Important Features of S-700

AERODYNAMICS & ELECTRONICS & TELEVISION

Smallest and Most Powerful: With the highly efficient blades, controller and alternator,

S-700 can provide the maximum output power in the world at the same size, weight

and rotor diameter.

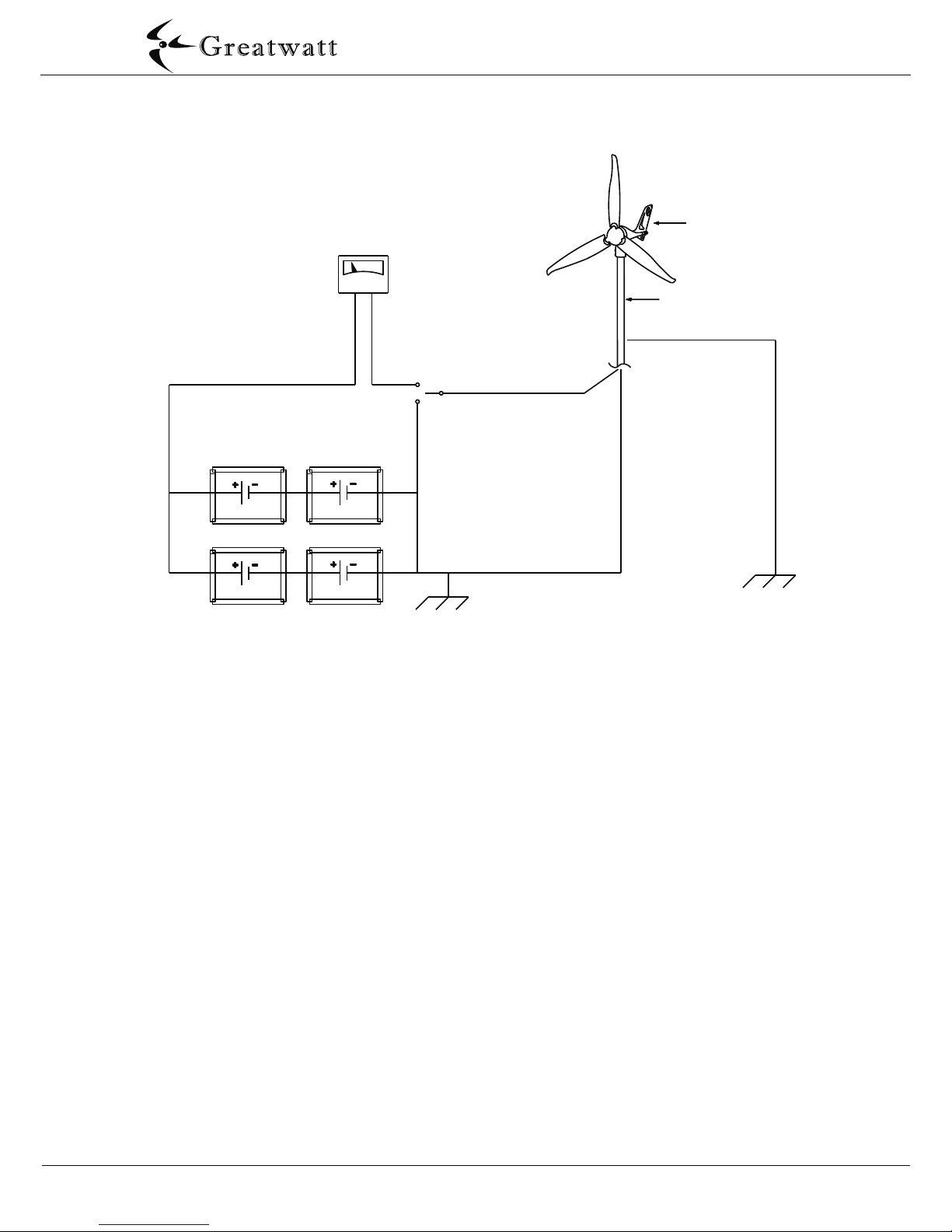

Whole Protection: S-700 provide the best protection, for example, the voltage

auto-brake, slow down in strong wind (Hysteresis Braking), shut down completely

in cyclone, battery charge protect, smart protect, overtemperature protect, and so on.

Over-speed Protection: To fully “utilize” wind power, the blades will not be braked

in the speed from 0m/s to 20m/s. Once the Wind Generator “sense” the wind speed

higher than 20m/s, it will shut down completely and stop charging.

Constant Current Charge: In the same wind speed condition, when the battery is

becoming fuller and fuller, the charging current of the common wind generator will

be less and less, but S-700 can always keep steady charging current, so it can fully

make use of the wind energy, and, at the same time, it can also effectively protect

your battery!

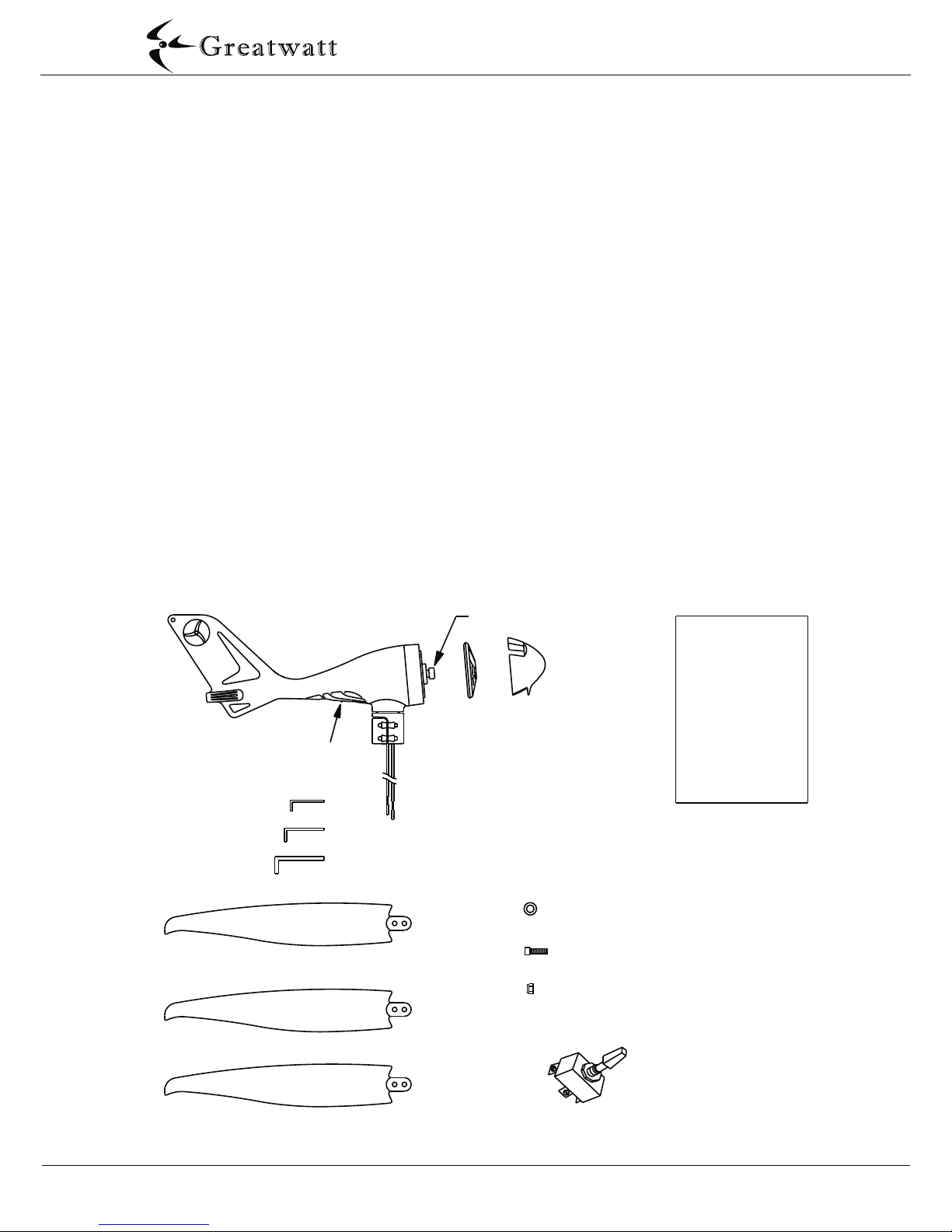

MATERIAL

CFRP Blades: The rotor blades are made of CFRP, and manufactured by precise

injection process, so S-700 has the rigidest, the best electric and the minimal

vibrant blades.

Magnalium Frameworks: All frameworks are made of magnalium, just as the body,

the face, the hub, the yaw shaft, etc. This material is very anticorrosive and very hard.

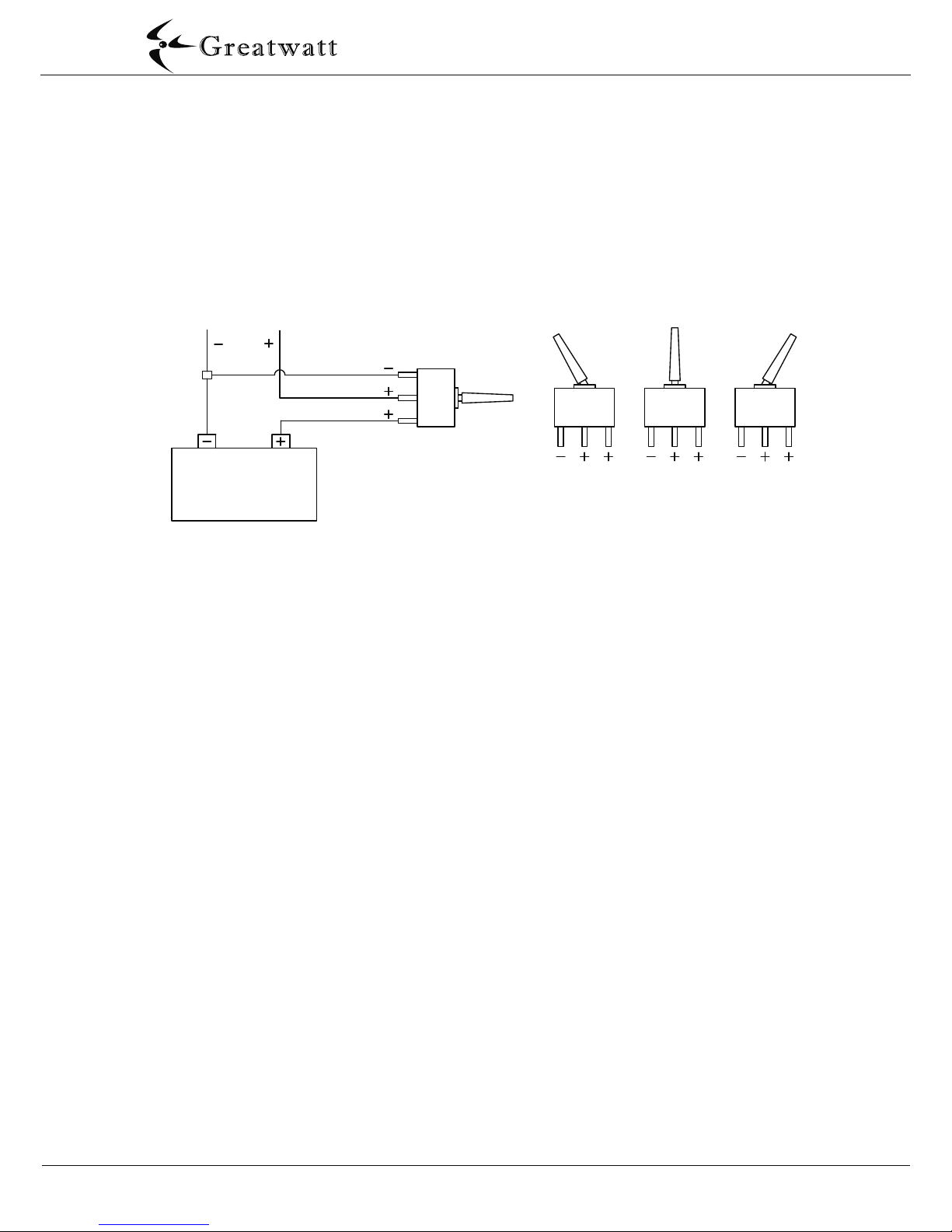

ACCESSORIES

Stop Switch: We provide a stop switch (50 amps D.C.), which can be used to “stop”

the Wind Generator for service or any other reason. You will find it very useful and

necessary.

Plastic Disk: The static electricity generated from blades rotating will corrode the

hub, especially used in the sea. We provide some plastic disks to protect the

hub from corrosion.

Page 1

http://www.greatwatt.com