8

the back of the unit. The hot water supply should preferably be ltered to

avoid any particles from entering the solenoid valves provided. The plumber

has to ensure that any plumbing of the tap water supply to the manifold

conforms with the local plumbing codes in particular to the provision of any

backow prevention devices, assemblies and methods to be used.

Single Phase Connection

The power cord of the unit is to be hardwired directly to a dedicated mains

outlet rated to handle electrical loads as described in the specications

table of this manual. Hardwired outlet must be tted with a double pole

switch. CAUTION: to provide continued protection against risk of electric

shock, connect to properly grounded outlets only. All electrical work must

be carried out by a qualied electrician.

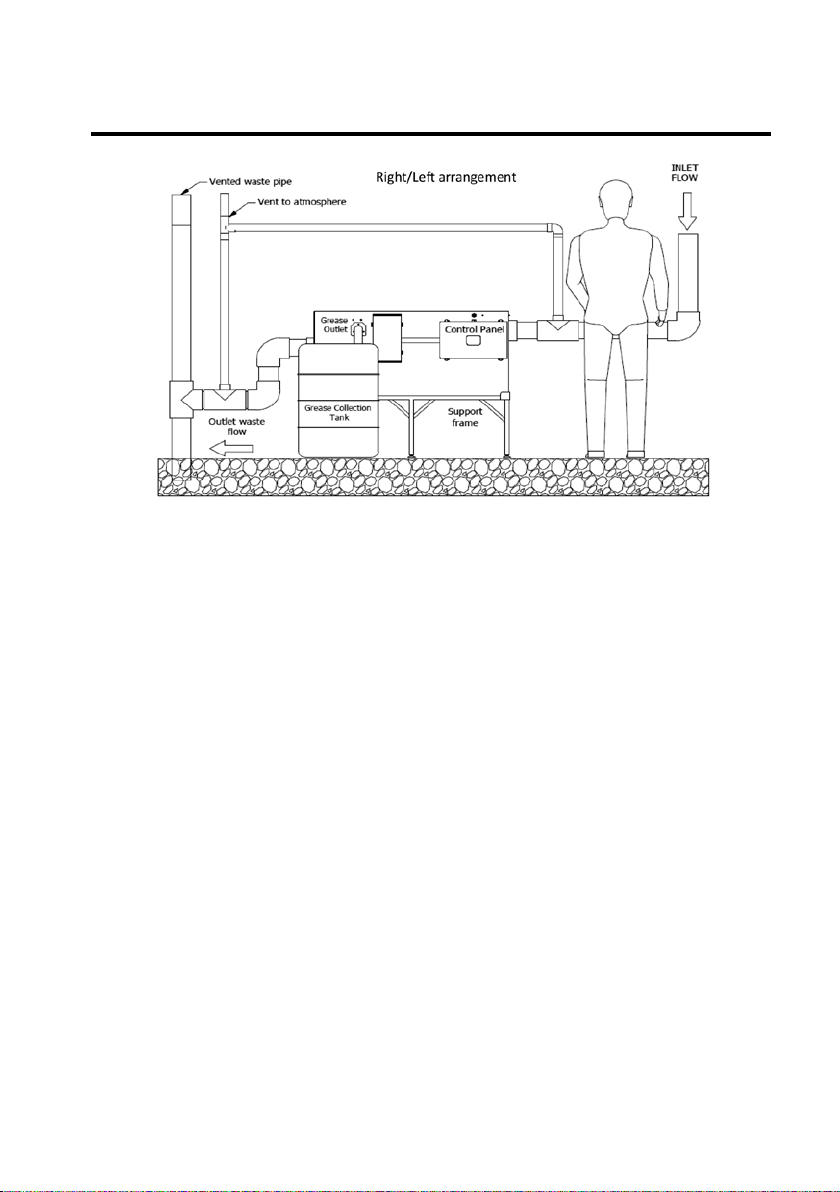

Venting

For the inlet piping, a pipe vent (or code approved air admitance valve)

which is at least 1/2 the inlet pipe diameter should be connected. An

additional pipe vent (or code approved air admitance valve) which is at least

1/2 the outlet pipe diameter should be connected to the outlet pipe of

the system and located as close as possible to the Grease Guardian outlet

connection. It is always preferable to have vent pipes used for each Grease

Guardian system connected to one common vent pipe and venting directly

to atmosphere rather than combining these with other waste pipe vents.

This method eliminates the possibility that odors from other other xtures

making their way back into the Grease Guardian unit.

Room ventilation

Odors will be minimised via the correct venting method above. However

air extraction fan systems should be installed in more conned locations of

less than 4m3. Such a system should also be installed in ANY location where

personnel are working close to the System location.

Operating Temperature

Ofcial room temperature range for safe electrical operation of this system

as required under the appropriate UL standard is between 0 and 35 degrees

C (32 - 95 F). However for optimal grease removal the room temperature

should be maintained at 10 and 35 degrees (50 - 95 F). This will reduce the

risk of grease solidifying on the skimming mechanisms.

All instructions and drawings provided in this booklet are for reference only.

The unit provided is tobe installed in compliance with the local legislation,

regulation and codes. Installation by a qualied plumber knowledgeable with

the local plumbing code is necessary.