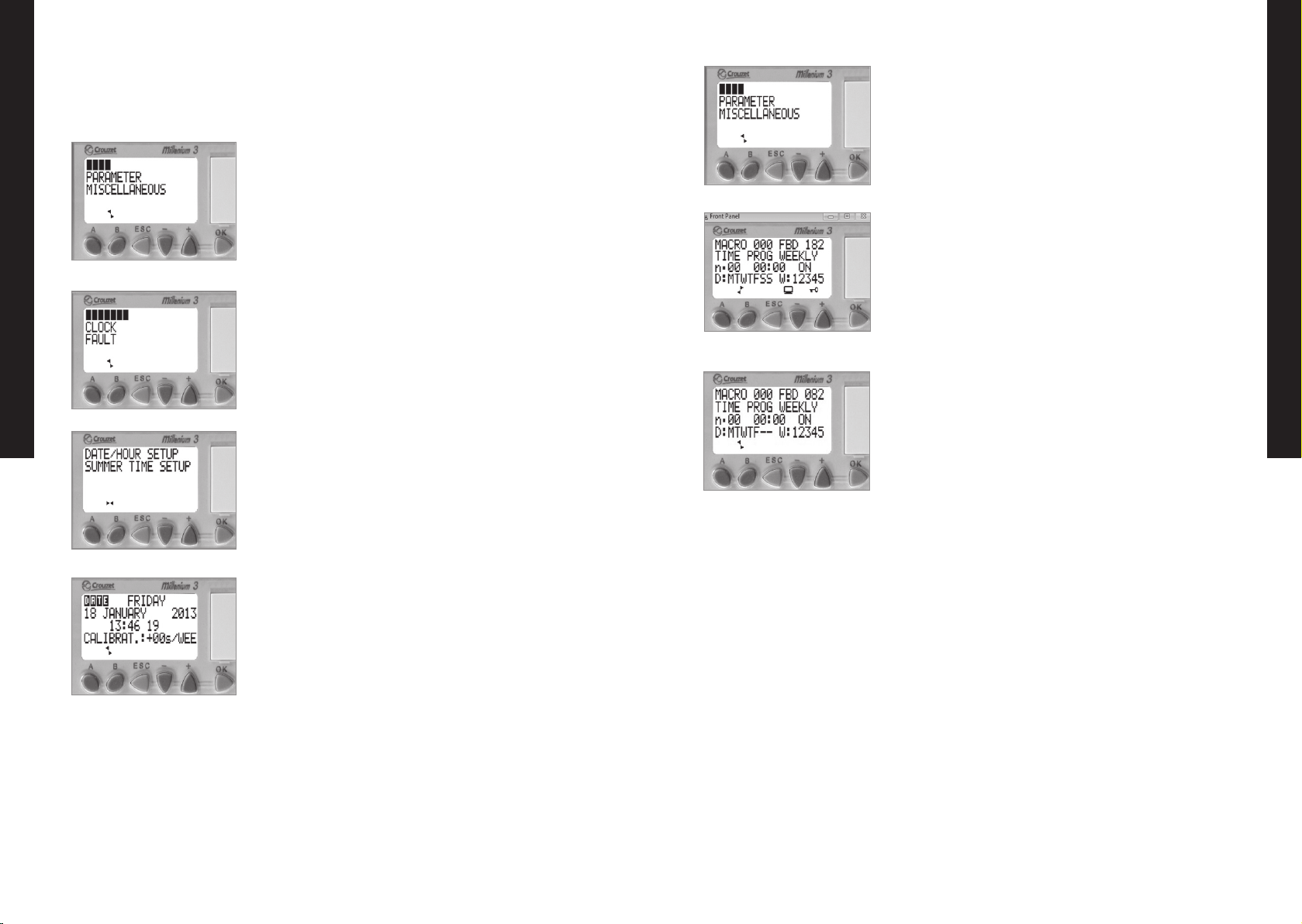

To change a cycle rst choose from one or more of

the 4 hour programs 08:00-12:00, 12:00-16:00, 16:00-

20:00, and 20:00–00:00, accessed by pressing the OK

and A buttons together. Then advance through the

time slots available by re-pressing A.

Any time-slot can be set to ON/OFF by pressing the B

button. On completion press ESC to return to the

home Screen.

Finally in the home screen press and hold either the +

or - keys for 1 second to ne tune the cycle duration.

The display will indicate the adjustment made from

3 options

- LOW Cycle Mode

- MEDIUM Cycle Mode

- HIGH Cycle Mode

Grease Guardian Controller

TIME CONTROL SETTING

Cycle Programming

See Appendix 1 for suggested setting for your application

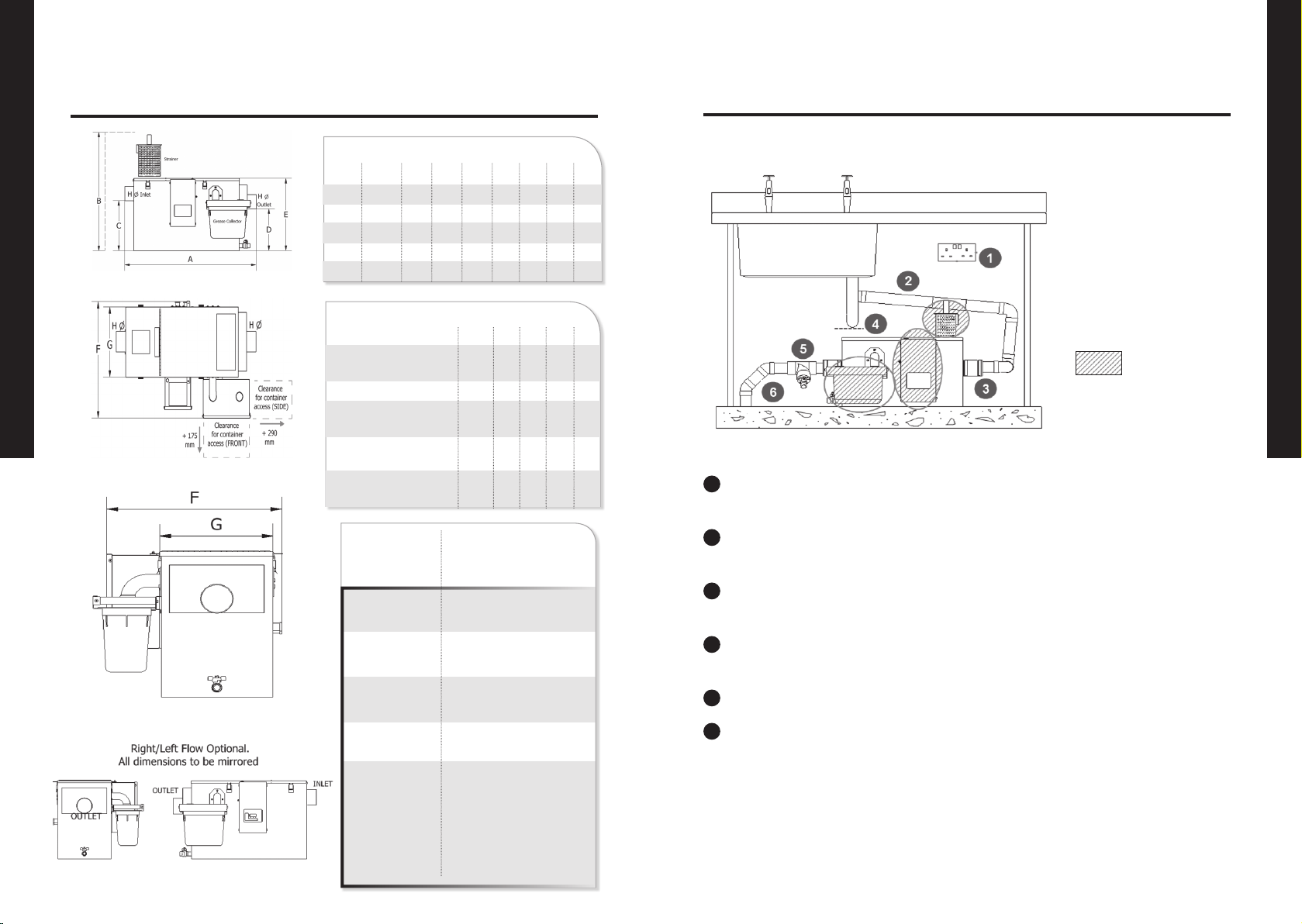

1 Ensure unit is positioned on a level surface only and is plumbed in securely.

2 Ensure electrical outlet is waterproof and is tted with or supported by a

dedicated Residual Current Device or ground fault circuit breaker rated 30mA

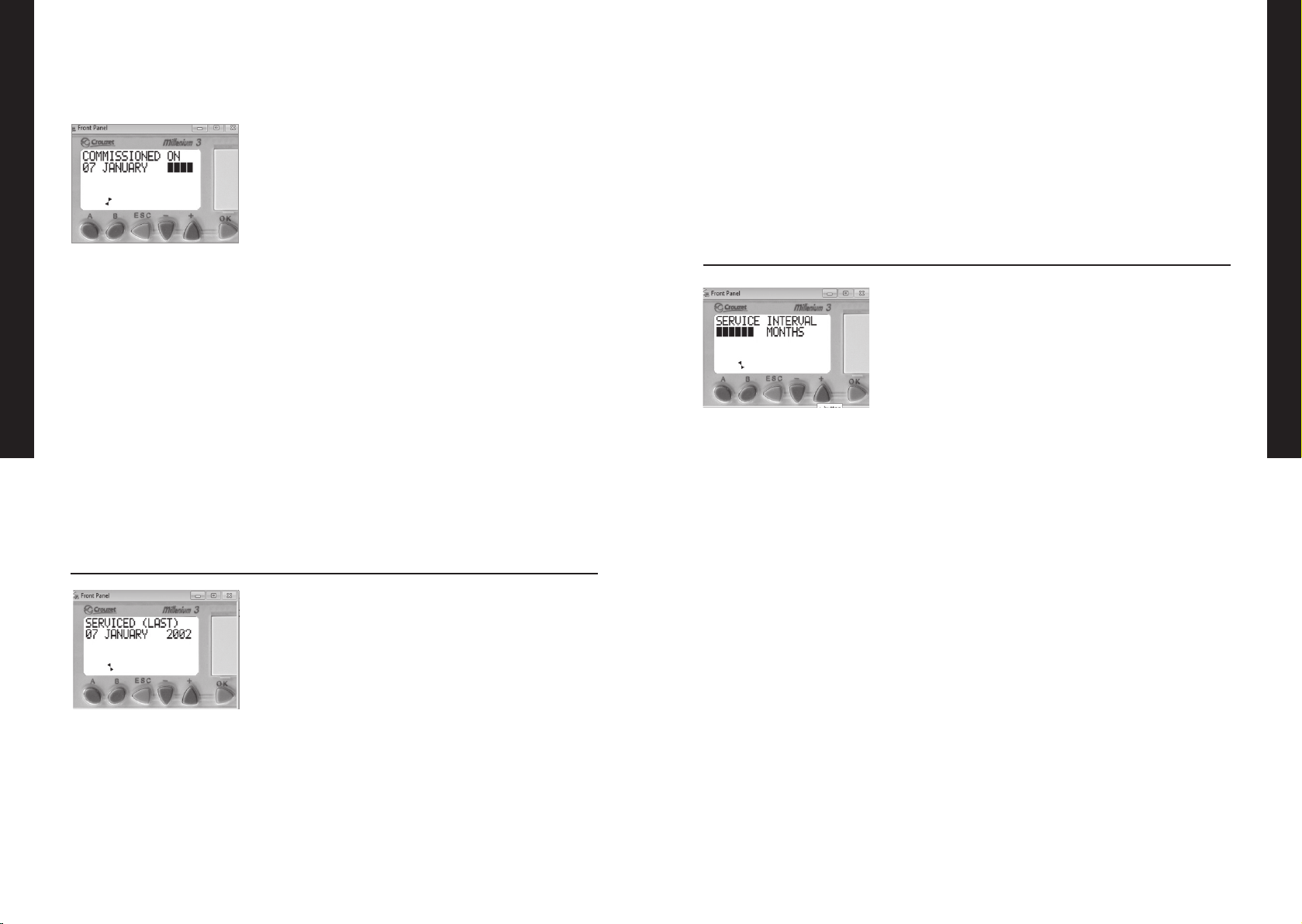

Points 3 and 4 below should normally be carried out by your market

representative as part of unit commissioning:

3 Prior to mains switch-on ensure the unit is lled with water to the correct

settlement level which occurs when the inowing water stabilises at the base of

the skimming wheel.

4 Set the controller time of day and appropriate cycle programme in accordance

with timer setting instructions detailed in this manual. Observe all

maintenance requirements detailed in this manual

HEALTH, SAFETY AND EFFICIENCY

• Never turn unit on before lling

with water as instructed above.

• Disconnect unit from mains

before accessing any electrical

components

• Unit will lose efciency if not

Maintained.

• The unit is designed to trap and

remove free oating grease oils

and fats only

• The internal solids strainer

provided protects the unit from

coarse solid food waste build

up. To help ensure the highest

efciency and reduce ner solid

food-waste please install primary

strainers in sinks and ensure food

waste is scraped to bin before

washing utensils

• Do not use Hazardous detergents

to clean unit

• Do not install unit externally

unless IP65 weather proof cover

is used

• Do not connect a macerator or

similar device upstream from the

Grease Guardian

• Ensure unit is level and installed

at on the ground or frame where

specied

• Remove blockages and grease

build up from drains before

installing the Grease Guardian

PART 2: PRE START UP CHECKS

INSTALLATION