7

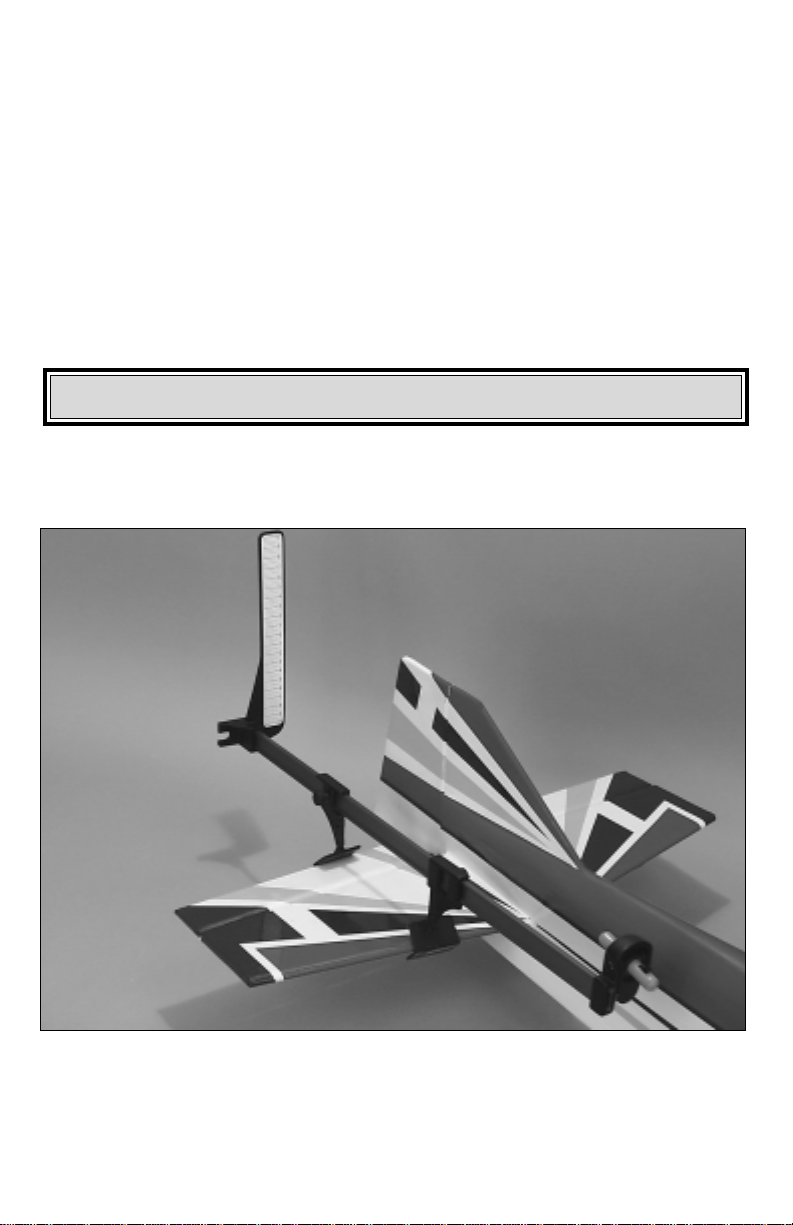

3. Without bumping the laser assembly, attach the meter to the wing close to the fuse-

lage. If the meter is attached to an aileron, make sure the aileron stays

at neutral.

4. Let the laser come to rest and note the reading.

5. Check the other wing panel near the fuselage as well. Any difference measured

between the two sides of the wing could indicate a misalignment during wing joining

or an inaccurate wing saddle.

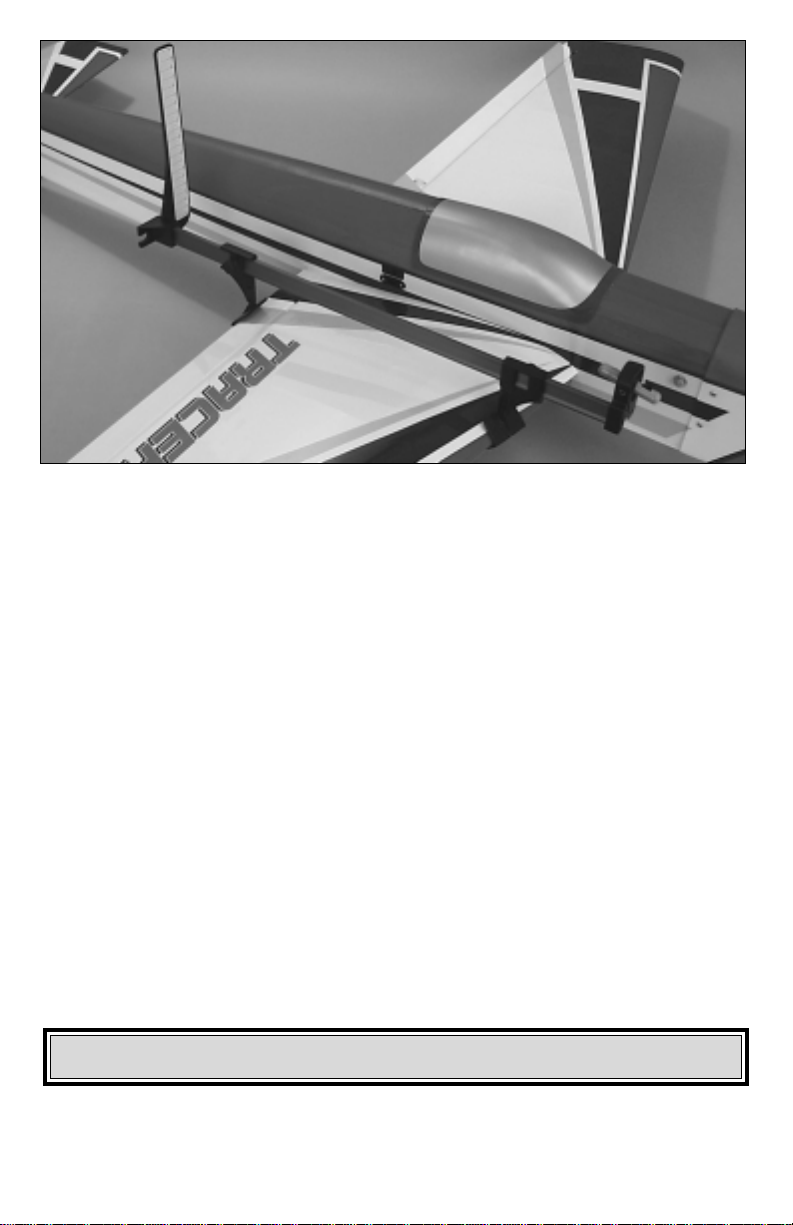

6. If your model is in the framed up stage, then it is easy to sand the wing or stab sad-

dle as needed to get the correct readings. If your plane is finished, shimming the wing

saddle is your the best course of action to correct the incidence. Changing the

Stabilizer incidence on a finished model entails cutting out the stab, adjusting the stab

saddle and reattaching. This is rather difficult and should not be attempted unless the

problem is severe. An easier solution is to shim the wing so that the incidence differ-

ence between the stab and wing matches the designer’s

specs. If you do this, howev-

er, make sure that the engine down thrust angle is

correct. It will most likely have to

change a bit to correspond to the new wing angle.

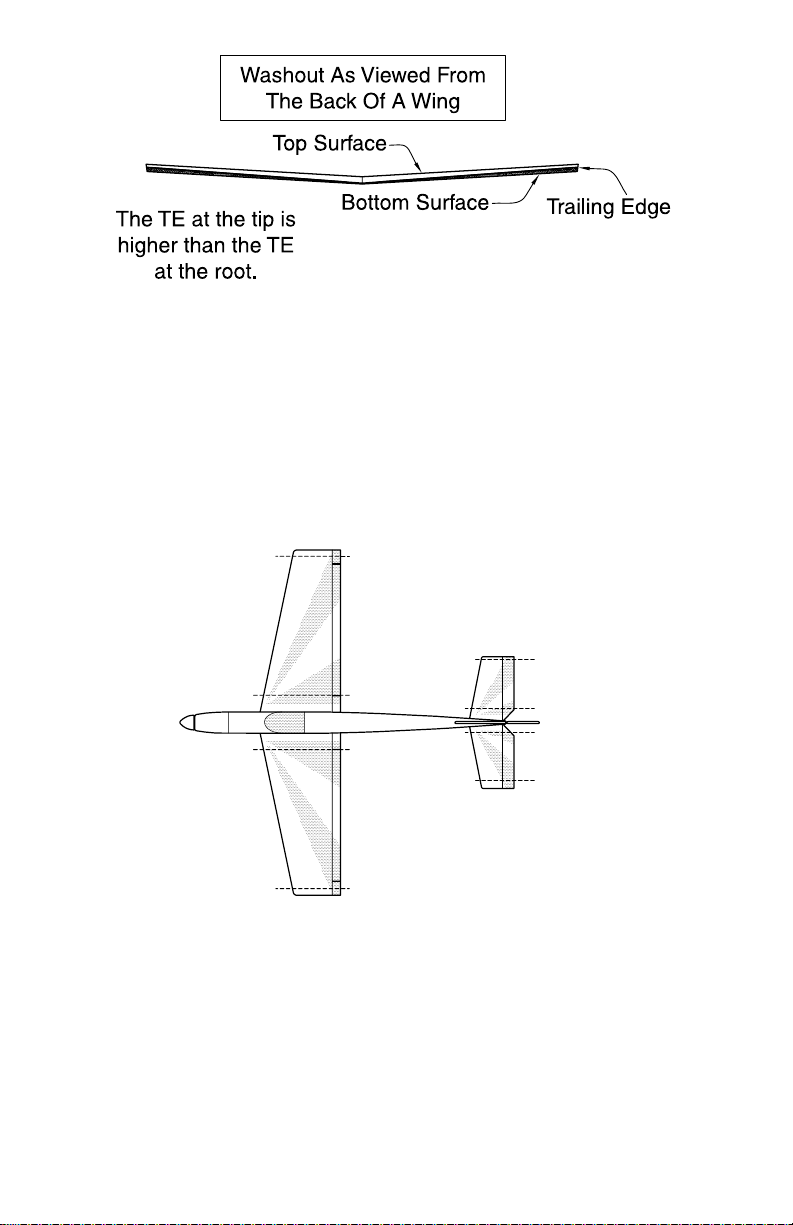

One of the most common problems with model aircraft is wing twist. Wing twist can

cause trim difficulties at different speeds, poor stall characteristics and other general

tracking problems.

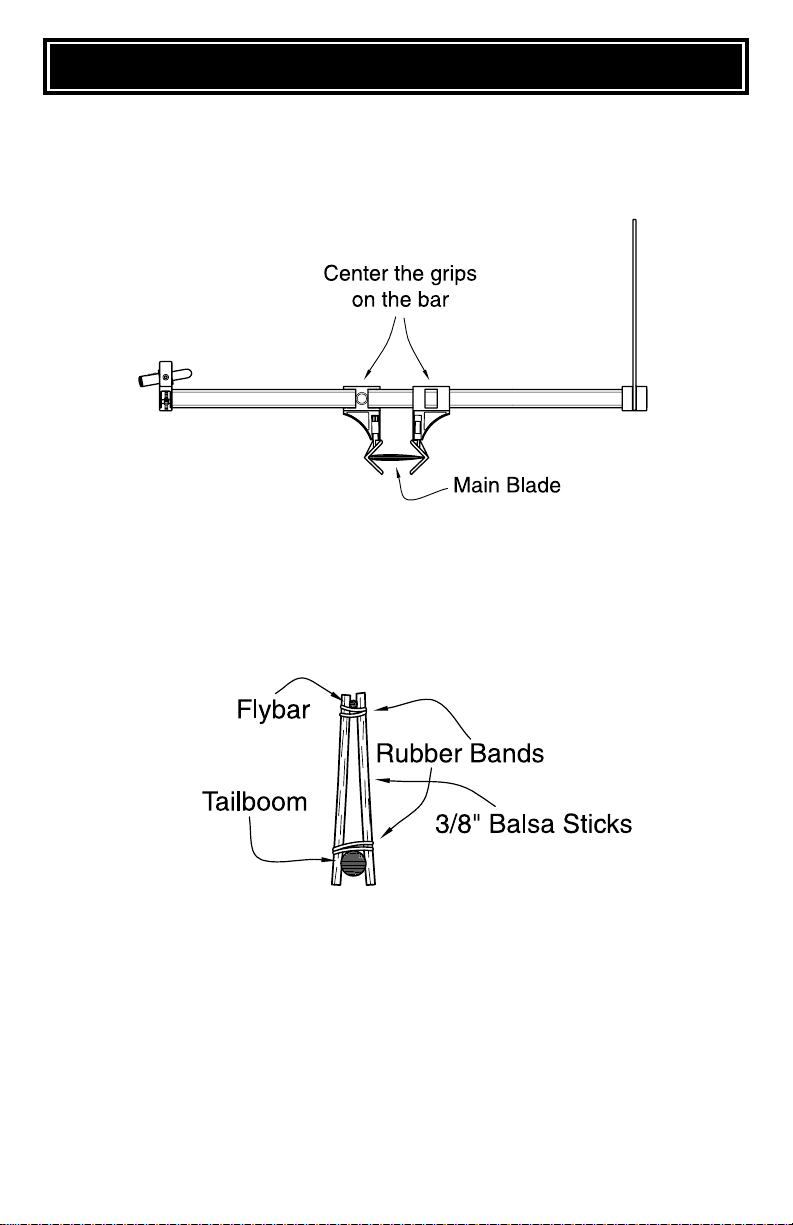

Checking Wing/Stabilizer Twist