2 3A8693B

Contents

Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Configuration Number Matrix . . . . . . . . . . . . . . . . . 5

Typical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Information . . . . . . . . . . . . . . . . . . . . . . . 7

Before First Use. . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Air Exhaust Ventilation. . . . . . . . . . . . . . . . . . . . . 8

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tips to Reduce Cavitation . . . . . . . . . . . . . . . . . 10

Orientation of Fluid Inlet and Outlet Ports . . . . . 11

Fluid Pressure Relief Valve . . . . . . . . . . . . . . . . 11

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure. . . . . . . . . . . . . . . . . 12

Flush Before Using Equipment . . . . . . . . . . . . . 12

Start and Adjust the Equipment . . . . . . . . . . . . . 12

Equipment Shutdown. . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Before Each Use . . . . . . . . . . . . . . . . . . . . . . . . 13

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Flushing and Storage. . . . . . . . . . . . . . . . . . . . . 13

Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . 13

End of Product Life. . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Check Valve Repair . . . . . . . . . . . . . . . . . . . . . . 16

Diaphragm Repair . . . . . . . . . . . . . . . . . . . . . . . 18

Air Valve Repair . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replace Bearing and Air Gasket . . . . . . . . . . . . 23

Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Air Section Parts. . . . . . . . . . . . . . . . . . . . . . . . . 25

Fluid Section Parts . . . . . . . . . . . . . . . . . . . . . . . 26

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . 28

Torque Instructions . . . . . . . . . . . . . . . . . . . . . . . . 29

Torque Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 30

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Technical Specifications . . . . . . . . . . . . . . . . . . . . 32

California Proposition 65 . . . . . . . . . . . . . . . . . . . . 33

Graco Standard Husky Pump Warranty . . . . . . . . 34

Graco Information. . . . . . . . . . . . . . . . . . . . . . . . . . 34

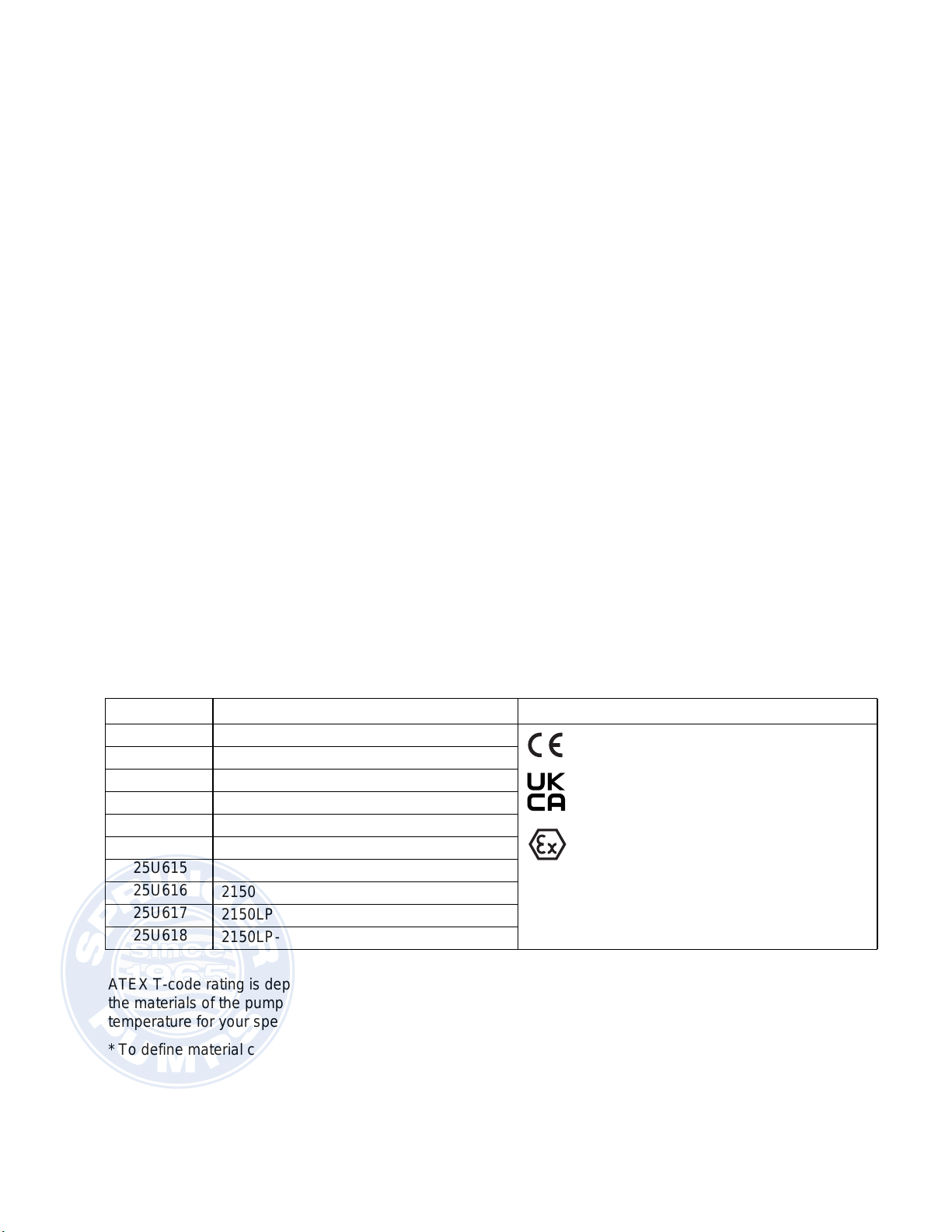

Models

Part Configuration Number* Approvals

25U609 2150LP-PA01AA1FB-BBNBN

25U610 2150LP-PA01AA1FB-BSPBN

25U611 2150LP-PA01AA1FB-BTPBN

25U612 2150LP-PA01AA1FB-BGEBN

25U613 2150LP-PA01AA1FB-BCRBN

25U614 2150LP-PA01AA2FB-BBNBN II 2 GD

Ex h IIC 66°C...82°C Gb

Ex h IIIC T82°C Db

25U615 2150LP-PA01AA2FB-BSPBN

25U616 2150LP-PA01AA2FB-BTPBN

25U617 2150LP-PA01AA2FB-BGEBN

25U618 2150LP-PA01AA2FB-BCRBN

ATEX T-code rating is dependent on the temperature of the fluid being pumped. Fluid temperature is limited by

the materials of the pump interior wetted parts. See Technical Specifications for the maximum fluid operating

temperature for your specific pump model.

* To define material codes, see Configuration Number Matrix, page 5.